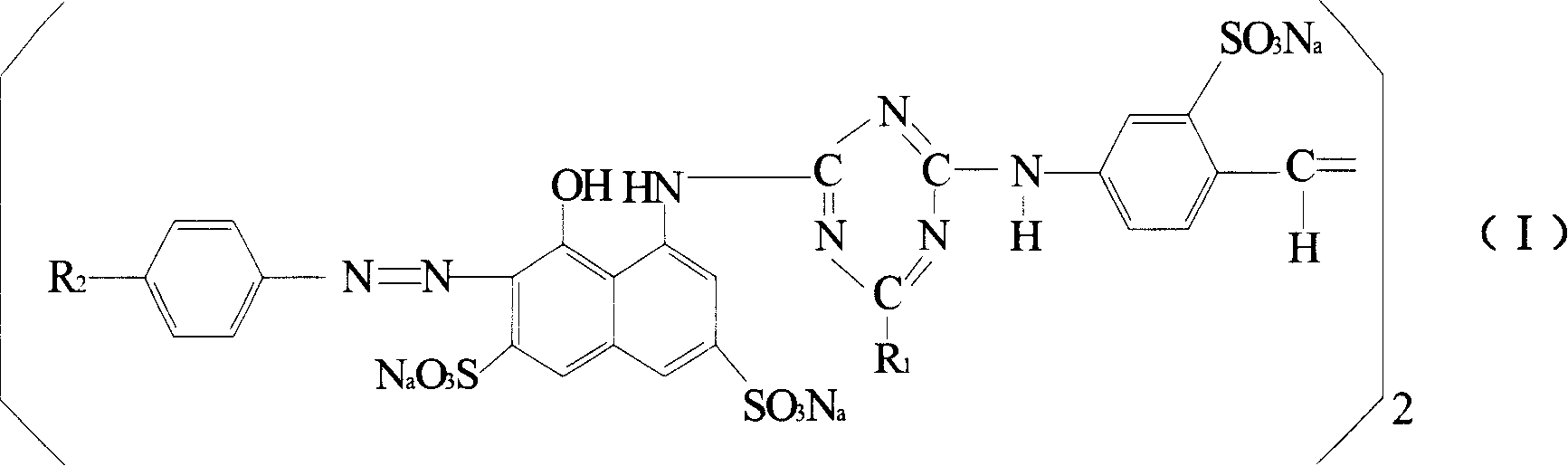

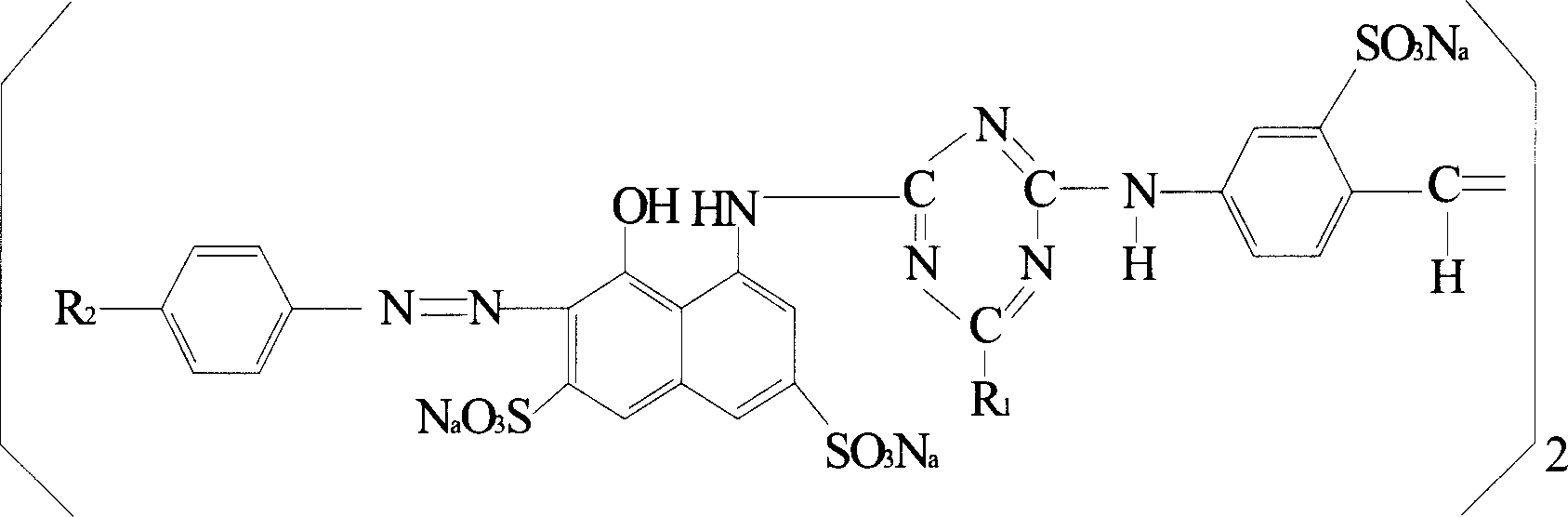

Directly blending rose dye and its preparing process

A preparation process and technology of red dye, applied in the field of direct blended rose red dye and preparation process thereof, can solve problems such as lack of chromatography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

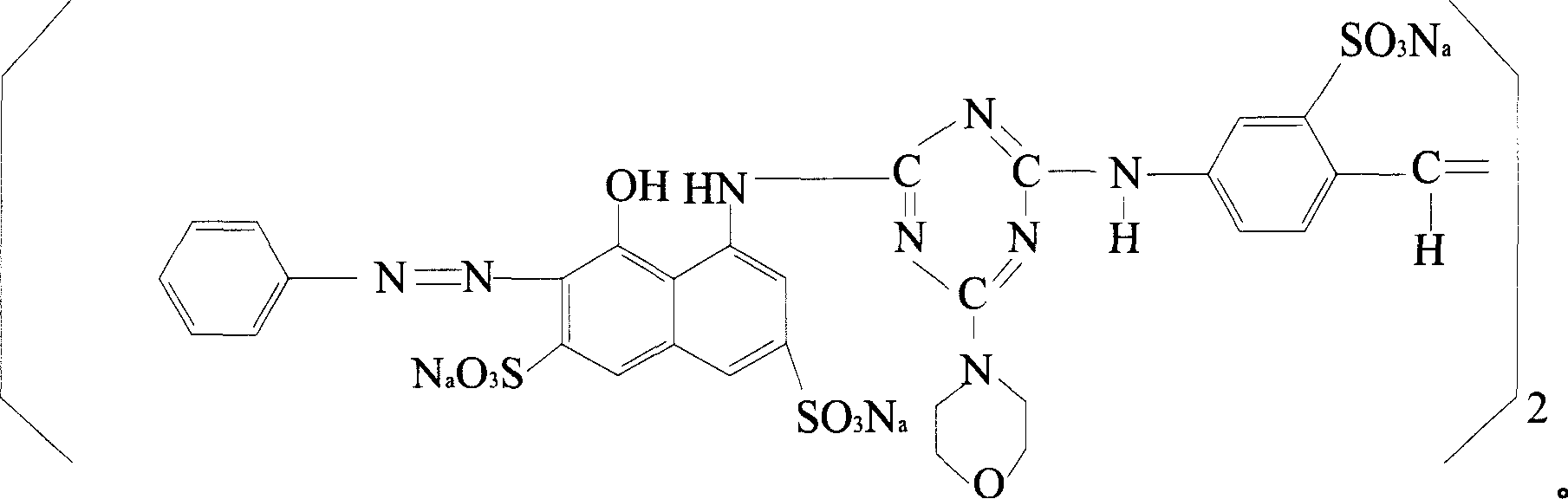

Examples

Embodiment 1

[0031] The preparation technology of direct blending rose red D-FR dyestuff comprises the following steps:

[0032] (1) The first condensation reaction: Add 0.1mol of cyanuric chloride to 3.4mol of water and 80g of crushed ice, stir and beat for 20 minutes, control the temperature at 0-2 degrees Celsius, and then add it dropwise within 1.5 hours 1-amino-8 naphthol-3,6 disulfonic acid solution, described 1-amino-8 naphthol-3,6 disulfonic acid solution is 1-amino-8 naphthol-3,6 by 0.098mol Disulfonic acid, join in the water of 12mol, adjust temperature and be 25-30 degree centigrade, add concentration and be 30% sodium hydroxide solution and adjust pH value to be 6-6.5, temperature remains on 0-5 degree centigrade, makes 1-amino-8 naphthalene Phenol-3, the solution prepared when all 6 disulfonic acids are fully dissolved, then use a 15% sodium carbonate solution to maintain the pH value of the reaction at 3-3.2, continue the reaction for 3 hours, and use indicator p-dimethylamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com