Air filter

A technology of air filter and filter element, which is applied in the direction of fuel air filter, membrane filter, dispersed particle filter, etc., and can solve the problem of difficult replacement of filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

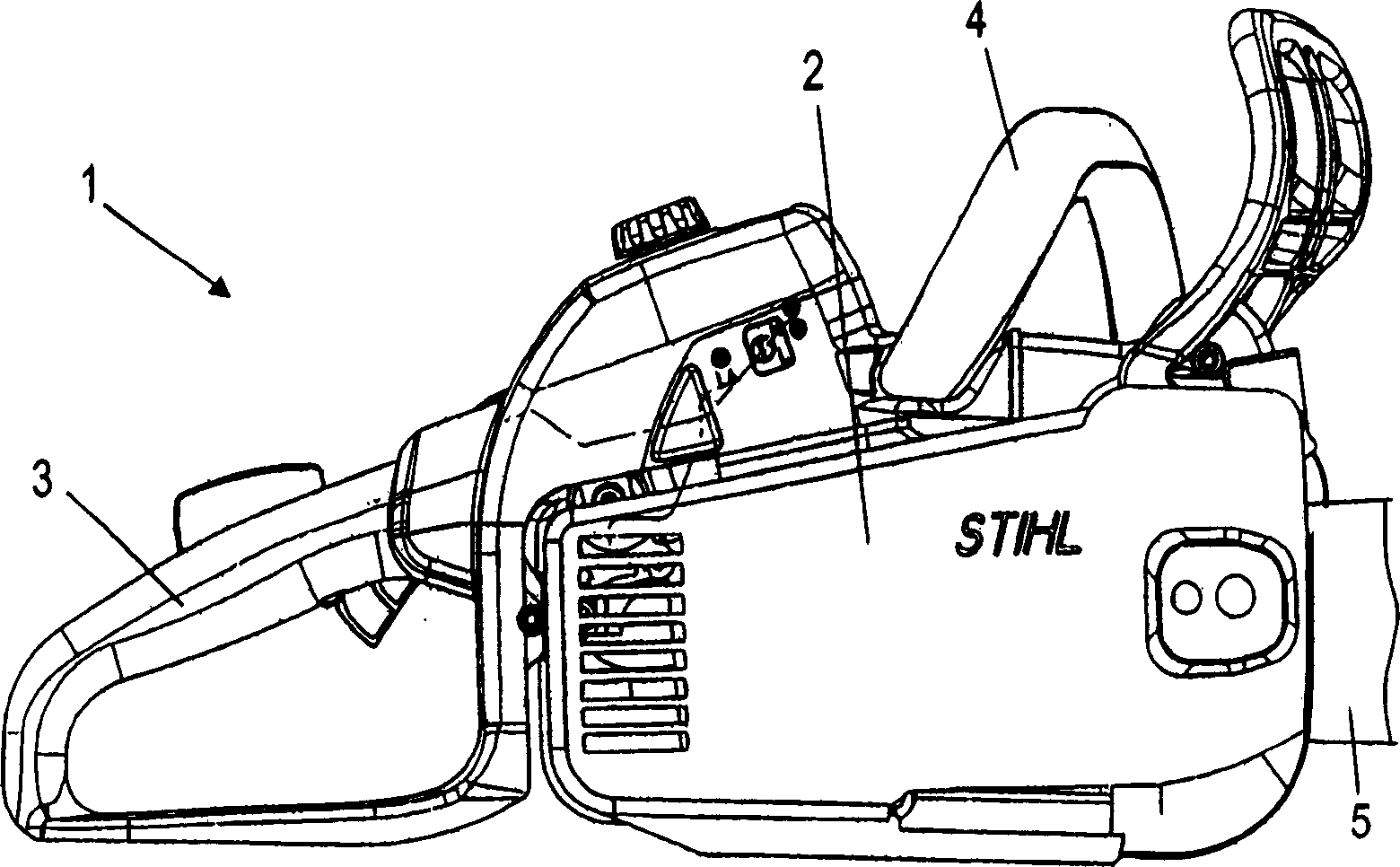

[0021] figure 1 A side view of a hand-held power tool, ie a power saw 1 is shown. The power saw 1 has a housing 2 with a rear handle 3 and a handle tube 4 for guiding the power saw 1 . Be provided with a guide rail 5 on the shell 2 that is positioned at the opposite side of rear handle 3, a guide rail 5 is arranged on figure 1 The saw chain, not shown, circulates around this guide rail. For driving the saw chain, the power saw 1 has an internal combustion engine housed in the housing 2 . Internal combustion engines draw combustion air from the surrounding environment through an air filter.

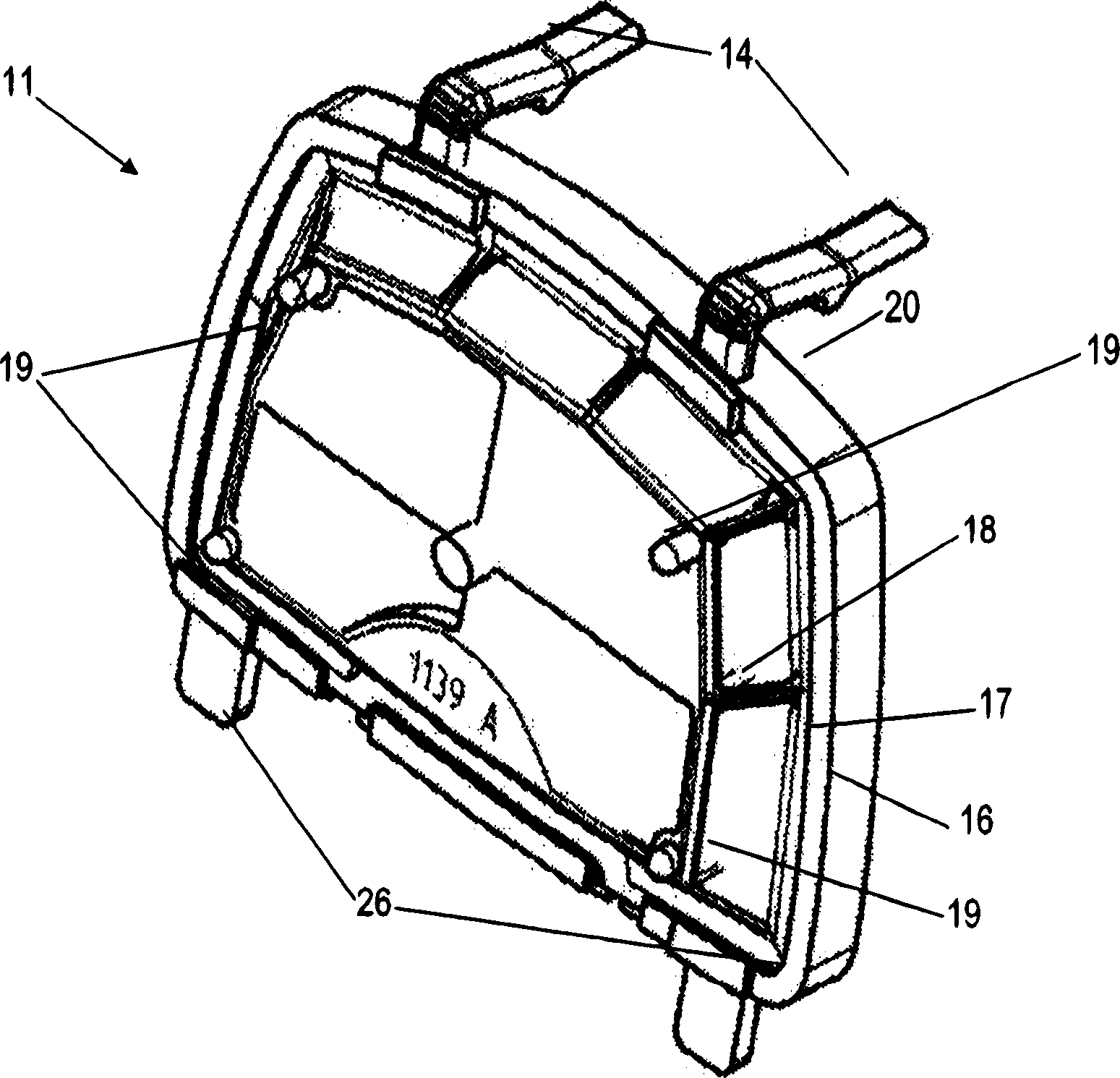

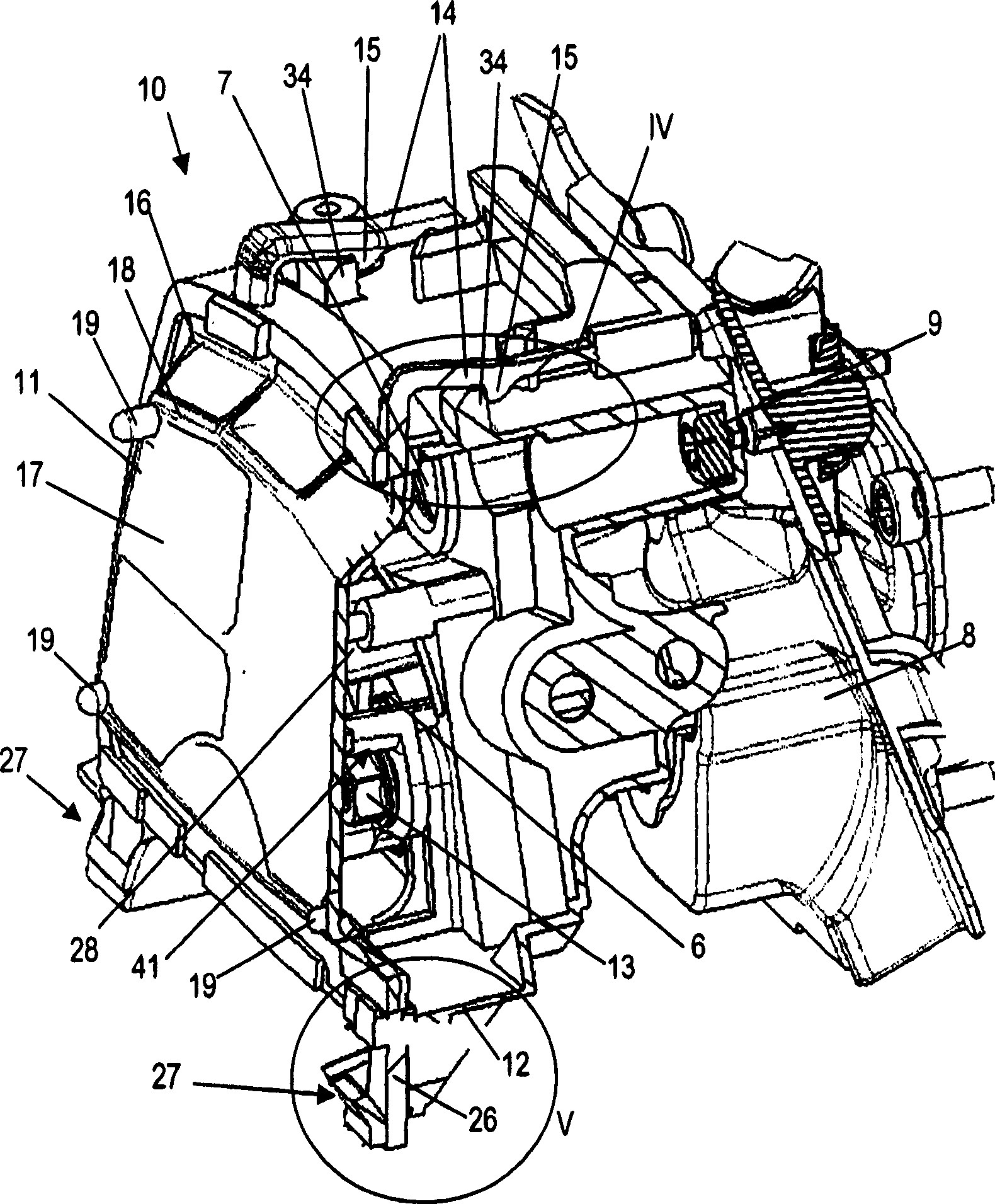

[0022] figure 2 A perspective view of the filter element 11 of the air filter of the power saw 1 is shown. The filter element 11 has a frame 16 with a surrounding edge on which the seal 20 is arranged. The frame 16 has a grid 18 on which the flat filter material 17 of the filter element 11 is held. Four protruding pegs 19 are provided on the grid 18 and serve as protection for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com