High voltage power supply with digital control and digital control method thereof

A high-voltage power supply, digital control technology, applied in the field of high-voltage voltage, can solve a lot of work and time problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0030] A high voltage power supply (HVPS) according to an exemplary embodiment of the present invention includes a combination of a digital control chip or ASIC capable of intermittently conducting a current in a primary side coil of a transformer and various analog components. In the exemplary embodiments of the present invention described below, an ASIC chip driving 4 channels is described, but the embodiments of the present invention are not limited thereto.

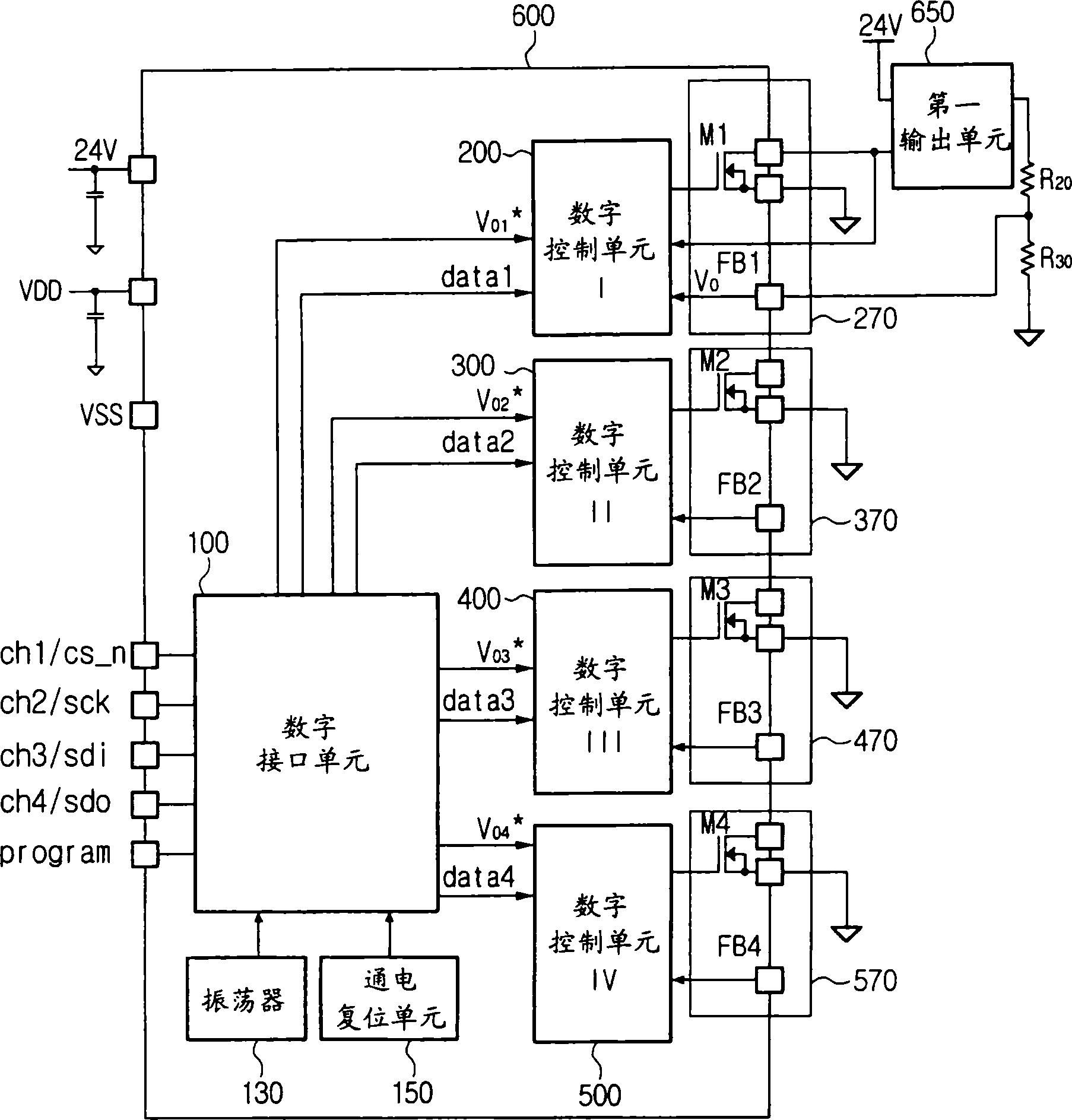

[0031] image 3 is a block diagram of an HVPS according to an exemplary embodiment of the present invention.

[0032] refer to image 3 , the HVPS includes a digital interface unit 100, an oscillator 130, a power-on reset unit 150, first to fourth digital control units 200, 300, 400, and 500, and first to fourth switching elements 270, 370, 470 and 570, which are offered as single-chip ASIC 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com