Remote controlled stepless variable frequency speed regulating towing vehicle

A technology of variable frequency speed regulation and traction vehicles, which is applied in the field of railway vehicles, can solve the problems of waste of equipment resources, short transportation distance, low operating cost, etc., and achieve the effect of ensuring safety and health, high work efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

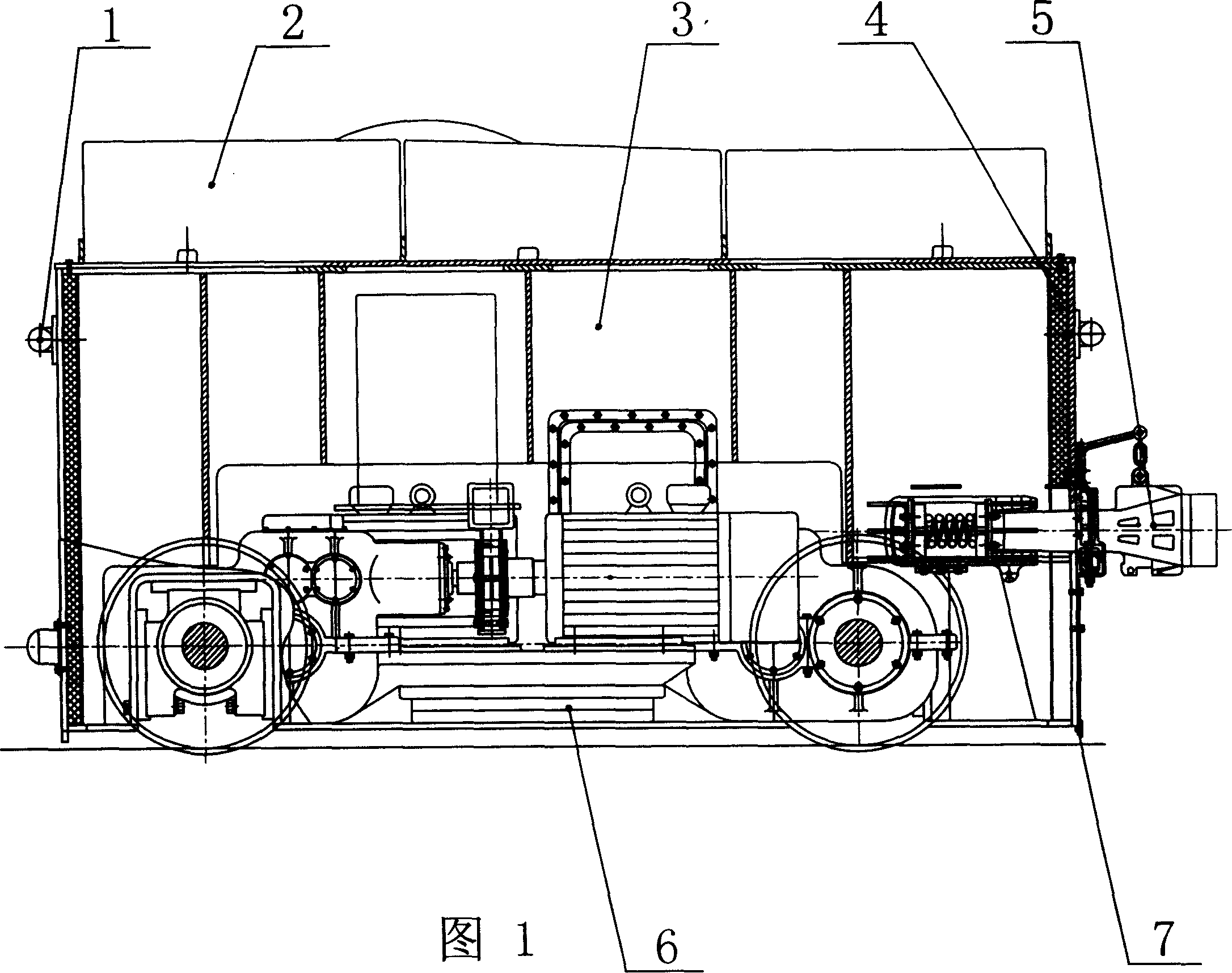

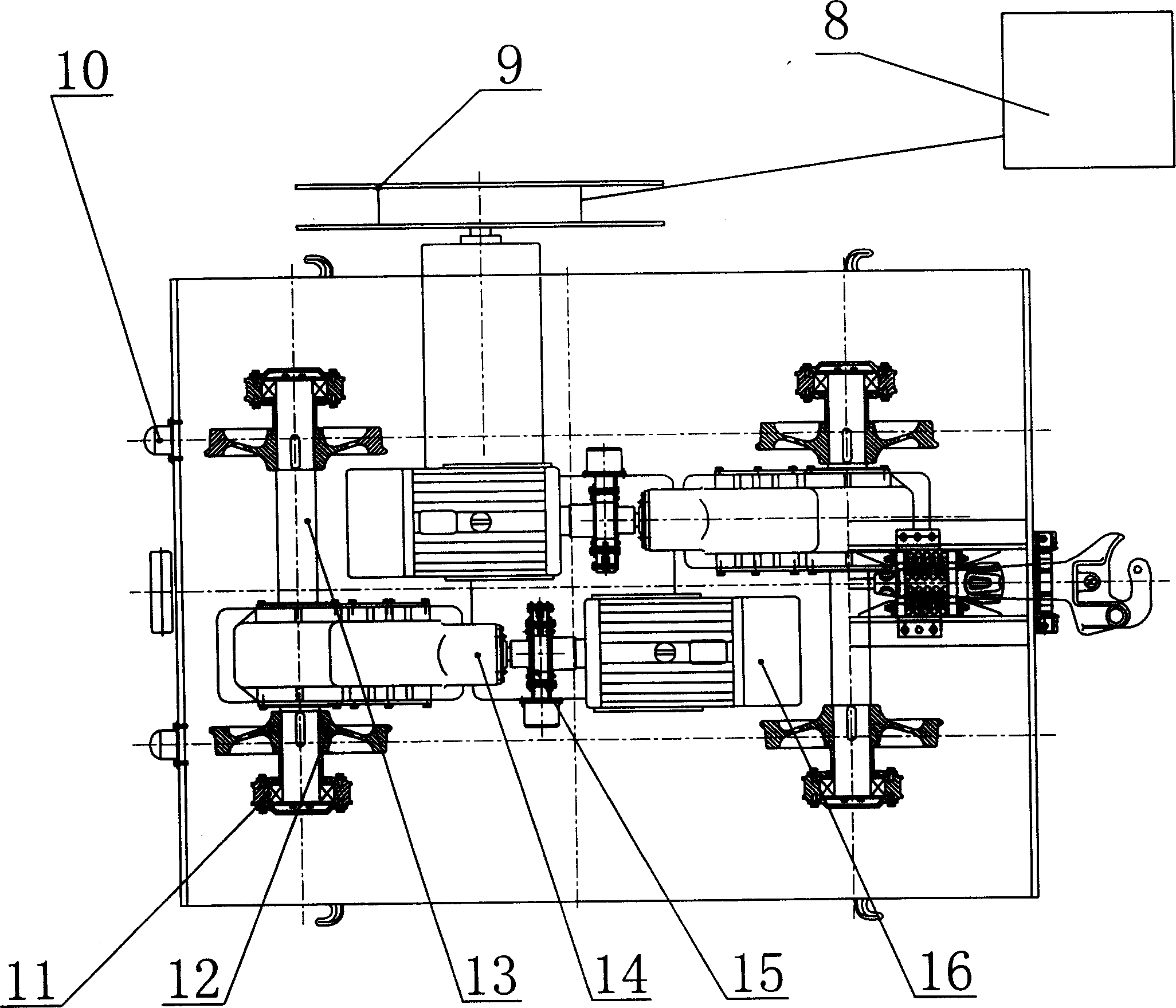

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0021] Figure 1, figure 2 As shown, the remote control stepless frequency conversion speed regulation tractor of the present invention comprises car body 3, axle shaft 13, wheel 12, motor 16, speed reducer 14, it is characterized in that described car body 3 connects front and rear through bearing and bearing box 11 The two axles 13 are connected, and the two axles 13 are loaded into two shaft-mounted speed reducers 14, and the motor is connected with the two shaft-mounted speed reducers 14 through a coupling with a brake wheel. The machine is fixed together by connecting plate 6, and a torque cable reel 9 is installed on the side of car body 3, and one end of the cable on this reel is connected with the terminal box on the car body, and the frequency conversion motor 16, electromagnetic brake are connected by the terminal box 15. The sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com