Packaging arrangement of flip chip on thin film

A packaging structure and flip-chip technology, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of damage to the flip-chip 14 and the inability to achieve the best heat dissipation effect, so as to improve the strength, Effective dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

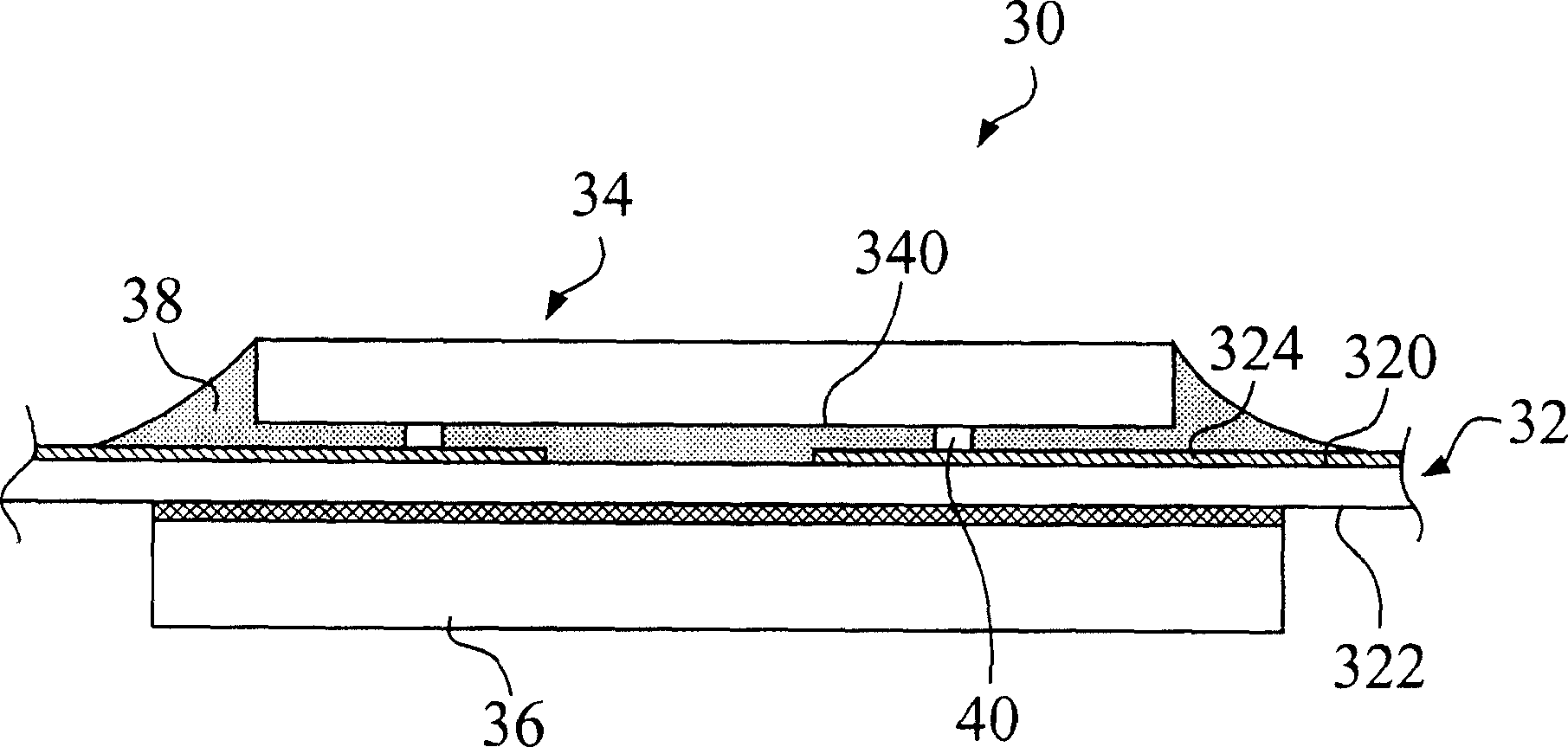

[0037] see figure 2 , figure 2 It is a schematic diagram of the Flip-Chip-on-Film packaging structure 30 according to the first preferred embodiment of the present invention. The Flip-chip-on-film package structure (Flip-chip-on-film package structure) 30 includes a flexible substrate (Flexible substrate) 32, a flip chip (Flip chip) 34, a first heat sink (Heat sink) 36 and a sealant (Sealant) 38. The flexible substrate 32 can be a polyimide (PI) substrate or other similar substrates with the same function. The flexible substrate 32 has an upper surface 320 , a lower surface 322 and a wiring layer 324 formed on the upper surface 320 . The flip chip 34 is fixed on the upper surface 320 of the flexible substrate 32, and has an active surface (Active surface) 340, at least one bump (Bump) 40 is formed on the active surface 340 and is connected to the flexible substrate 32. The wiring layer 324 forms electrical connections. The sealant 38 is coated between the flip chip 34 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com