Ladle lining structure and slag preventing paint

A molten iron tank and anti-slagging technology, applied in the field of molten iron tanks and coatings, can solve the problems of waste materials, weak affinity of iron slag, waste of refractory materials, etc., and achieve the effects of prolonging the slag mixing time, reducing production costs and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

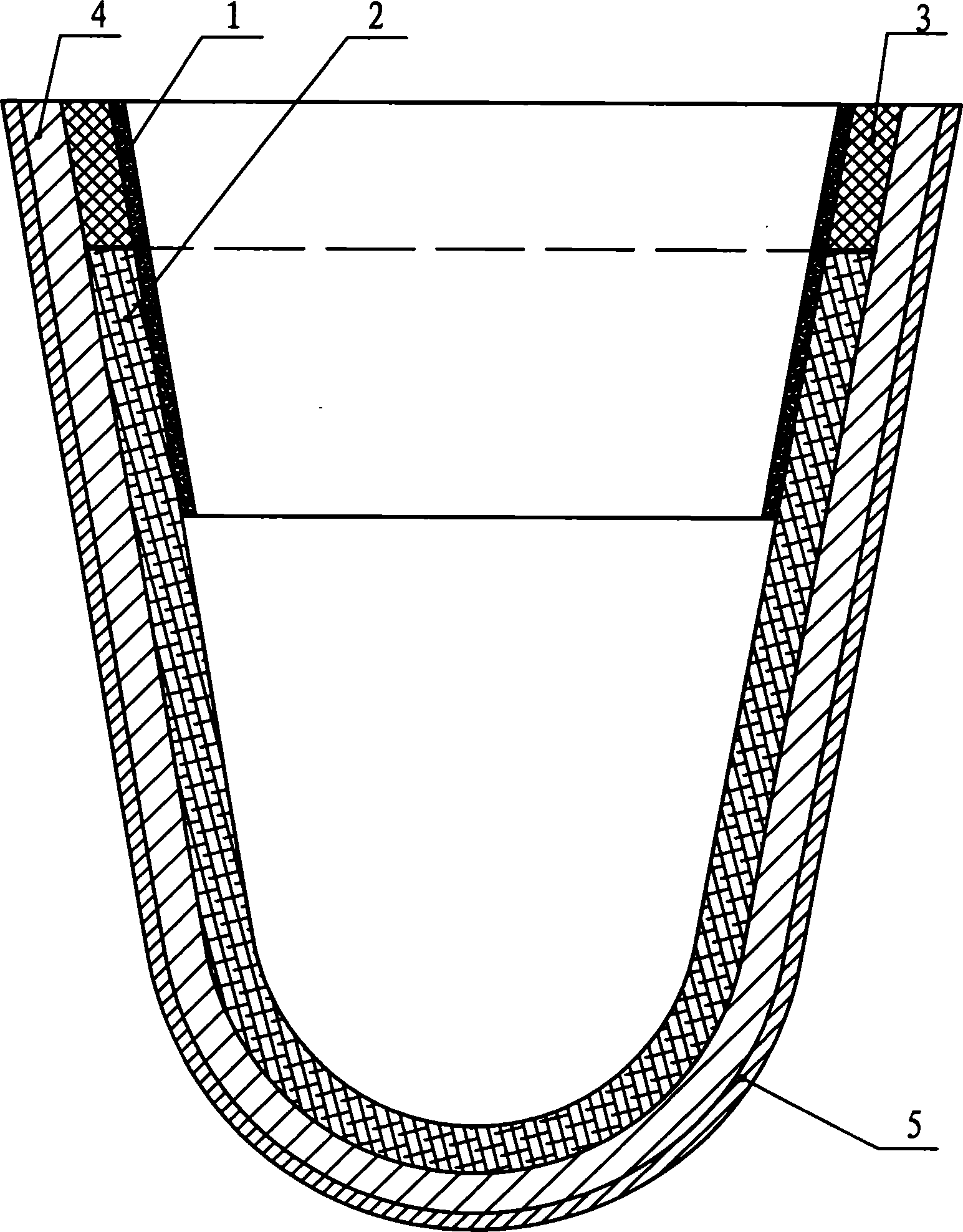

[0031] Embodiment 1: See Figure 1, the structure of the new anti-slagging molten iron tank in the figure, from the inside to the outside is the working lining, the permanent lining castable layer, the tank wall, the lower part of the working lining is a masonry structure, and the upper part is castable The pouring molding structure is coated with an anti-slagging paint layer on the inner wall of the working lining; the depth of the pouring molding structure of the castable is 500-600 mm from the upper edge of the molten iron tank; the thickness of the anti-slagging paint layer is 3-20 mm, and the depth is 600-800 mm from the upper edge of the ladle.

Embodiment 2

[0032] Embodiment two: coating of the present invention consists of:

[0033] al 2 o 3 42%, Na 2 SiO 3 25%, phenolic resin 3%, amorphous carbon 15%, SiO 2 15%, after mixing, add 6% of the total weight of water, then pour the mixed paint into the gunning machine and seal it, and spray on the surface of the designated iron ladle.

Embodiment 3

[0034] Embodiment three: coating of the present invention consists of:

[0035] al 2 o 3 20%, Na 2 SiO 3 25%, phenolic resin 5%, amorphous carbon 25%, SiO 2 25%, pour the paint into the mixer after mixing, first dry stir for 1-5 minutes, then add 8% of the total weight of water, add water and then stir for 5-10 minutes; use mud board and shovel to spread the paint evenly Apply it on the wall of the package with a thickness of 1-2cm. The surface of the coating layer is smooth. It will dry naturally for about 48 hours after application, and then bake it. It can be used after baking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com