Preparation method of functional beef tallow

A functional, butter technology, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of loss of nutrients, high peroxide value of butter products, etc., to reduce peroxide value, reduce bacterial pollution, prevent The effect of over-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

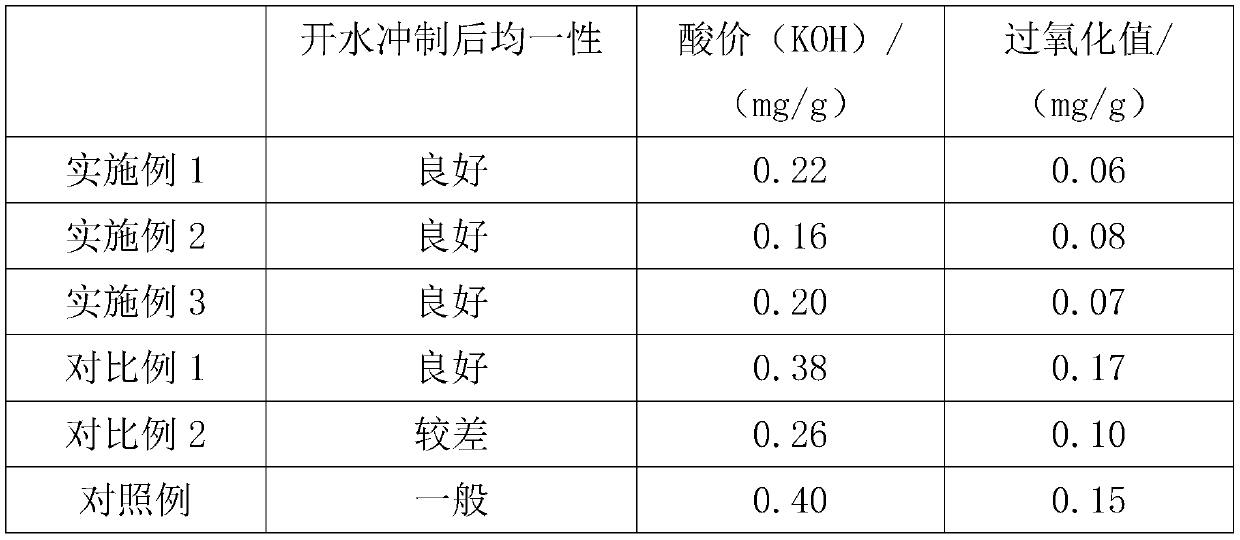

Examples

Embodiment 1

[0017] (1) Preparation of tea extract: select 3 parts of fresh tea leaves as raw materials, chopped or smashed, add 3% ginger flakes powder of fresh tea mass, stir thoroughly, and let stand; then steam the obtained product in water, The temperature of the water-isolated cooking is 70℃, and the water-isolated cooking for 10 minutes; then microwave heating, microwave heating for 10 minutes, and after cooling to 50℃, add cellulase with 0.5% mass fraction of the solution. After enzymatic hydrolysis at constant temperature for 3 hours, it will be quenched at 90℃. Enzyme, solid-liquid separation to obtain tea extract;

[0018] (2) Prepare starch solution: take 10 parts of amylose and 5 parts of water and heat at 82℃, stir while heating, heat for 20 minutes until it is evenly stirred, then add tea extract and continue stirring until the solution is uniform in color Consistent, get starch solution;

[0019] (3) Preparation of an emulsion: 100 parts of tallow and 0.12 parts of sucrose fatt...

Embodiment 2

[0023] (1) Preparation of tea extract: select 4 parts of fresh tea leaves as raw materials, chopped or smashed, add 5% ginger flakes powder of the quality of fresh tea leaves, stir thoroughly, and let stand; then steam the obtained product in water. The temperature of the water-isolated cooking is 100℃, and the water-isolated cooking for 30 minutes; then microwave heating, microwave heating for 30 minutes, cool to 70℃, add cellulase with 3% solution mass fraction, constant temperature enzymatic hydrolysis for 12h, then kill at 110℃ Enzyme, solid-liquid separation to obtain tea extract;

[0024] (2) Prepare starch solution: Take 10 parts of amylose and 6 parts of water and heat at 85℃, stir while heating, heat for 40 minutes until it is evenly stirred, then add tea extract and continue stirring until the color of the solution is uniform Consistent; get starch solution;

[0025] (3) Preparation of emulsified liquid: mix tallow and sucrose fatty acid ester at 66°C to form an emulsifi...

Embodiment 3

[0029] (1) Preparation of tea extract: select 4 parts of fresh tea leaves as raw materials, chopped or smashed, add 4% ginger flakes powder by mass of fresh tea leaves, stir thoroughly, and let stand; then steam the obtained product in water. The temperature of the water-isolated cooking is 80℃, and the water-isolated cooking for 20 minutes; then microwave heating, microwave heating for 20 minutes, and after cooling to 60℃, add cellulase with 2% mass fraction of the solution. After enzymatic hydrolysis at constant temperature for 5 hours, it will be quenched at 100℃. Enzyme, solid-liquid separation to obtain tea extract;

[0030] (2) Prepare starch solution: Take 10 parts of amylose and 5 parts of water and heat at 83℃, stir while heating, heat for 30 minutes until it is evenly stirred, then add tea extract and continue to stir until the solution is uniform in color Consistent, get starch solution;

[0031] (3) Preparation of emulsified liquid: mix tallow and sucrose fatty acid es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com