Scanning probe of atomic force microscope

An atomic force microscope and scanning probe technology, applied in the field of scanning probes, can solve the problems of inconvenient observation and adjustment of laser light spots, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and specific embodiments.

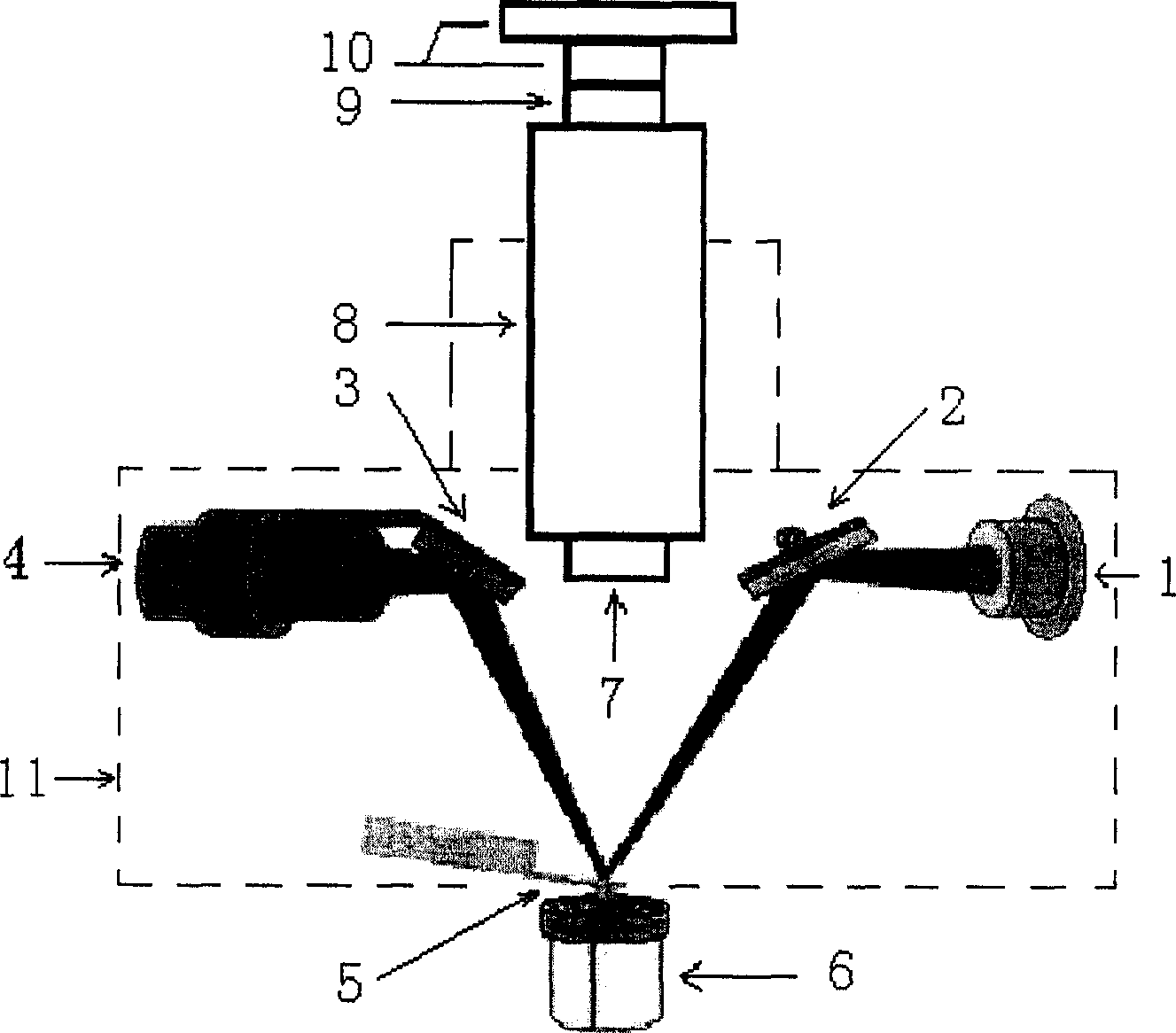

[0014] Such as figure 1 As shown, the scanning probe of the present invention includes a laser 1, a mirror 2, a mirror 3, a four-quadrant photoelectric position detector 4, a micro cantilever 5, an objective lens 7, a focusing lens barrel 8, an eyepiece 9, and a CCD 10. After the laser 1 in the scanning probe emits a laser beam, it will be reflected on the micro cantilever 5 with a needle tip through the mirror 2, and the micro cantilever will reflect the laser light to the four-quadrant photoelectric position detector 4 through the mirror 3.

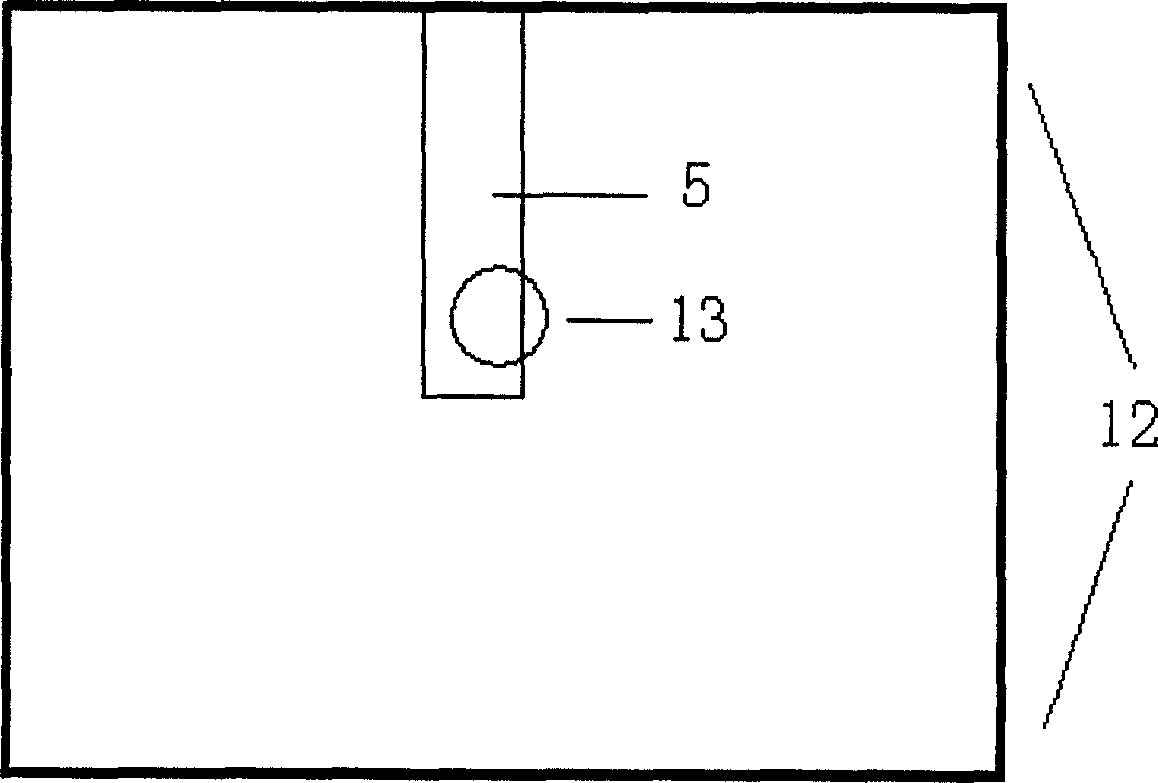

[0015] The focusing lens barrel 8 is an adjustable telescopic lens barrel, which is fixed on the top of the scanning probe housing and is located directly above the micro cantilever 5. The main body of the scanning probe housing 11 is cylindrical, with a diameter of about 100 mm and a height of about 80 mm. The lower pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com