Solvent quenching accelerating device online co-operated with gas phase chromatography and method thereof

A technology for accelerating solvent and gas chromatography, applied in measurement devices, ion exchange processing devices, material separation, etc., can solve problems such as low sample utilization rate, inability to apply gas chromatography on-line analysis, etc., to improve detection sensitivity, simplify pretreatment, Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

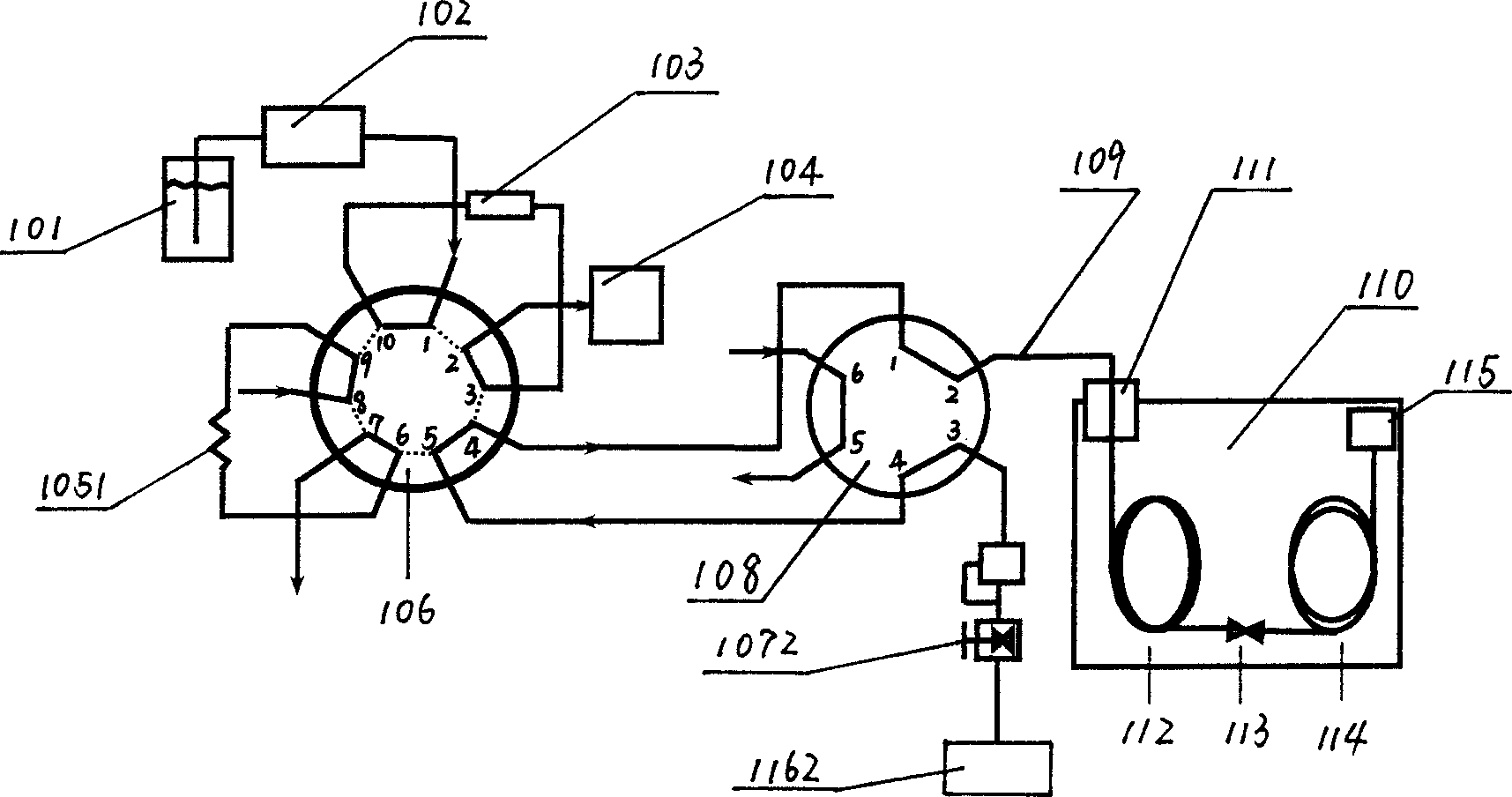

[0034] Such as Figure 1A ~ Figure 1C Shown is a schematic diagram of the entire sampling device for accelerated solvent extraction coupled with gas chromatography. The solvent delivery high-pressure pump 102 is connected to the No. 1 position of the ten-way valve 106. The inlet pipe 201 and the outlet pipe 211 of the extraction tank 2 are respectively connected to the No. 10 and No. 3 positions of the ten-way valve 106 using stainless steel pipes with small inner diameters. The sensor 104 is connected to the No. 2 position of the ten-way valve 106, the two ends of the first metering tube 1051 are respectively connected to the No. 9 and No. 6 positions of the ten-way valve 106, and the No. 8 and No. 7 positions of the ten-way valve 106 They are respectively the inlet and the outlet for injecting the solution into the first measuring tube 1051, and No. 4 and No. 5 positions of the ten-way valve 106 are respectively connected with No. 1 and No. 4 positions of the six-way valve 1...

Embodiment 2

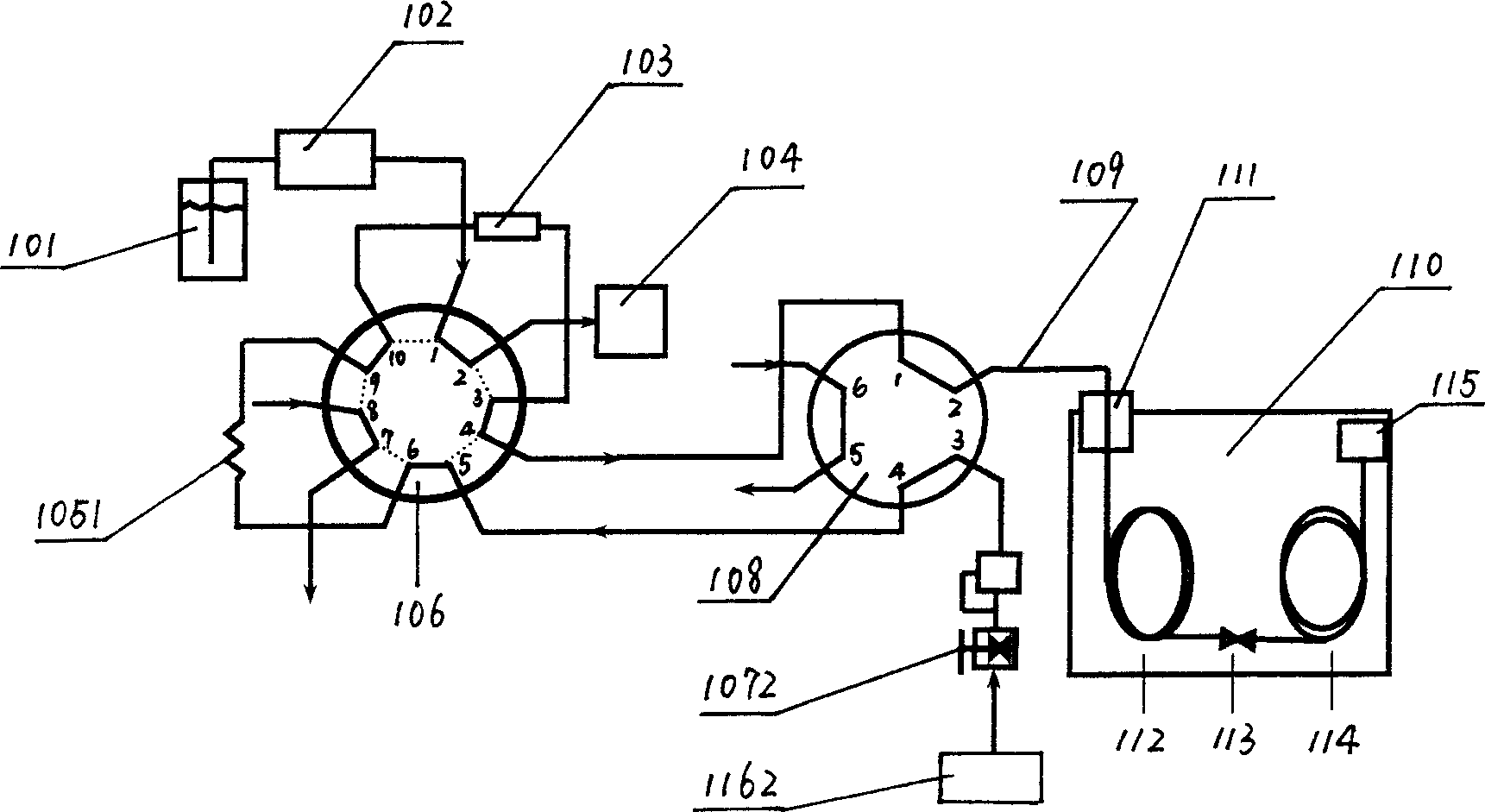

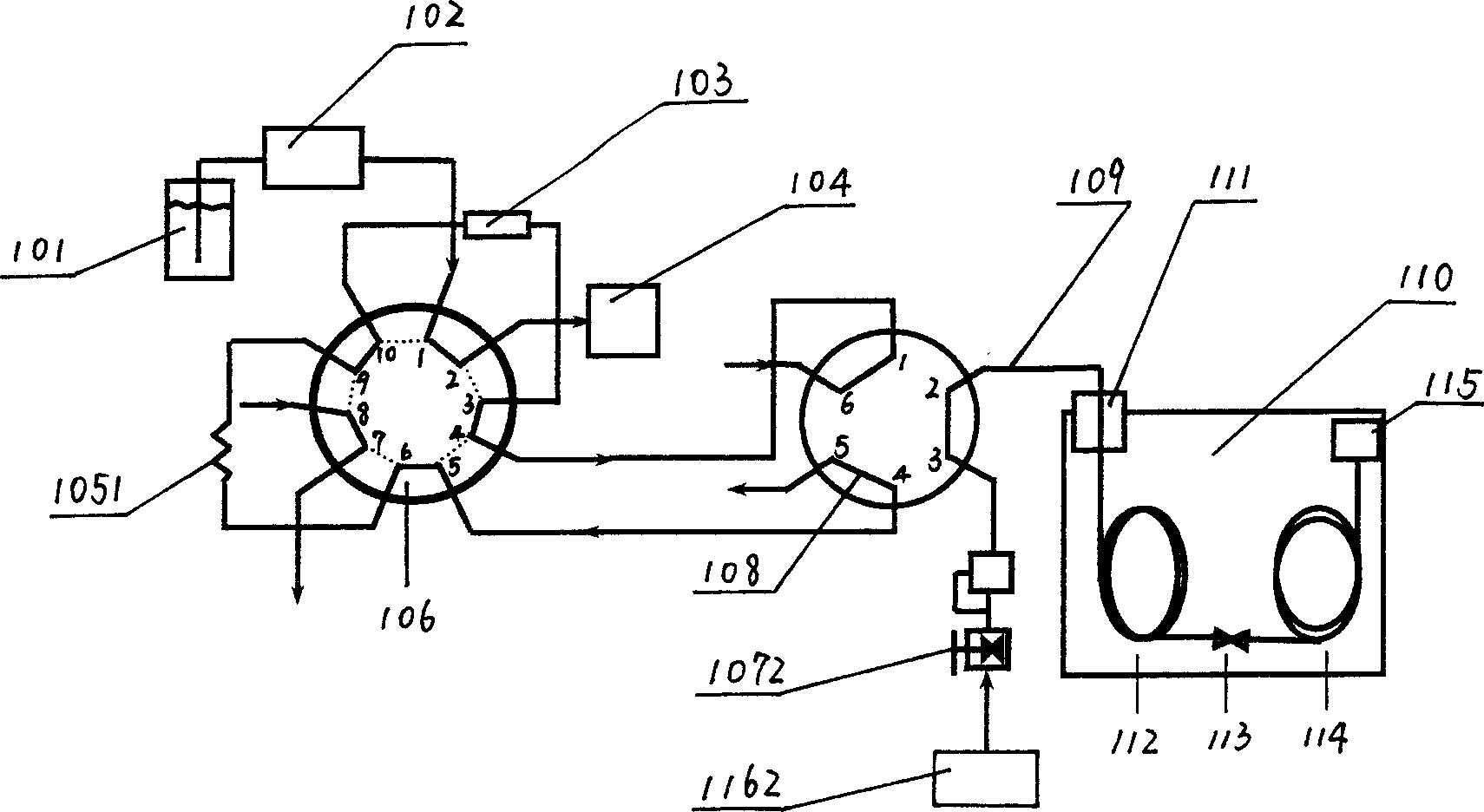

[0047] Such as Figure 2A ~ Figure 2C Shown is a schematic diagram of part of the sampling device for accelerated solvent extraction coupled with gas chromatography. The solvent delivery high-pressure pump 102 is connected to the No. 1 position of the ten-way valve 106, the inlet pipe 201 and the outlet pipe 211 of the extraction tank 2 are respectively connected to the No. 10 and No. 3 positions of the ten-way valve 106, and the pressure sensor 104 is connected to the ten-way valve. The No. 2 position of the valve 106, the two ends of the first metering tube 1051 are respectively connected to the No. 9 and No. 6 positions of the ten-way valve 106, and the No. 8 and No. 7 positions of the ten-way valve 106 are respectively for the first fixed position. The measuring tube 1051 is injected into the inlet and outlet of the solution, the first auxiliary carrier gas 1161 is connected to the 5th position of the ten-way valve 106 through the first steady flow valve 1071, the 4th posi...

Embodiment 3

[0060] The experimental device and method are the same as in Example 1, and the environmental pollutants in the soil are extracted with a pressurized solvent. The solvent is 1:1 n-hexane:acetone, the extraction pressure is 10 MPa, the extraction temperature is 100° C., and the extraction time is 10 minutes.

[0061] The accelerated solvent extraction device of the present invention is combined with a gas chromatograph, and the sample is pretreated and analyzed online with a gas chromatograph, and all or part of the extract flowing out of the accelerated solvent extraction device is transferred to a gas chromatograph for analysis, specifically The operation steps are: put the sample into the extraction cell body 204 in the extraction cell 2, seal it, and place the ten-way valve 106 at the solvent extraction position; use the solvent delivery high-pressure pump 102 to introduce the solvent into the extraction cell body 204 in the extraction cell 2 Pressurize at 5-20MPa, and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com