Device diagnosis device, freezing cycle device, fluid circuit diagnosis method, device monitoring system, and freezing cycle monitoring system

A diagnostic device and circulation device technology, which is applied in the fields of equipment diagnostic device, refrigeration cycle device, fluid circuit diagnosis, equipment monitoring system, and refrigeration cycle monitoring system, and can solve problems such as high price, inability to become accurate, and inability to consider actual machine false detection, etc. , to achieve the effect of reliable monitoring and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

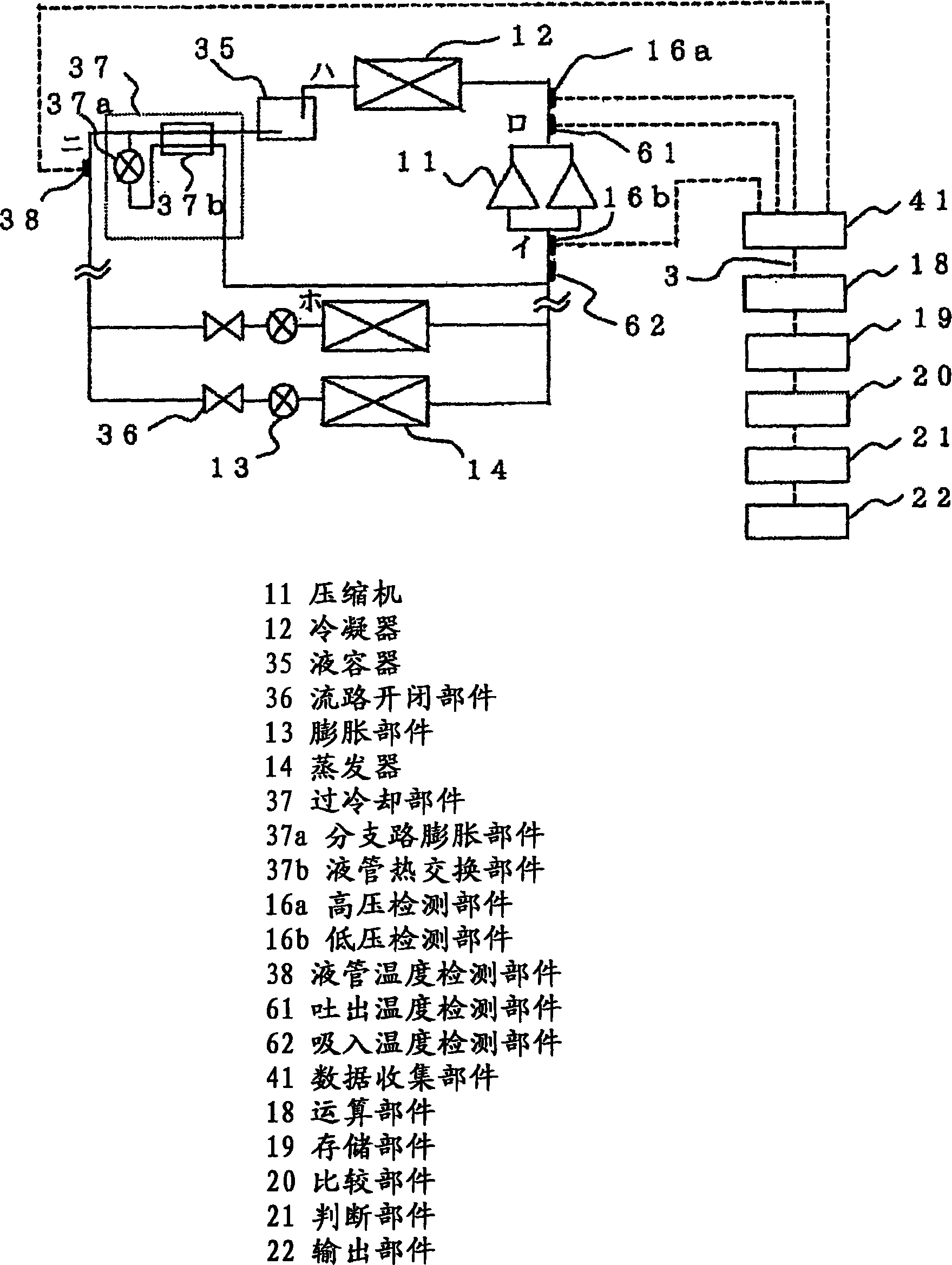

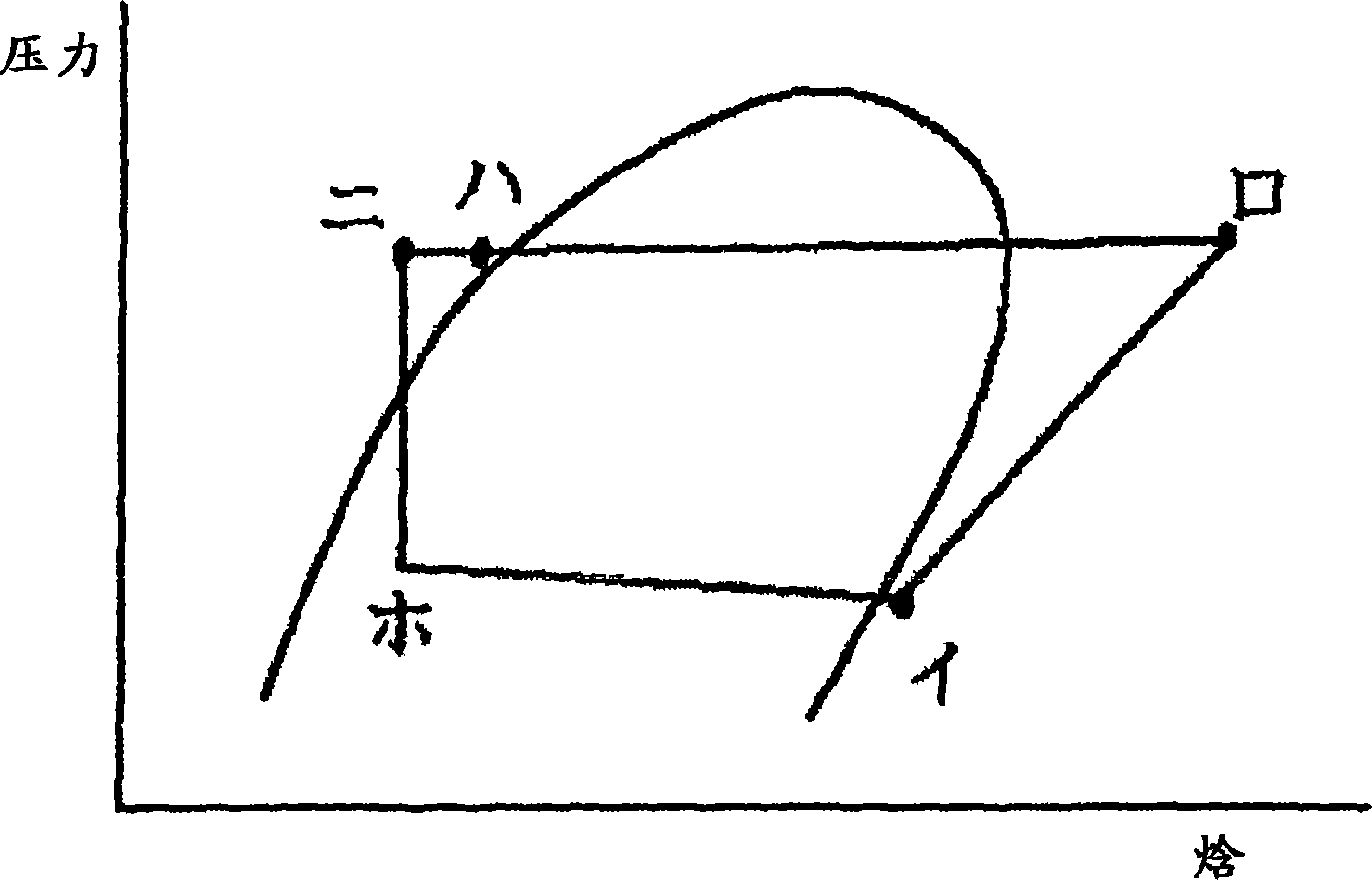

[0052] use Figure 1 to Figure 8 The configuration of Embodiment 1 of the present invention will be described. figure 1 It is an overall conceptual diagram of the present invention. 1 is a refrigeration cycle device such as a refrigerator or an air conditioner. Outputs such as warning lamps and substrates and microcomputers of devices for sending and receiving data to and from the outside, 3 are components for communicating with the outside such as telephone lines, local area network lines, and wireless, and 4 is for remote monitoring of the refrigeration cycle device 1 and The remote monitoring room for centralized management such as control, 5 is arranged in the remote monitoring room 4, and has the remote monitoring part that is used for displaying and computing functions of data transmission and reception with the refrigeration cycle device 1, that is, a computer, and 6 is set in the remote monitoring room 4. A display device such as a liquid crystal display in the refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com