Rotation detection device

一种旋转检测、旋转角的技术,应用在测量装置、使用电/磁的方法的装置、采用电/磁装置传递传感构件等方向,能够解决装置调整成本上升、多时间、成本上升等问题,达到降低纹波成分的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

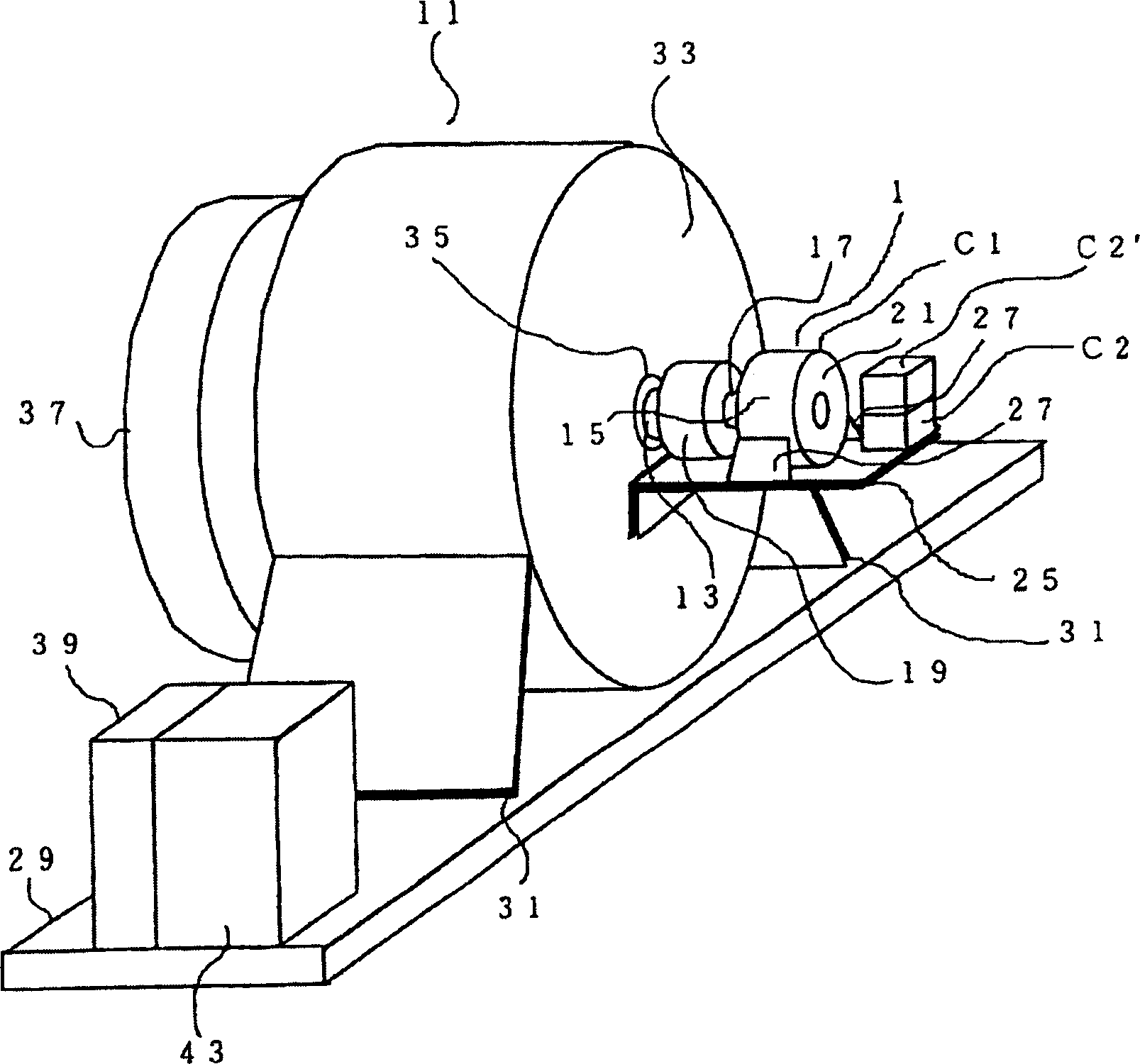

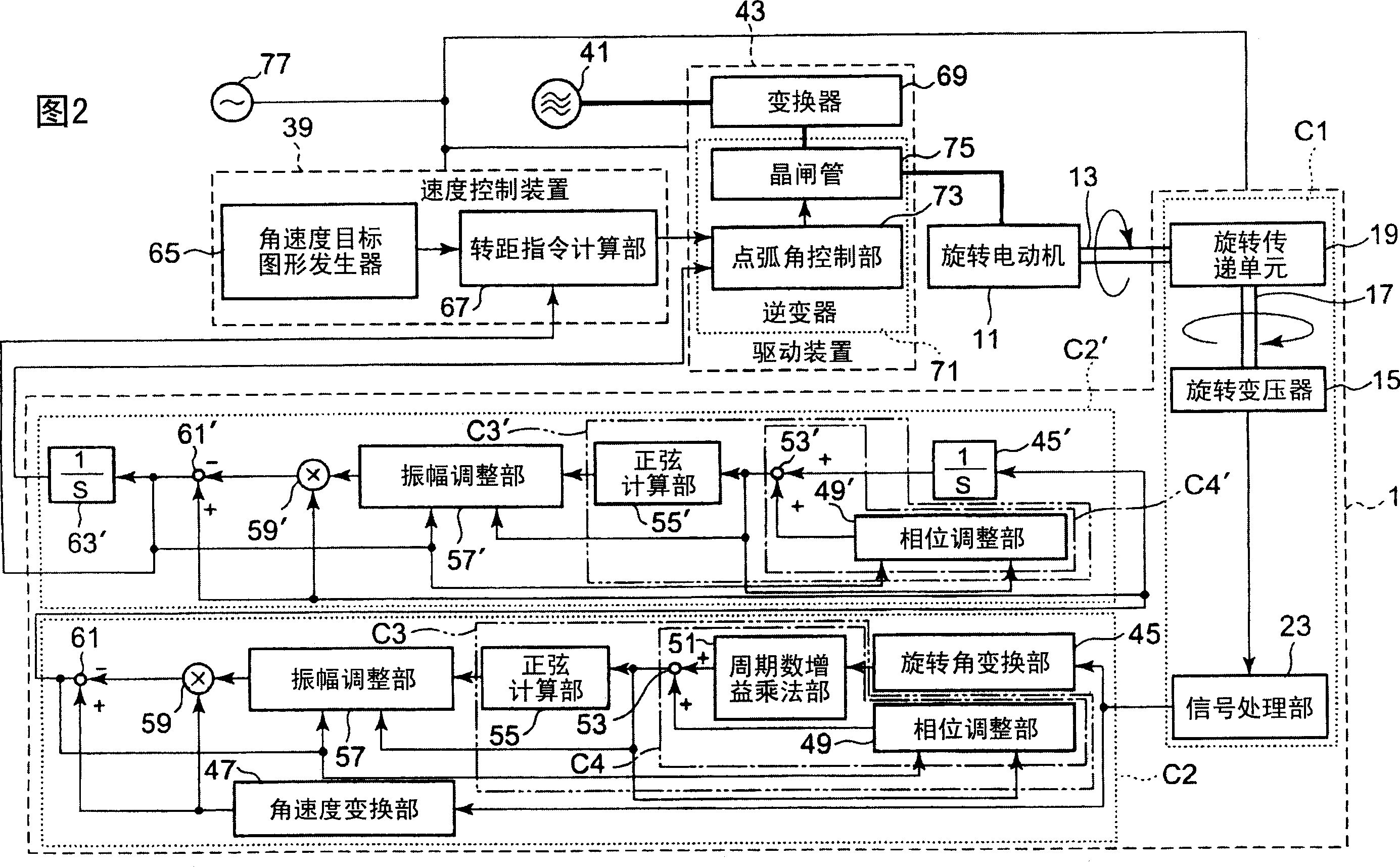

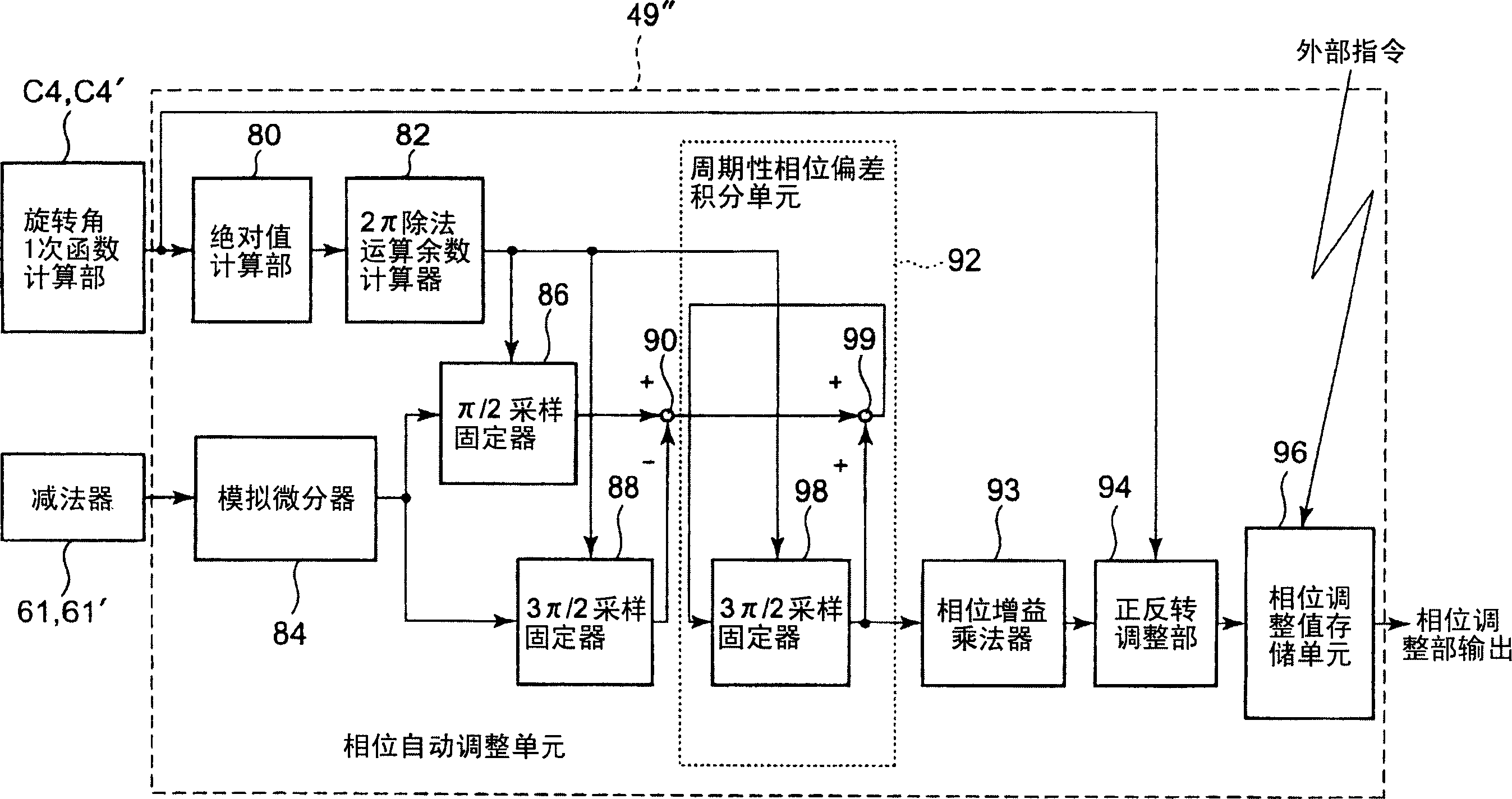

[0105] exist figure 1 In FIG. 4 , the rotation detection device of the first embodiment is indicated by 1 as a whole, and the rotation detection device 1 includes a rotation detection unit C1 and rotation calculation units C2 and C2 ′.

[0106] The rotation detecting unit C1 is composed of a resolver 15 that is mounted on the rotating electric machine 11 as a detection target and outputs a voltage proportional to the rotation angle of the rotor rotating shaft 13 of the rotating electric machine 11, and a rotor (not shown) of the resolver 15 . The directly connected input rotation shaft 17 and the rotation transmission unit 19 that transmits the rotation of the rotor rotation shaft 13 to the input rotation shaft 17 are configured.

[0107] The rotation transmission unit 19 connected with one end of the rotor rotating shaft 13 has, for example, a universal joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com