Electromagnetic range capable of automatic control temperature

A technology of electromagnetic cooker and magnetic steel, applied in the field of electromagnetic cooker, can solve the problems of inconvenience, poor thermal conductivity, restricting the development of electromagnetic cooker, etc., and achieve the effects of improving the degree of automation, overcoming slow response, and accurate and timely detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

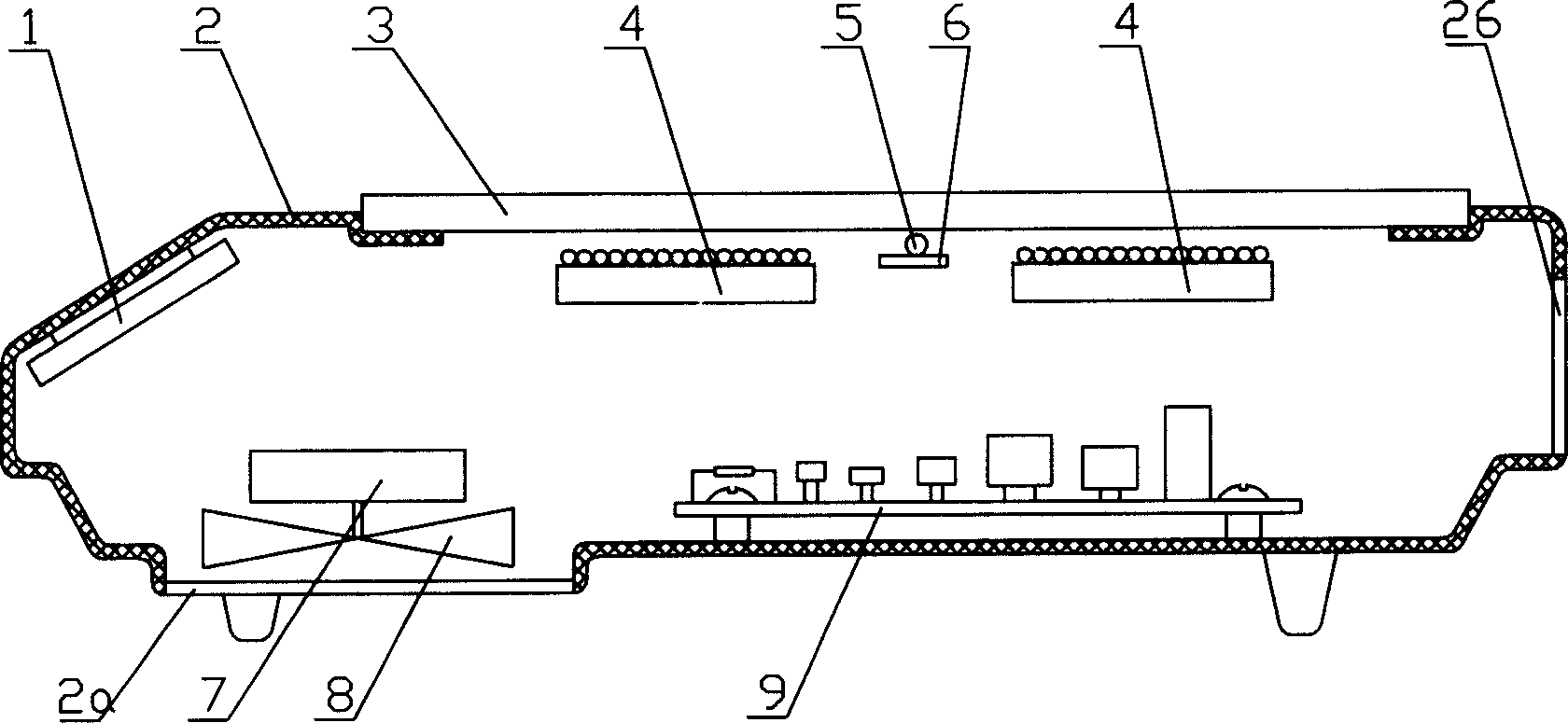

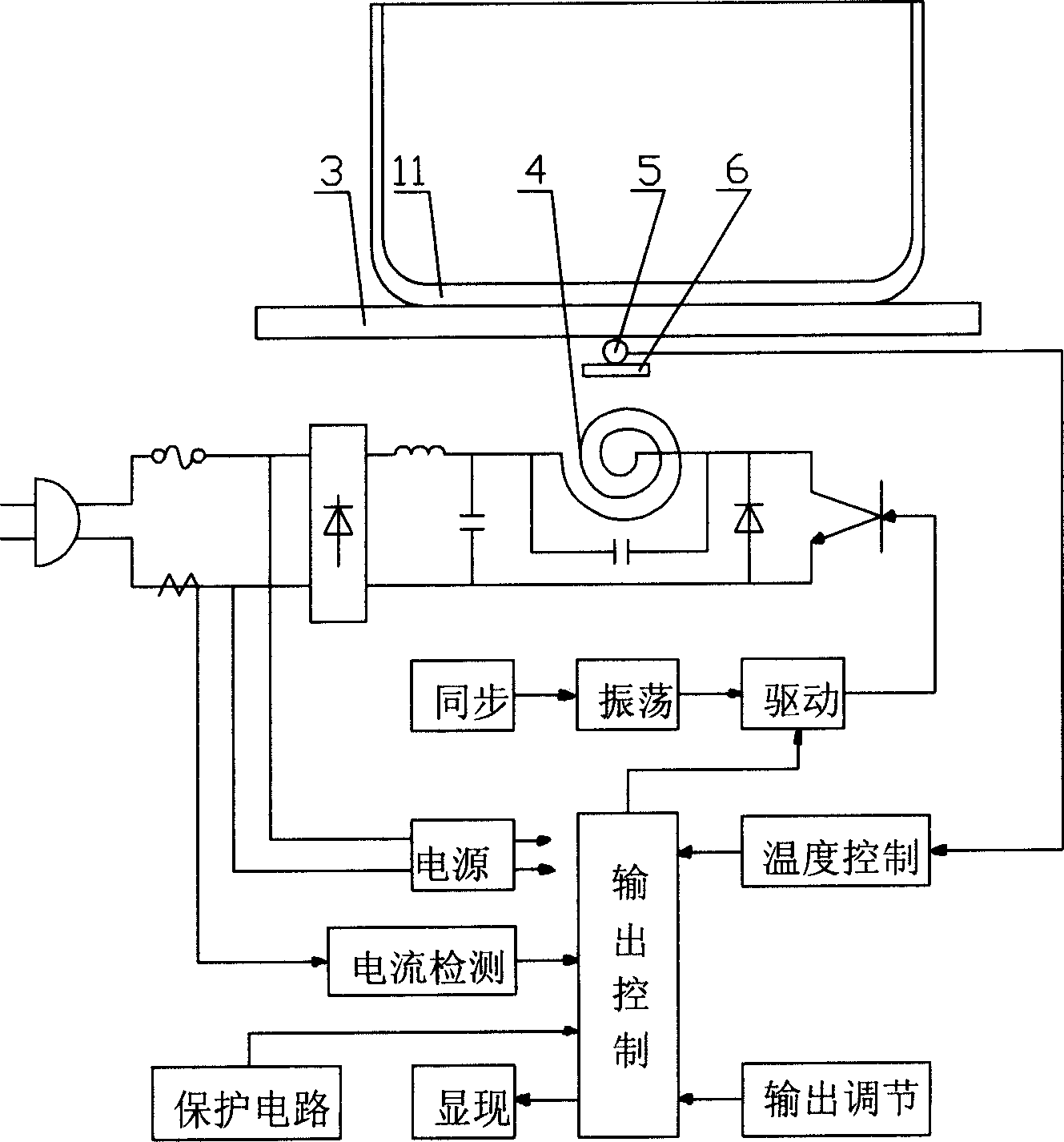

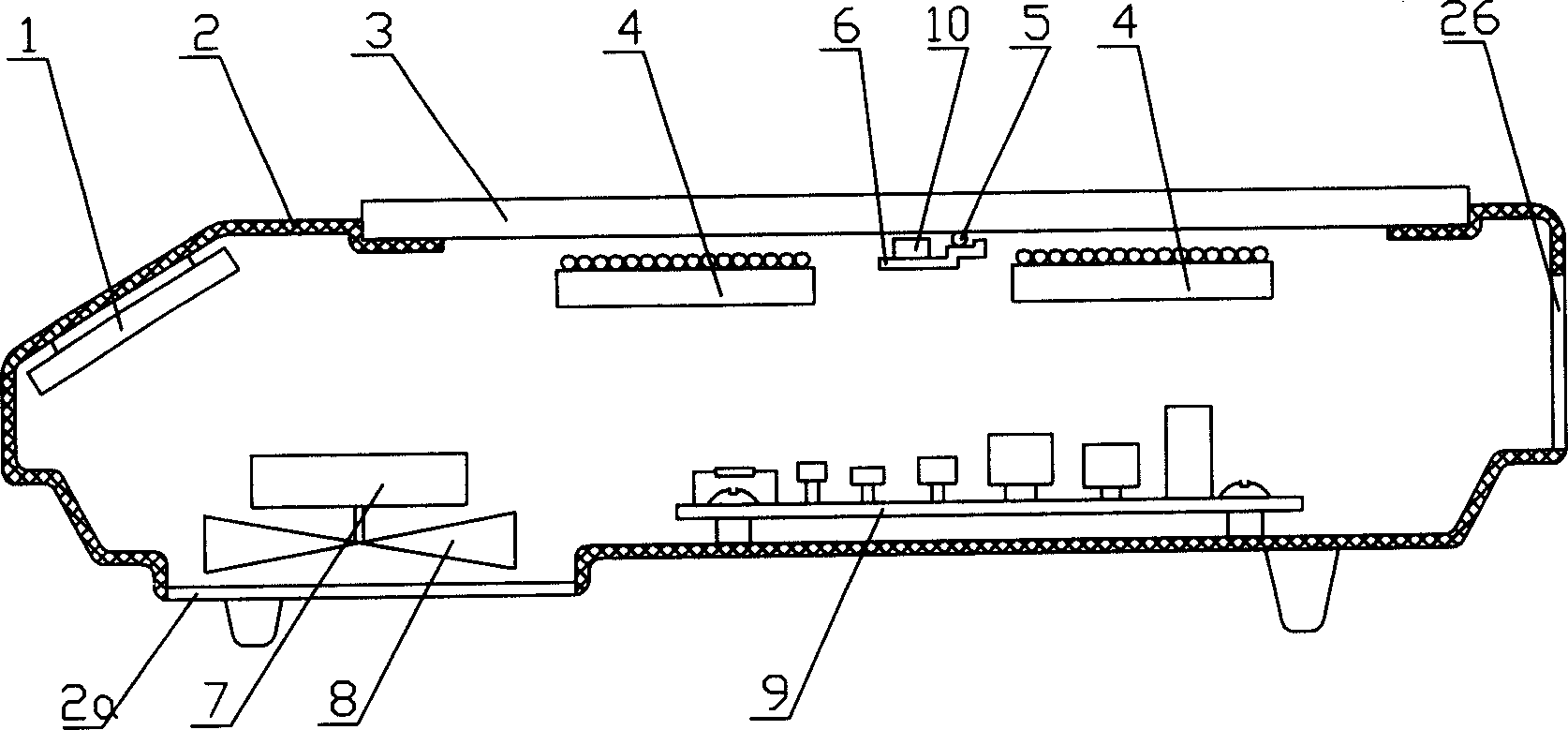

[0022] like Figure 3 ~ Figure 5 The electromagnetic cooker with automatic temperature control shown is one of the embodiments of the present invention, including an electromagnetic cooker shell 2, a platen 3, a heating coil 4, a control board, a bracket 6, a heat dissipation mechanism and a temperature sensing device, wherein the heat dissipation mechanism includes a fan Motor 7, fan 8, air inlet 2a and air outlet 2b, temperature sensing device comprises thermistor 5 and magnetosensitive sensor 10, is all positioned at the central part of annular heating coil 4 below platen 3, is fixed by support 6, described The bracket 6 is a ladder-shaped frame with a longitudinal section, the thermistor 5 is fixed on the higher frame, and the magnetic sensor 10 is fixed on the lower frame. The sensor adopts a coil 101. The top of plate 3 is placed with matching design electromagnetic cooker 11, and the center of this electromagnetic cooker 11 bottom outer surface is fixed with a disc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com