Mineral oils with improved conductivity and cold flowability

A mineral oil, conductivity technology, used in the petroleum industry, lubricating compositions, fuels, etc., to solve problems such as freezing conveyor lines and filter clogging, increased corrosion problems, etc.

Inactive Publication Date: 2007-01-31

CLARIANT PROD DEUT GMBH

View PDF13 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But for these oils, the subsequent addition of water only leads to the dispersion of undissolved water in the oil, which does not contribute to the improvement of conductivity, but instead leads to increased corrosion problems and, at low temperatures, the risk of freezing and Resulting clogging of delivery lines and filters

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0133] Table 1: Characterization of Test Oils:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

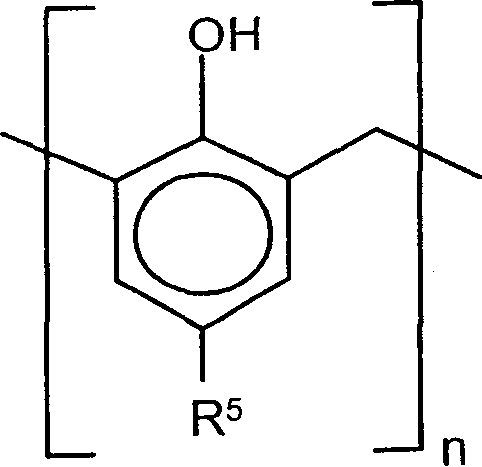

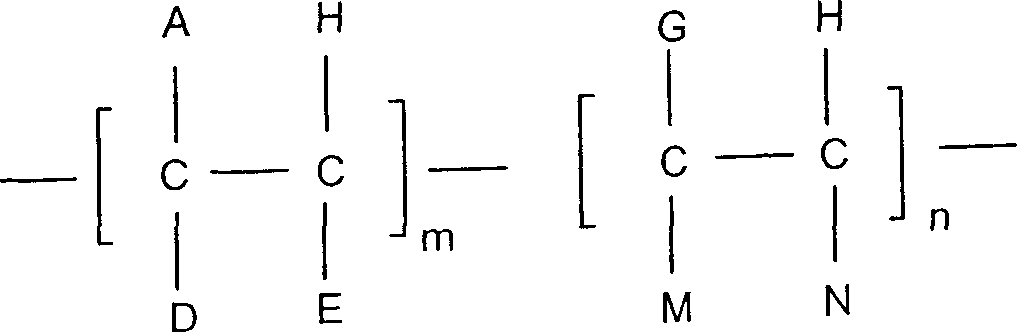

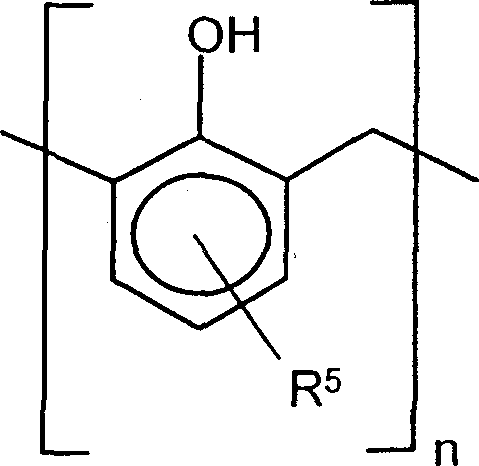

A mineral oil distillate having a water content of less than 150 ppm and a conductivity of at least 50 pS / m, comprises 0.1-200 ppm at least one alkylphenolaldehyde resin and 0.1-200 ppm at least one nitrogen-containing polymer.

Description

technical field [0001] The present invention relates to the use of alkylphenol-aldehyde resins and nitrogen-containing polymers for improving the electrical conductivity of low water mineral oil fractions, and to mineral oil fractions to which additives are added. Background technique [0002] In the course of increasingly stringent environmental legislation, the content of sulfur-containing compounds and aromatic hydrocarbons in mineral oil fractions must be reduced even further. But other polar and aromatic compounds are also removed at the same time in the refinery process used to produce on-spec mineral oil quality. Here, too, the absorption capacity of oil for water often decreases. As a side effect, the electrical conductivity of these mineral oil fractions is thereby greatly reduced. Consequently, static charges generated in the distribution chain and in the equipment of the consumer cannot be balanced, as especially at high flow rates, eg during circulation pumping...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M145/20C10M149/00C10N20/00

CPCC10L1/2364C10L10/14C10L1/1981C10L1/2366C10L1/2383C10L1/146C10L1/236C10M101/00C10L2230/20

Inventor M·克鲁尔W·赖曼

Owner CLARIANT PROD DEUT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com