Manil putor automatic silicon-wafer grabbing system and method

A technology of manipulators and silicon wafers, applied in the direction of manipulators, conveyor objects, furnaces, etc., can solve problems such as damage, mass production loss, broken, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

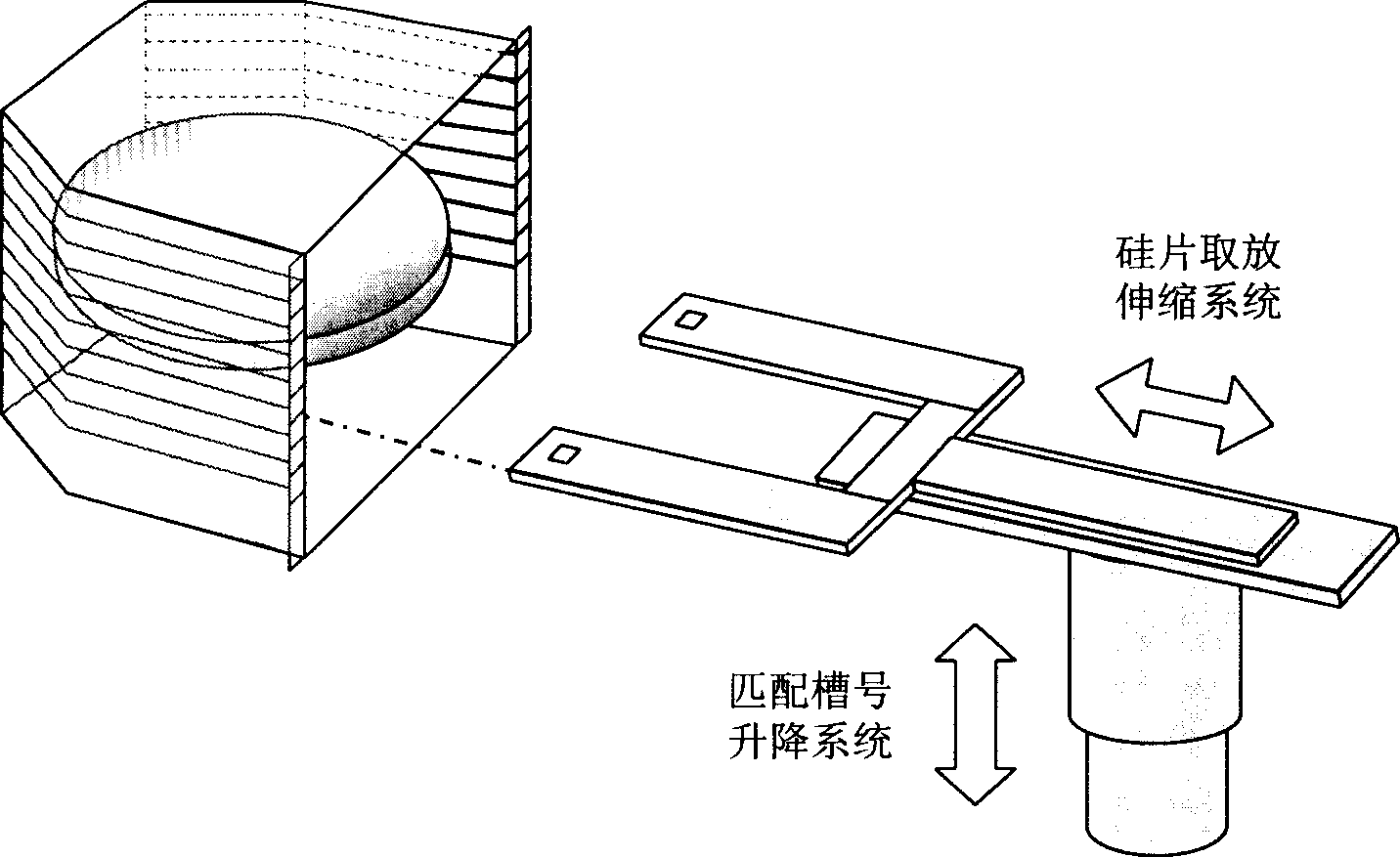

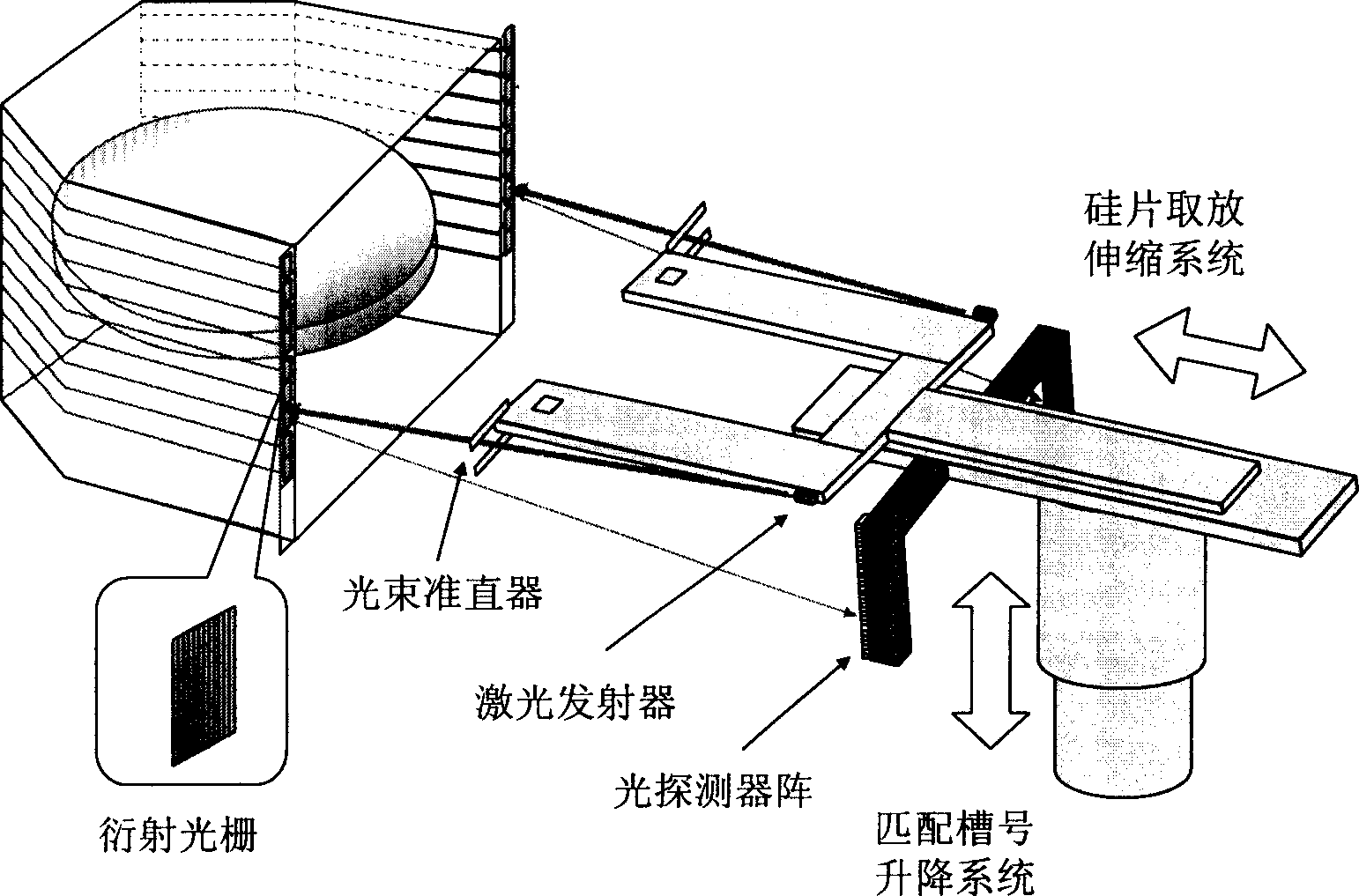

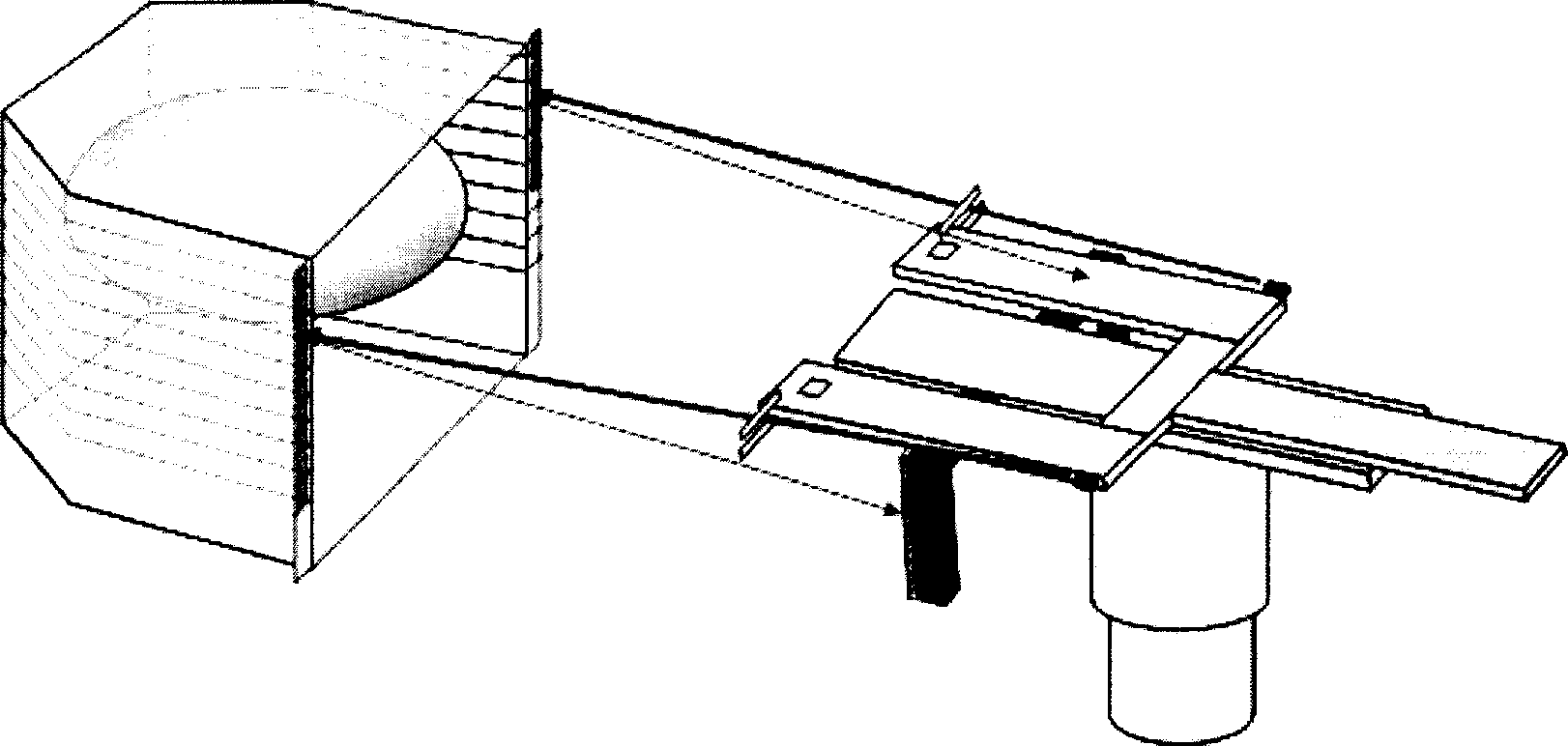

[0017] Such as figure 2 As shown in the present invention, a manipulator automatic silicon wafer pick-and-place system includes a silicon wafer box and a manipulator, and a light emitter is respectively installed on both sides of the rear end of the manipulator carrying the silicon wafer, and the light emitter can be a separate The laser can also be the light output end of the centralized laser projection system distributed and transmitted through the optical fiber. A collimation device corresponding to the light emitter is installed on both sides of the front end of the manipulator carrying the silicon wafer. The collimation device is a collimation hole or a collimation slit. Light can pass through the collimation device. An identification mark is pasted on each groove side of the silicon wafer box, and the identification mark is a diffraction grating array with different codes, or an array of reflection mirrors with different inclination angles. The contents of the identi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com