Light-guiding plate and back-light module group using same and liquid-crystal display

A technology of backlight module and light guide plate, applied in the field of light guide plate, can solve the problems of picture chromaticity shift, yellowish chromaticity of emitted light, affecting the optical quality of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

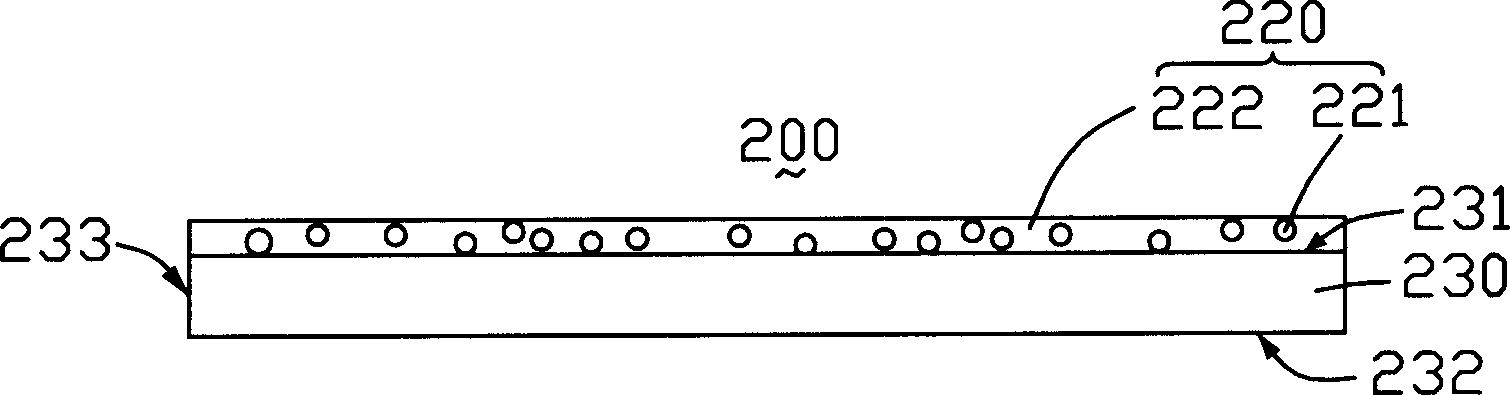

[0017] see figure 2 , is a structural schematic diagram of the first embodiment of the light guide plate of the present invention. The light guide plate 200 includes a base 230, the base 230 has a light exit surface 231, a light entrance surface 233 and a bottom surface 232, the light exit surface 231 is opposite to the bottom surface 232, the light entrance surface 233 is connected to the light exit surface 231 and the bottom surface 232 Adjacent setting. A light-permeable ink layer 220 is formed on the light-emitting surface 231 of the light guide plate.

[0018] The ink layer 220 is formed by screen printing, and its thickness can range from one micron to one hundred microns. The ink layer 220 includes ink 222 and color deviation particles 221 . The ink 222 is a translucent resin. The color shift particles 221 are blue pigment particles or other small molecular dye particles, which are used to absorb a small amount of red light and green light to realize the control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com