(111) silicon based micro mechanical acceleration sensor and its manufacture

An acceleration sensor and micro-machine technology, applied in the measurement of acceleration, velocity/acceleration/impact measurement, instruments, etc., can solve the problems of increased process cost, high stress, complex process, etc., to reduce the difficulty of the manufacturing process, reduce the manufacturing cost, The effect of ensuring symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

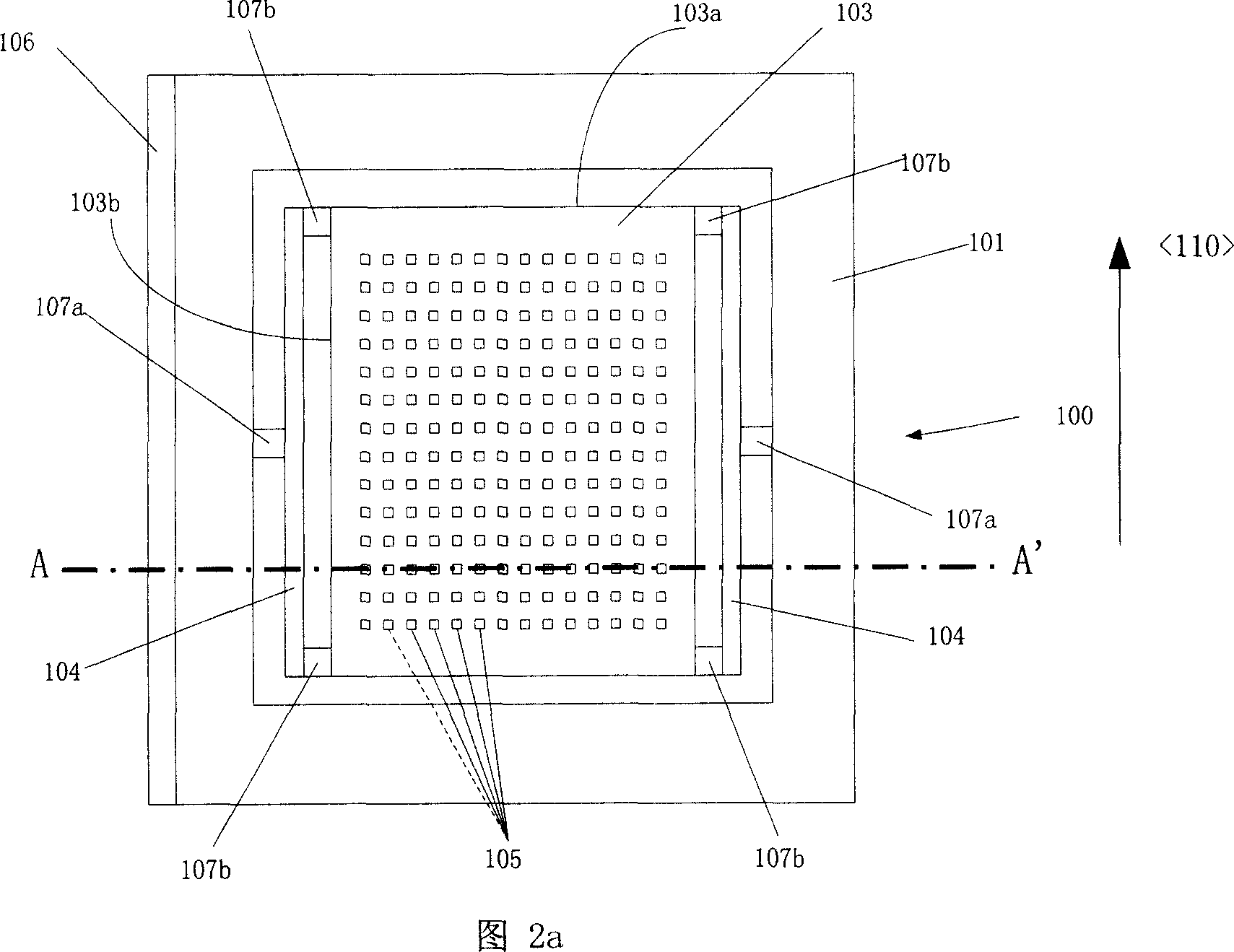

[0085] The structural features and manufacturing process of the present invention are further explained below in conjunction with the accompanying drawings.

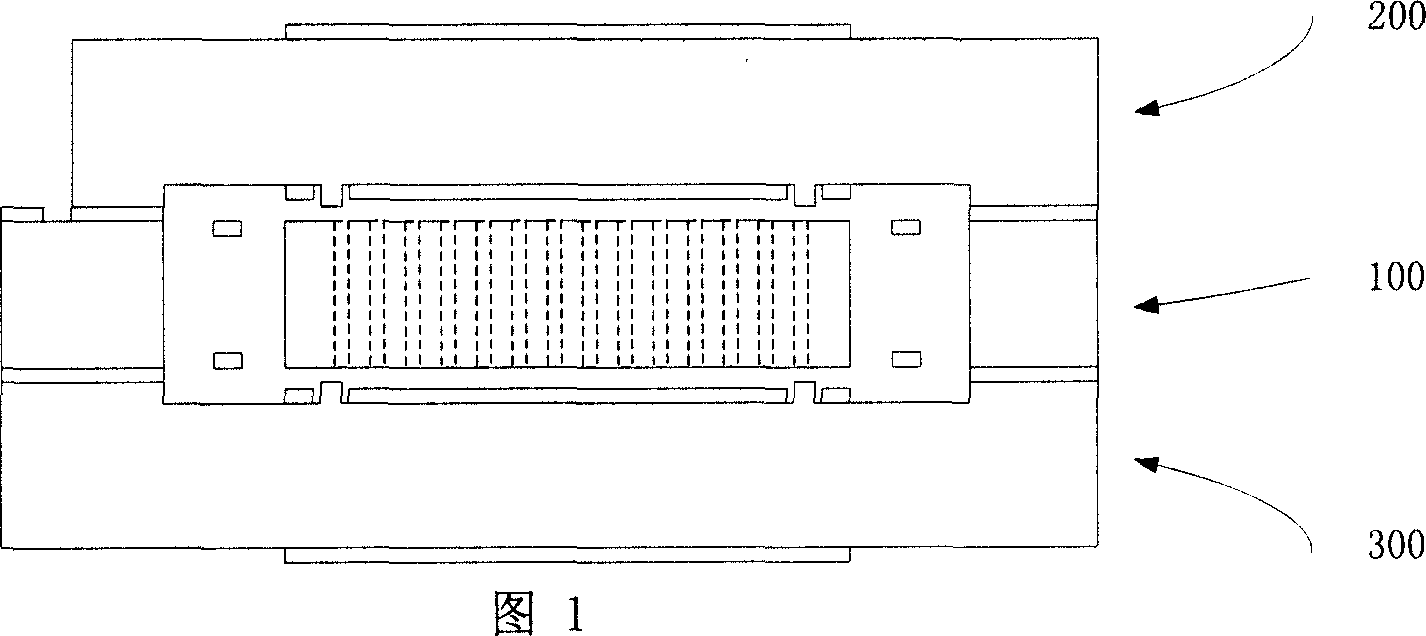

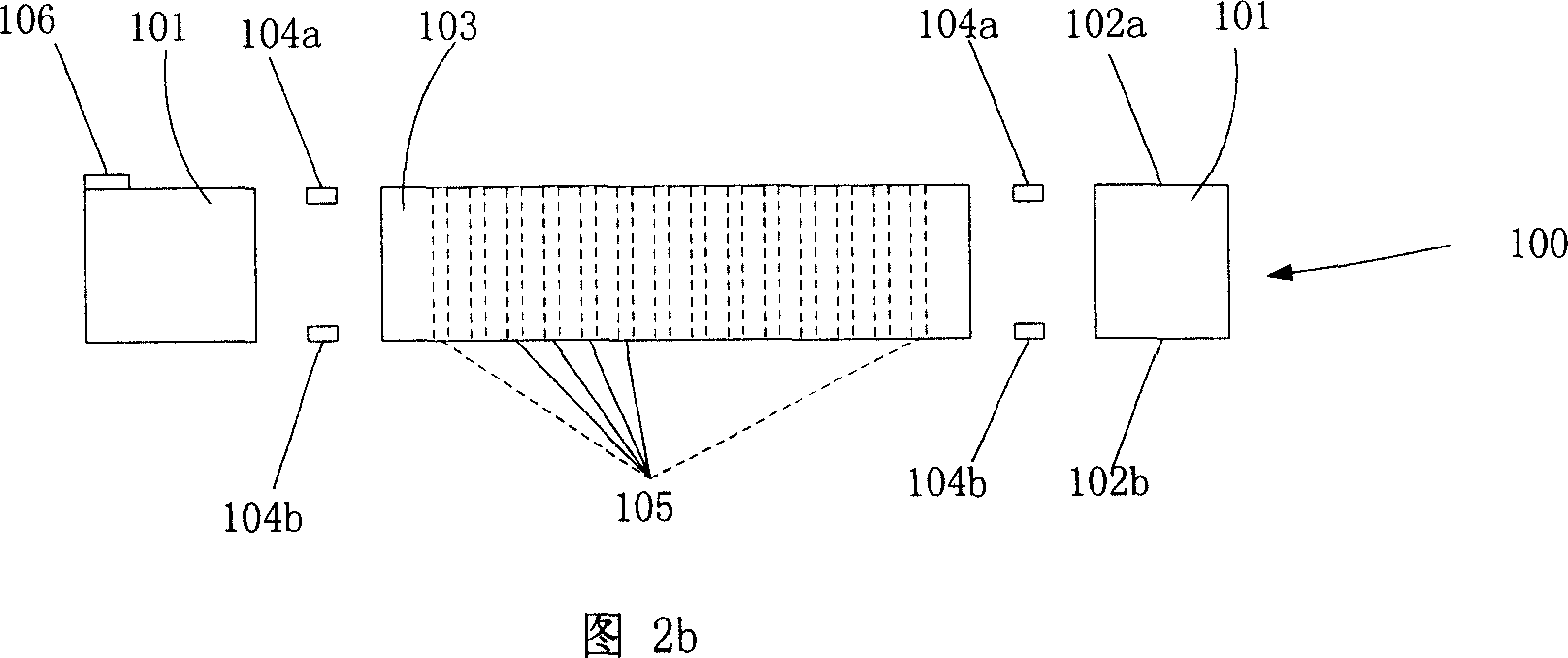

[0086] The present invention provides a (111) silicon-based micromechanical acceleration sensor and a manufacturing method thereof. The sensor is composed of a (111) single crystal silicon substrate 100, an upper substrate 200 and a lower substrate 300 each, and

[0087] a) On the (111) silicon substrate 100 there are inertial mass blocks 103, at least a pair of elastic suspension beams 104, and a frame; the elastic suspension beams 104 are symmetrical up and down relative to the (111) silicon substrate 100, and one end of each elastic suspension beam 104 is connected on the inertial mass block 103, and the other end is connected to the frame 101;

[0088] b) The inertial mass 103 can move perpendicular to the (111) direction of the surface of the silicon substrate 100 under the support of the elastic cantilever beam 104...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com