Photosensitive thermosetting resin composition, and photosensitive cover lay and flexible printed wiring board using the composition

A solid resin and composition technology, applied in printed circuit, printed circuit manufacturing, optics, etc., can solve problems such as difficult handling, insufficient flexibility, etc., and achieve adhesion retention, long storage period, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18 and comparative example 1~10

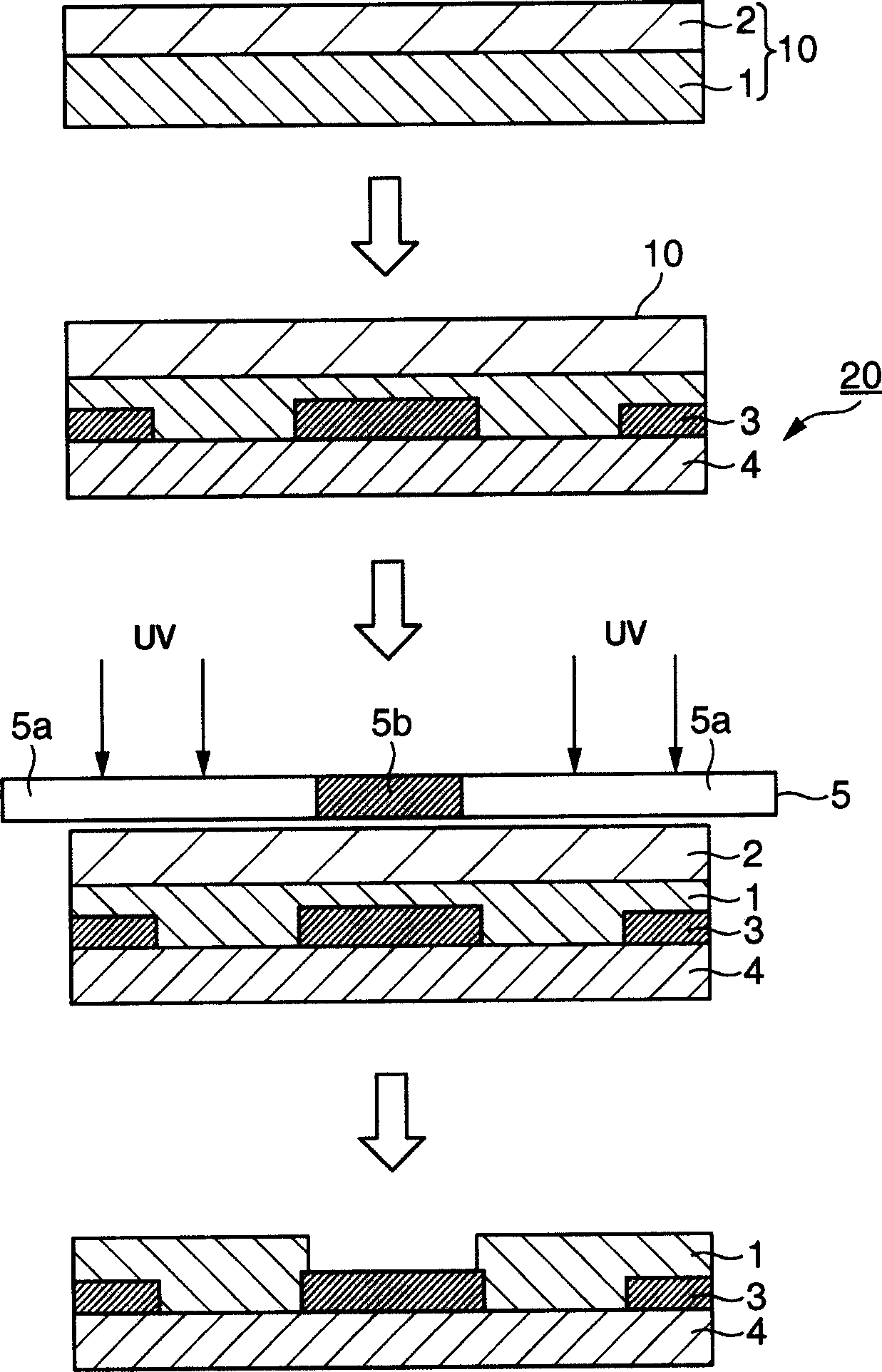

[0100] A photosensitive thermosetting resin composition containing each component in the mixing ratio shown in Table 1 and Table 2 (the unit of the composition amount is parts by weight) was prepared. Then, a photosensitive cover layer provided with a release film is produced on at least one side of a sheet formed by molding the photosensitive thermosetting resin composition into a sheet shape.

[0101] 1) Solder heat resistance test method

[0102] Laminate the photosensitive cover layer (thickness: 25-50 μm) on the copper foil board, carry out UV irradiation, development, heat curing. Then, the soldering fluids were respectively set at 160°C and 288°C, and soaked for 30 seconds respectively. The presence or absence of peeling, swelling, etc. was observed visually. And, the solder heat resistance was evaluated according to the following criteria.

[0103] ◎Immersed at 288℃×30sec, no peeling or swelling

[0104] ○Immersed at 260°C×30sec, there is no peeling and swelling; s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com