Speaker, speaker-use diaphragm, dust cap, production methods and production devices for them

A manufacturing method and vibration plate technology, applied in the direction of diaphragm structure, non-planar diaphragm/paper cone, etc., can solve the problems that the pulp cannot be uniformly dispersed, and the characteristics and sound quality cannot be achieved, so as to improve productivity and dimensional stability, The effect of excellent appearance and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0082] Hereinafter, the speaker diaphragm of the present invention will be described using the first embodiment.

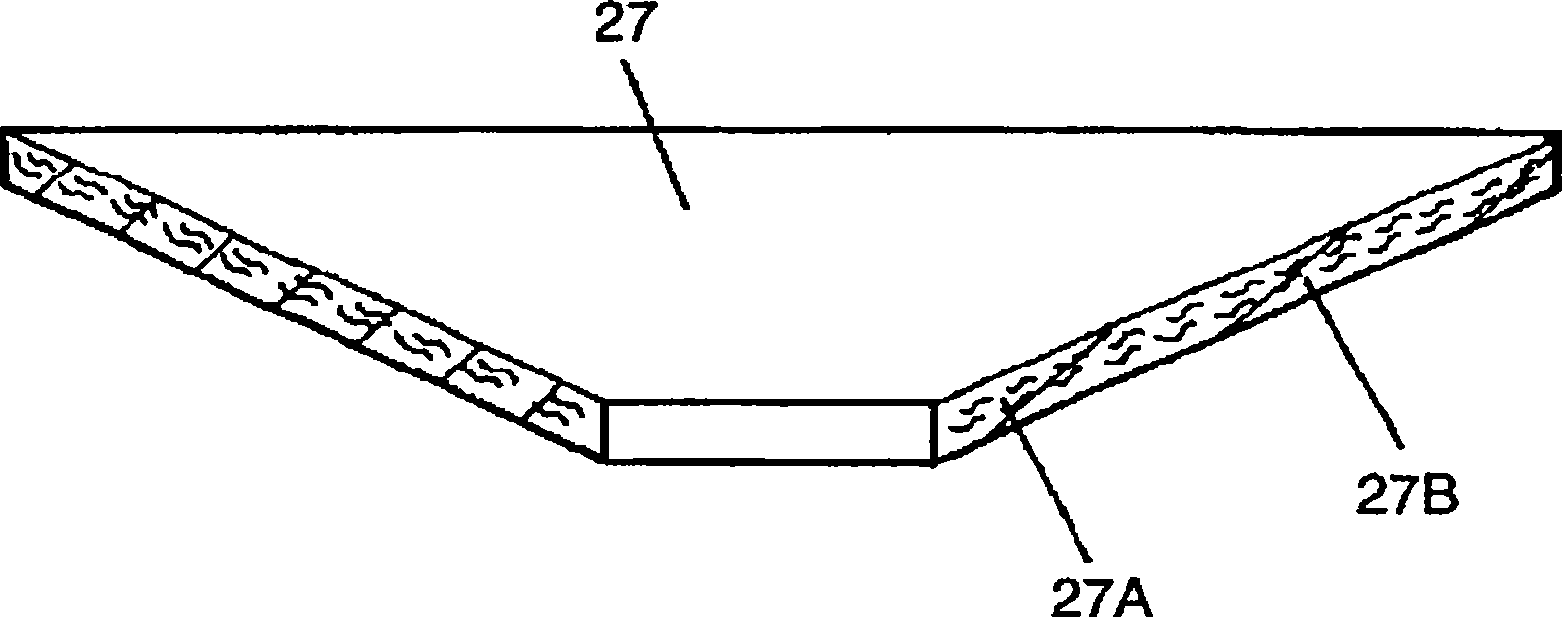

[0083] figure 1 with figure 2 The vibration plate of one embodiment of the present invention is shown.

[0084] The vibration plate 27 is manufactured by injection molding a molding material mixed with a resin material 27A and pulp 27B. The resin material 27A of the vibration plate 27 uses a crystalline or non-crystalline olefin resin.

[0085] Good moldability can be achieved by using olefin resin. In addition, by distinguishing the use of crystalline and non-crystalline resin materials according to their uses, it is possible to obtain the best physical properties as a resin material.

[0086] The case where polypropylene is used as the resin material 27A will be described below. Polypropylene is generally easy to obtain and easy to injection mold. However, the present invention is not limited to polypropylene, and various resin materials can be used separately ac...

no. 2 approach

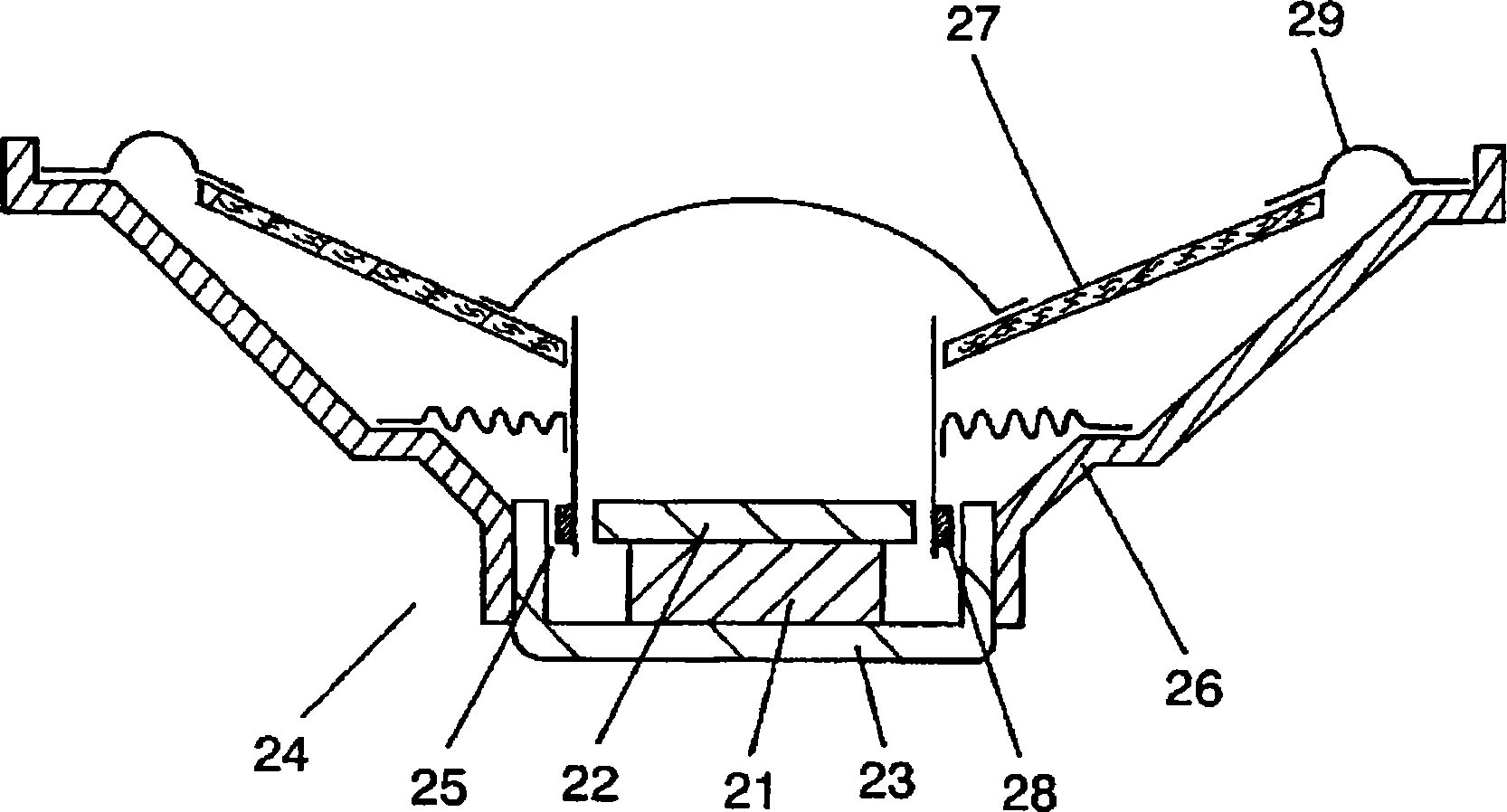

[0107] image 3 A cross-sectional view of a speaker according to an embodiment of the present invention is shown. Such as image 3 As shown, the magnetized magnet 21 is sandwiched between the upper plate 22 and the yoke 23 to form an internal magnetic type magnetic circuit 24.

[0108] The yoke 23 of the magnetic circuit 24 is mounted on the frame 26. The outer periphery of the diaphragm 27 described in the first embodiment is joined to the edge portion of the frame 26 by the edge 29. Furthermore, one end of the voice coil 28 is connected to the center portion of the vibration plate 27, and the other end is inserted into the magnetic gap of the above-mentioned magnetic circuit 24.

[0109] In the second embodiment, the speaker having the internal magnetic type magnetic circuit 24 has been described, but the present invention is not limited to this, and can also be applied to a speaker having an external magnetic type magnetic circuit. In addition, it can also be applied to a smal...

no. 3 approach

[0114] Figure 4 An external view of a mini combo system for audio as an electronic device according to an embodiment of the present invention is shown. Such as Figure 4 As shown, the speaker 30 described in the second embodiment of the present invention is assembled into the housing 41 to constitute a speaker system. The audio mini-combination system 44 as an electronic device includes an amplifier 42 as an amplifying device of an electric signal input to the speaker 30, and a player 43 that outputs a source signal input to the amplifier 42.

[0115] By using the diaphragm of the present invention to manufacture a speaker system, an electronic device can be realized that can perform high-precision feature creation and sound creation that effectively combine the characteristics of both the paper diaphragm and the resin diaphragm that could not be achieved in the past. , And design.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com