Laser beam incident optical device

An optical device, laser technology, applied in the direction of laser, laser welding equipment, laser parts, etc., can solve the problems of increased cost, increased cost, increased number of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

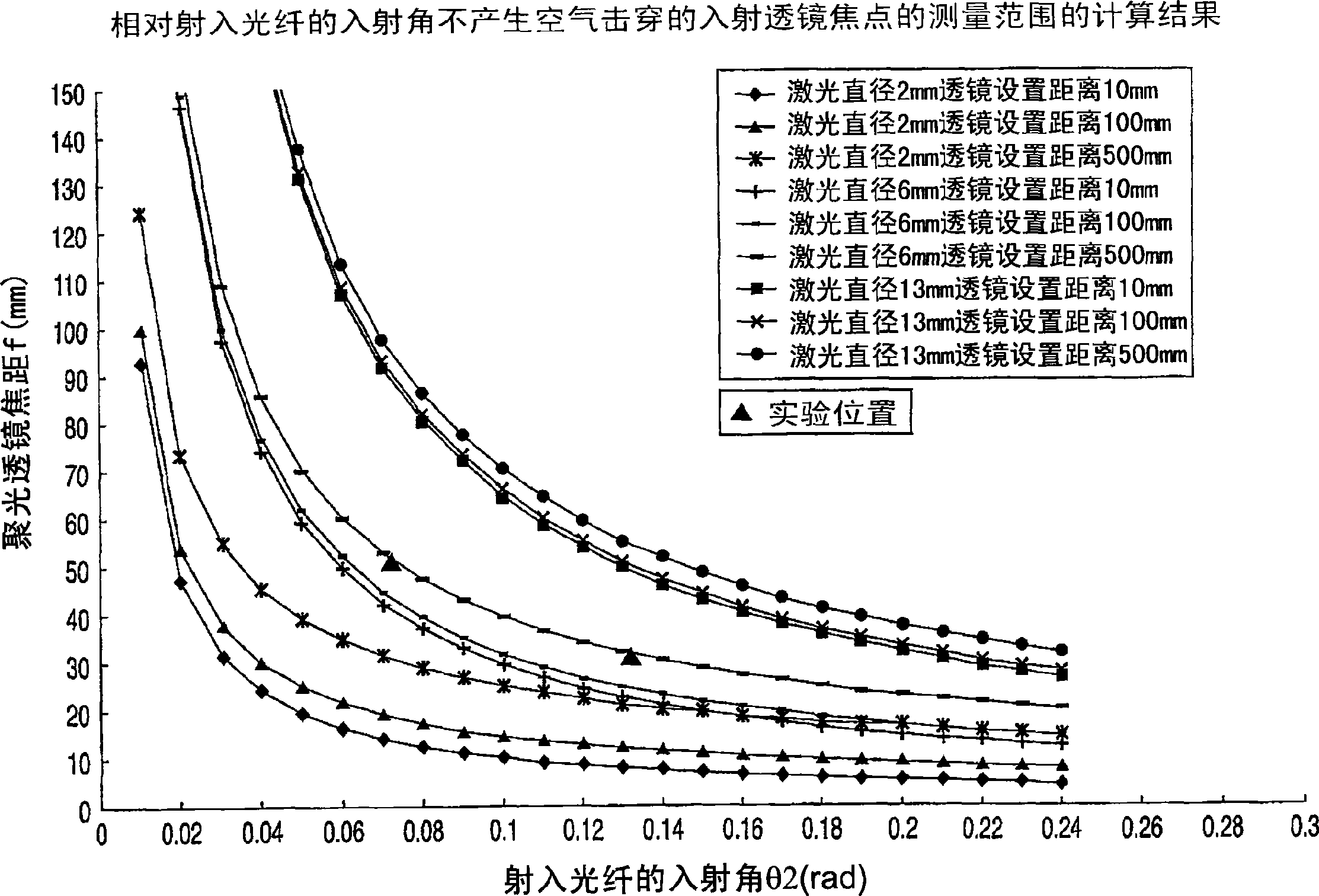

[0032] use Figure 1 to Figure 9 , an embodiment of the laser incident optical device will be described.

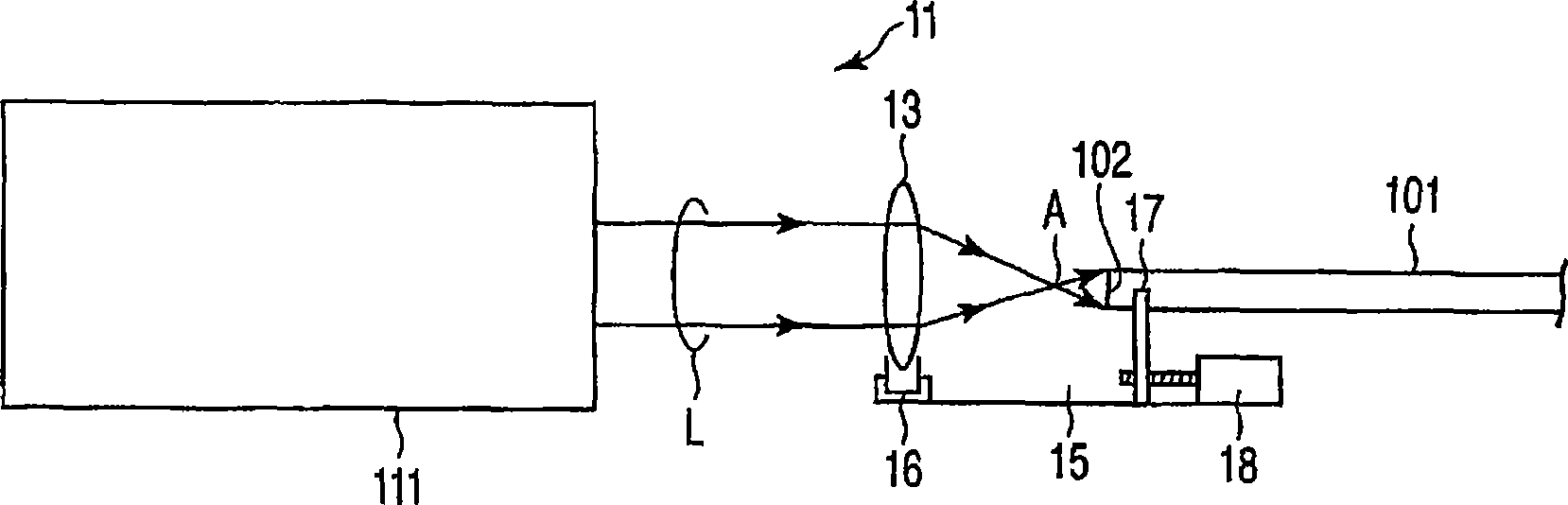

[0033] Such as figure 1 As shown, the laser incident optical device 11 is a pulsed laser light generated by a solid-state laser oscillator (laser device) 111 with a peak power greater than 10 MW without damaging the optical fiber 101, and is injected into the specified laser beam with less loss. The device of the incident end face 102 of the optical fiber 101 with the core diameter and cladding thickness.

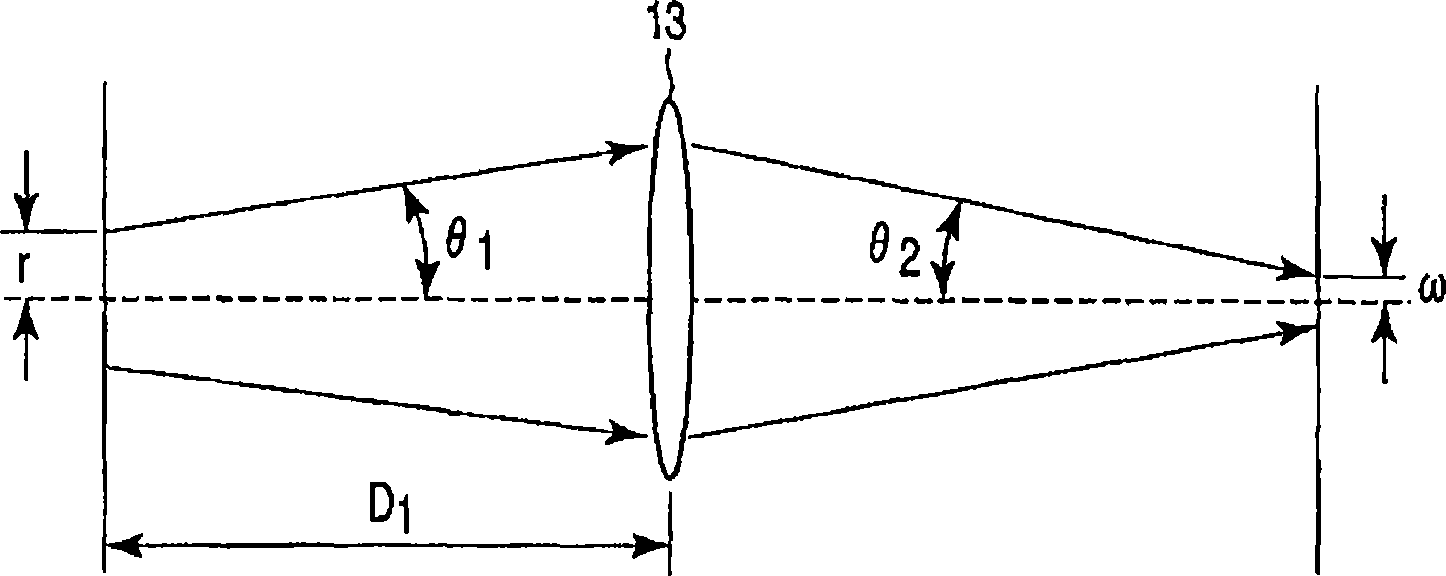

[0034] The laser incident optical device 11 has: the condensing lens 13 that condenses the laser light L whose cross-sectional diameter of the beam supplied by the solid-state laser oscillator 111 is a predetermined size; It is an optical fiber position adjustment mechanism 15 at a certain distance.

[0035] The condenser lens 13 is an inexpensive and read...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com