Preparation method of super large pore polymer microsphere and its product

A technology of ultra-large pores and polymers, which is applied in the interdisciplinary fields of polymer materials and biochemical engineering, and can solve problems such as unsuitable scale-up, cumbersome preparation process, and complicated formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

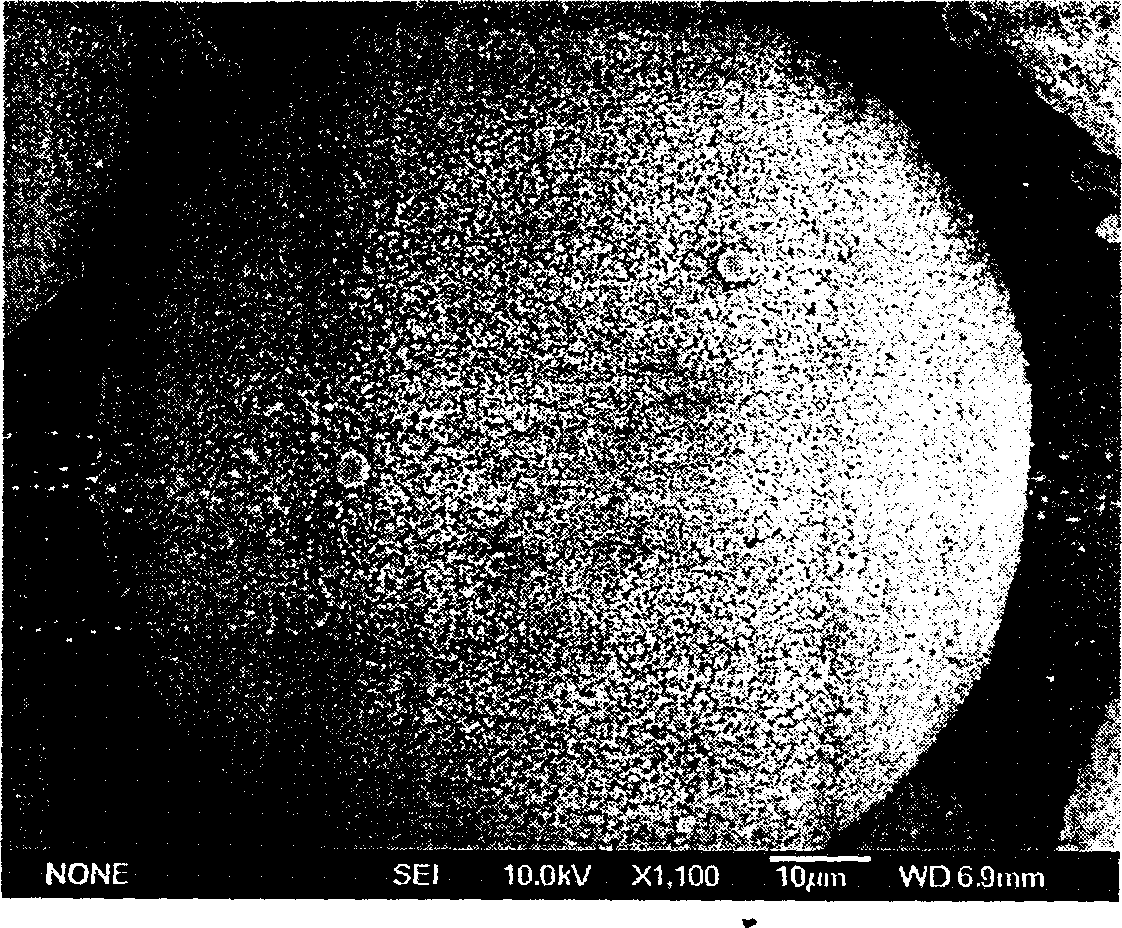

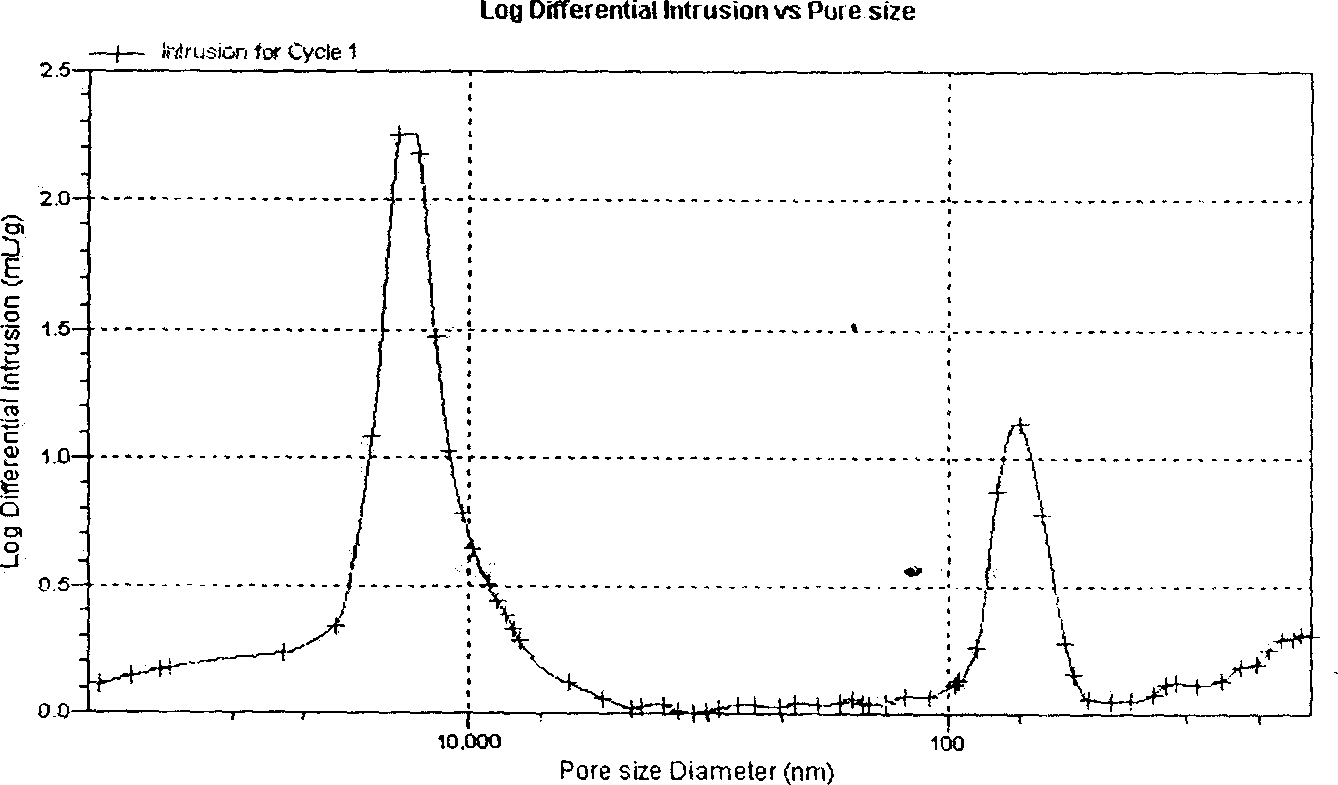

Embodiment 1

[0039] Accurately weigh 37.5g of styrene and 12.5g of divinylbenzene into a 100mL beaker, add 2.0g of benzoyl peroxide, 25.0g of hexadecane and 35.0g of span80, and stir until the initiator is completely dissolved. Dissolve 1.0g of PVA in 500mL of distilled water to form the water phase. The oil phase was added to the water phase, stirred at a speed of 200 rpm, nitrogen gas was passed for 1 h, and polymerized at 75° C. for 24 h. After the reaction is finished, filter, wash the product several times with distilled water and ethanol, wash the diluent, surfactant and other components, and dry to obtain the product. The electron micrographs of the obtained microspheres are as follows: figure 1 shown. Characterize the microsphere structure and measure: the specific surface area is 126.9m 2 / g, the porosity is 65.5%, the density is 0.40g / mL, and it has two kinds of pore distribution, one is super large pores of 1-60μm, and the other is small pores of 30-100nm, such as figure 2 ...

Embodiment 2

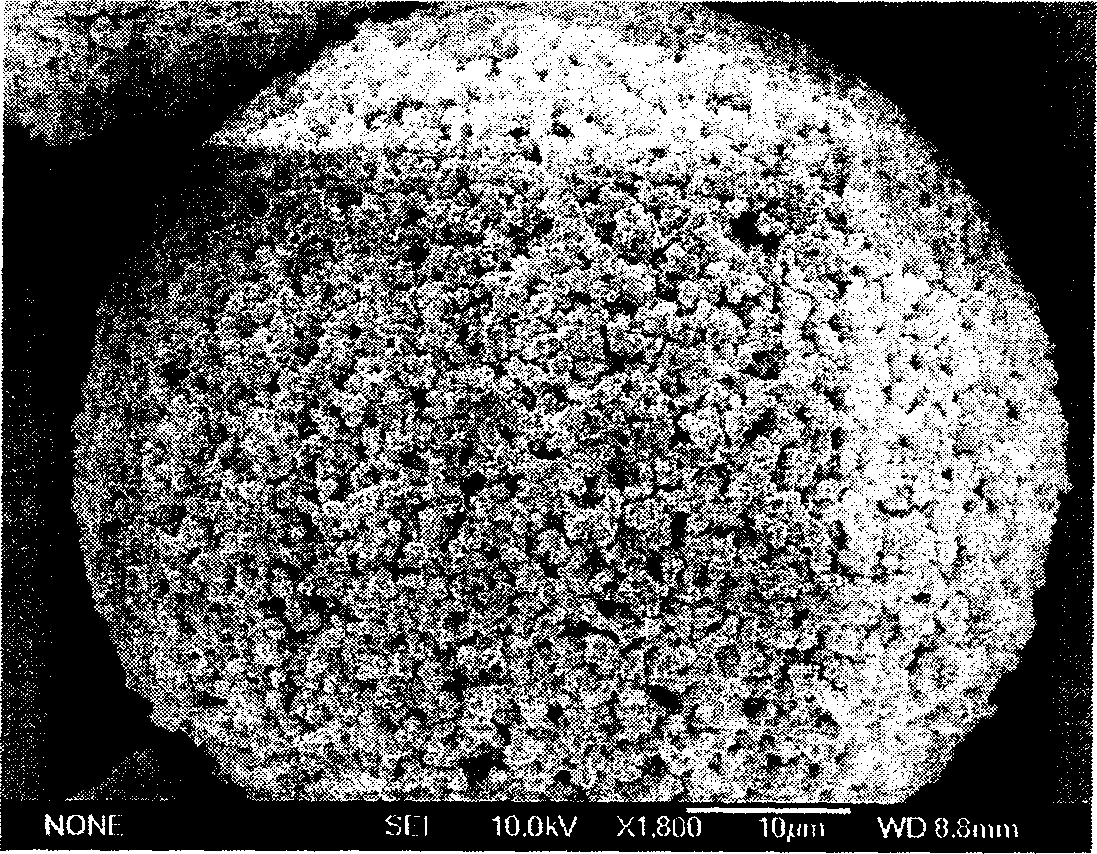

[0041] Accurately weigh 35.0g of styrene and 15.0g of divinylbenzene into a 100mL beaker, add 2.0g of benzoyl peroxide, 35.0g of hexadecane and 45.0g of span80, and stir until the initiator is completely dissolved. Dissolve 1.0g of PVA in 500mL of distilled water to form the water phase. The oil phase was added to the water phase, stirred at a speed of 200 rpm, nitrogen gas was passed for 1 h, and polymerized at 75° C. for 24 h. After the reaction is finished, filter, wash the product several times with distilled water and ethanol, wash the diluent, surfactant and other components, and dry to obtain the product. The electron micrographs of the obtained microspheres are as follows: image 3 shown. Characterize the microsphere structure and measure: the specific surface area is 203.8m 2 / g, the porosity is 83.6%, and the density is 0.31g / mL. It mainly has two kinds of pore distribution, one is super large pores of 1-60μm, and the other is small pores of 200-800nm, such as F...

Embodiment 3

[0043] Accurately weigh 37.5g of styrene and 12.5g of divinylbenzene into a 100mL beaker, add 1.5g of azobisisobutyronitrile, 25.0g of hexadecane and 35.0g of span80, and stir until the initiator is completely dissolved. Dissolve 1.0g of PVA in 500mL of distilled water to form the water phase. The oil phase was added to the water phase, stirred at a speed of 200 rpm, nitrogen gas was passed for 1 h, and polymerized at 75° C. for 24 h. After the reaction is finished, filter, wash the product several times with distilled water and ethanol, wash the diluent, surfactant and other components, and dry to obtain the product. The electron micrographs of the obtained microspheres are as follows: Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com