Method for waterproofing connection part of covered wire

A technology for covering wires and waterproofing, applied in the parts, connections, and connection end caps of connecting devices, etc., can solve the problems of worry about waterproofness, low fluidity of hot melt adhesives, and difficulty in filling, etc., and achieve the performance price. Excellent, low cost, reliable waterproofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] Hereinafter, examples are given and the present invention will be described in more detail. In addition, the performance evaluation in each Example and a comparative example was performed by the following method.

[0093]

[0094] Made of soft vinyl chloride resin, thickness: 1mm

[0095]

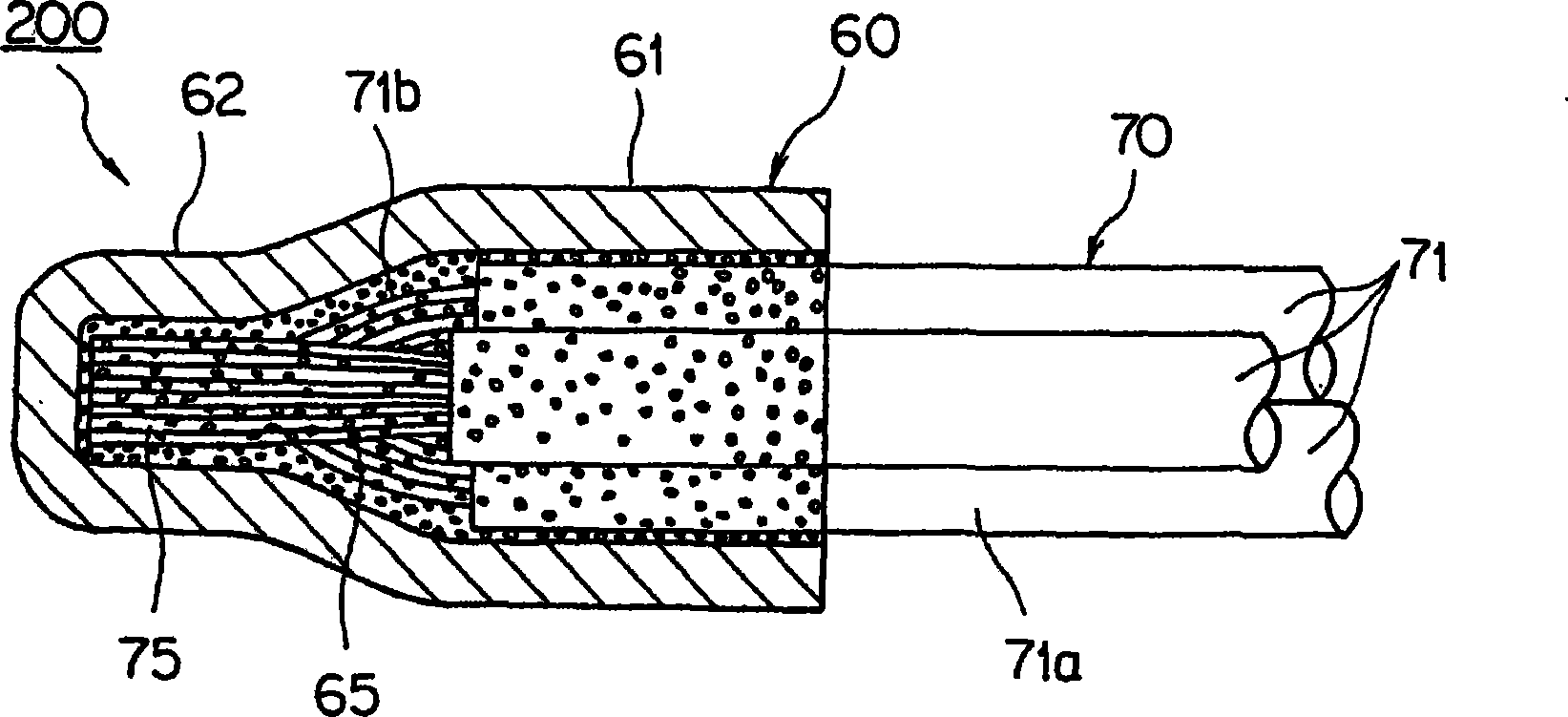

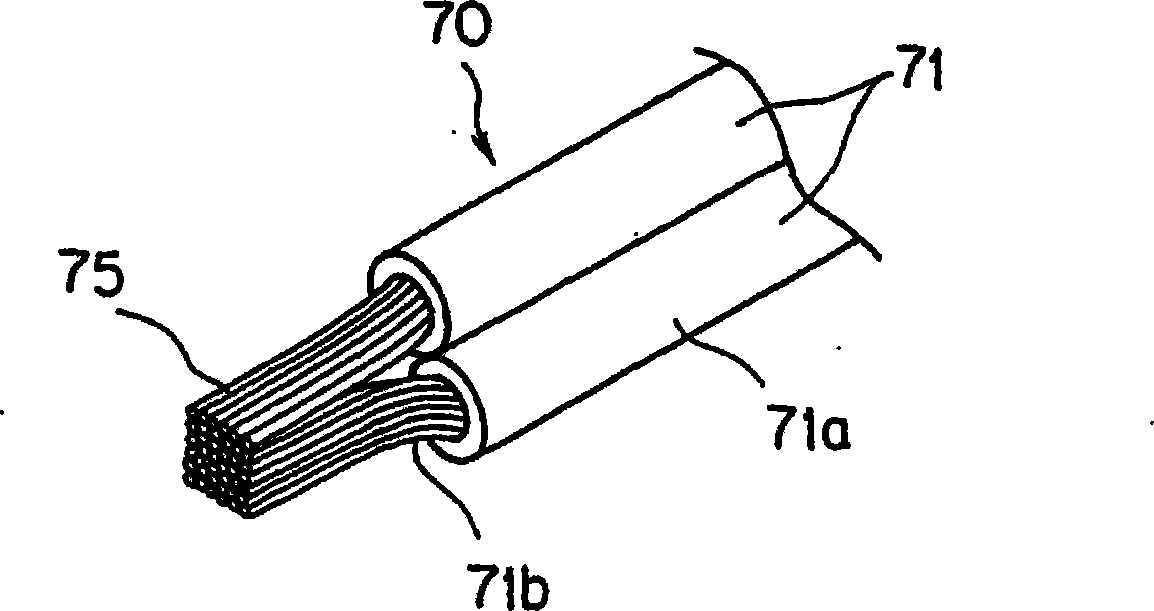

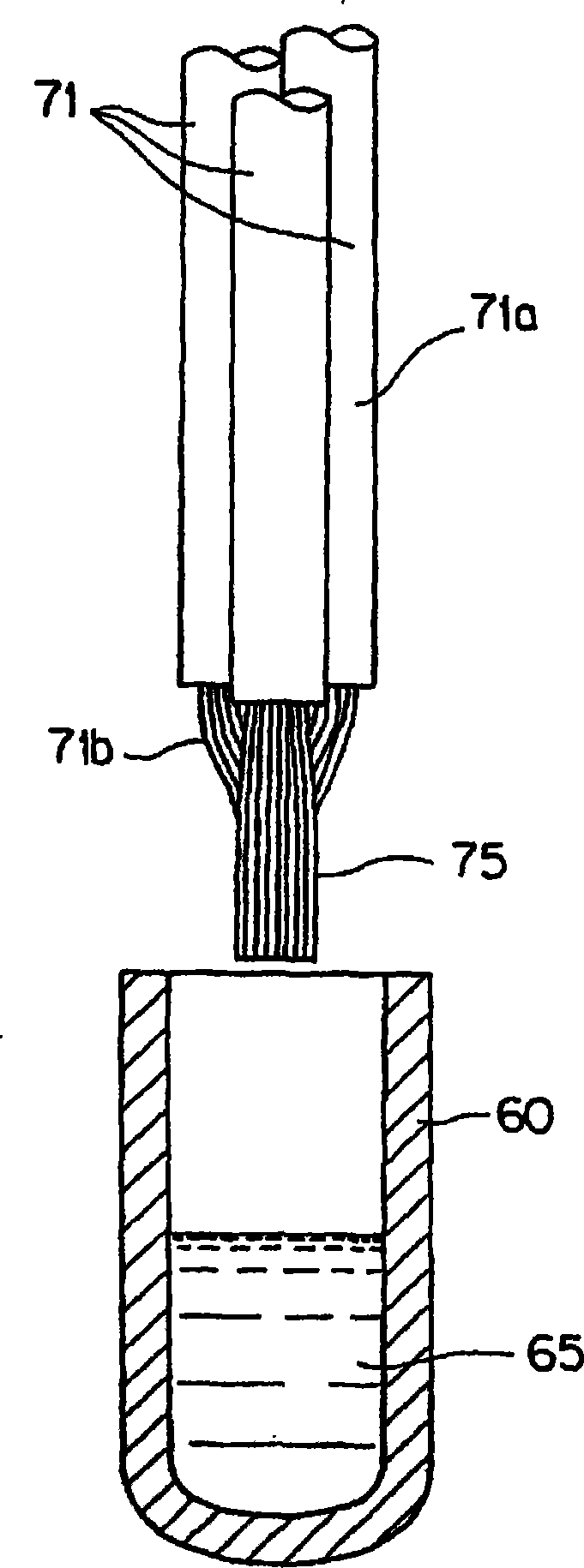

[0096] An electric wire assembly formed by crimping the core wires at one end of ten covered electric wires

[0097]

[0098] Curable sealing materials having the compositions shown in Table 1 and Table 2 were prepared, and respective characteristics were evaluated as follows. In addition, for comparison, the curable sealing material of the composition shown in Table 3 was also examined similarly.

[0099] [viscosity]

[0100] The viscosity at 25° C. was measured using an E-type viscometer.

[0101] [Coagulation time (set time)]

[0102] According to JIS K6861, a copper test piece was used, and the time until the predetermined adhesive strength was reached was defined as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com