Modular high frequency detection card

A detection card and high-frequency technology, applied in the field of detection cards, can solve problems such as low manufacturing yield, high unit price, and general products without structure, and achieve low module cost and eliminate internal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

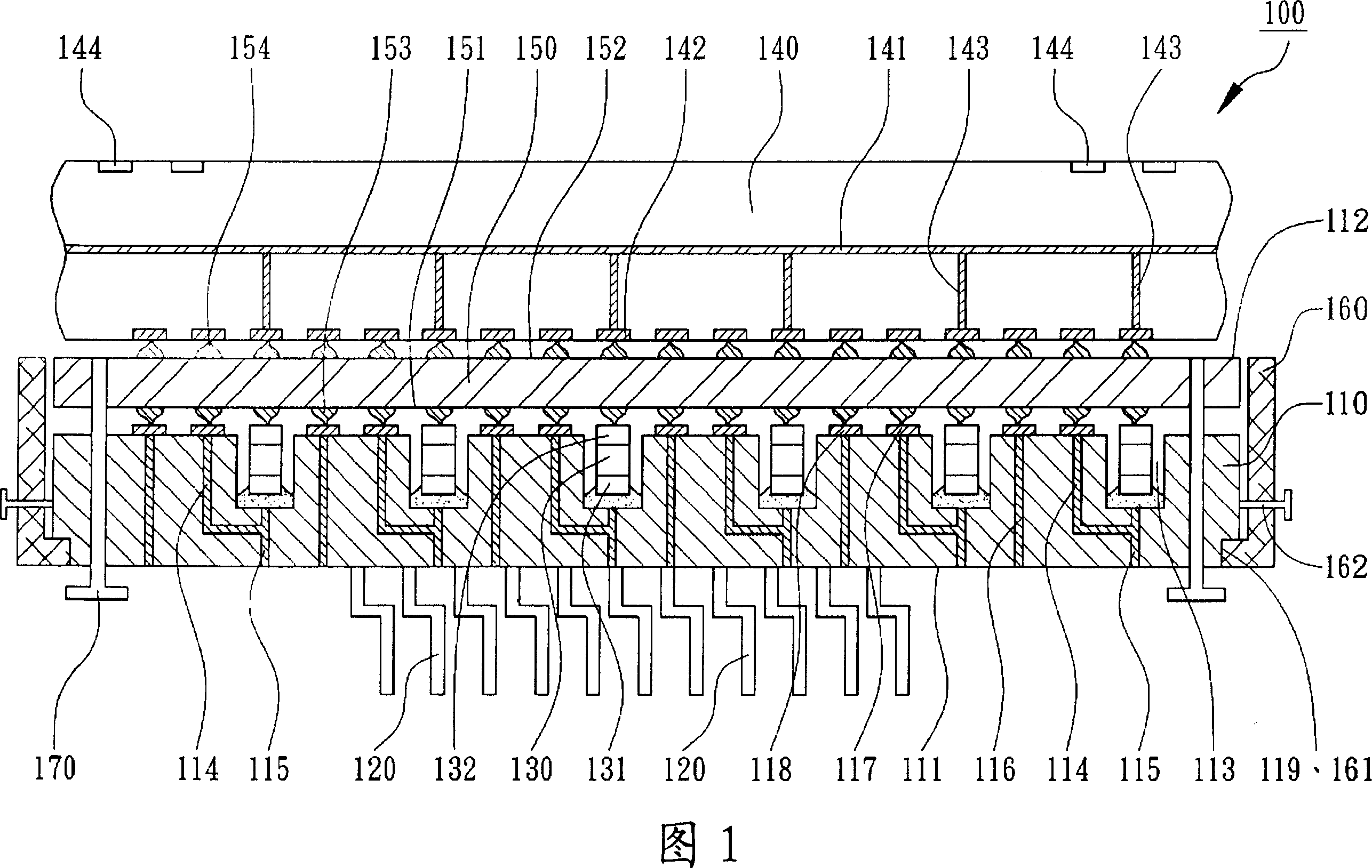

[0058] Please refer to Fig. 1, which is the first specific embodiment of the present invention. This modular high-frequency detection card 100 mainly includes a detection panel 110, a plurality of decoupling components 130 (decouplingcomponent), and a circuit carrier board. 140 and an interface board 150, the probe panel 110 is used as the first electrical transmission substrate for probing the integrated circuit to be tested. In this embodiment, the probe panel 110 is a multilayer ceramic circuit with dense circuits In other embodiments, the probe panel 110 can be selected from one of glass substrates, wafers and printed circuit boards. The probe panel 110 has a front side 111, a back side 112 and a plurality of The accommodating cavities 113 of 112, preferably, these accommodating cavities 113 are arranged in a matrix, and the touch panel 110 includes a plurality of power / ground lines 114, a plurality of bypass lines 115 and a plurality of signal transmission lines 116, A pl...

no. 2 Embodiment

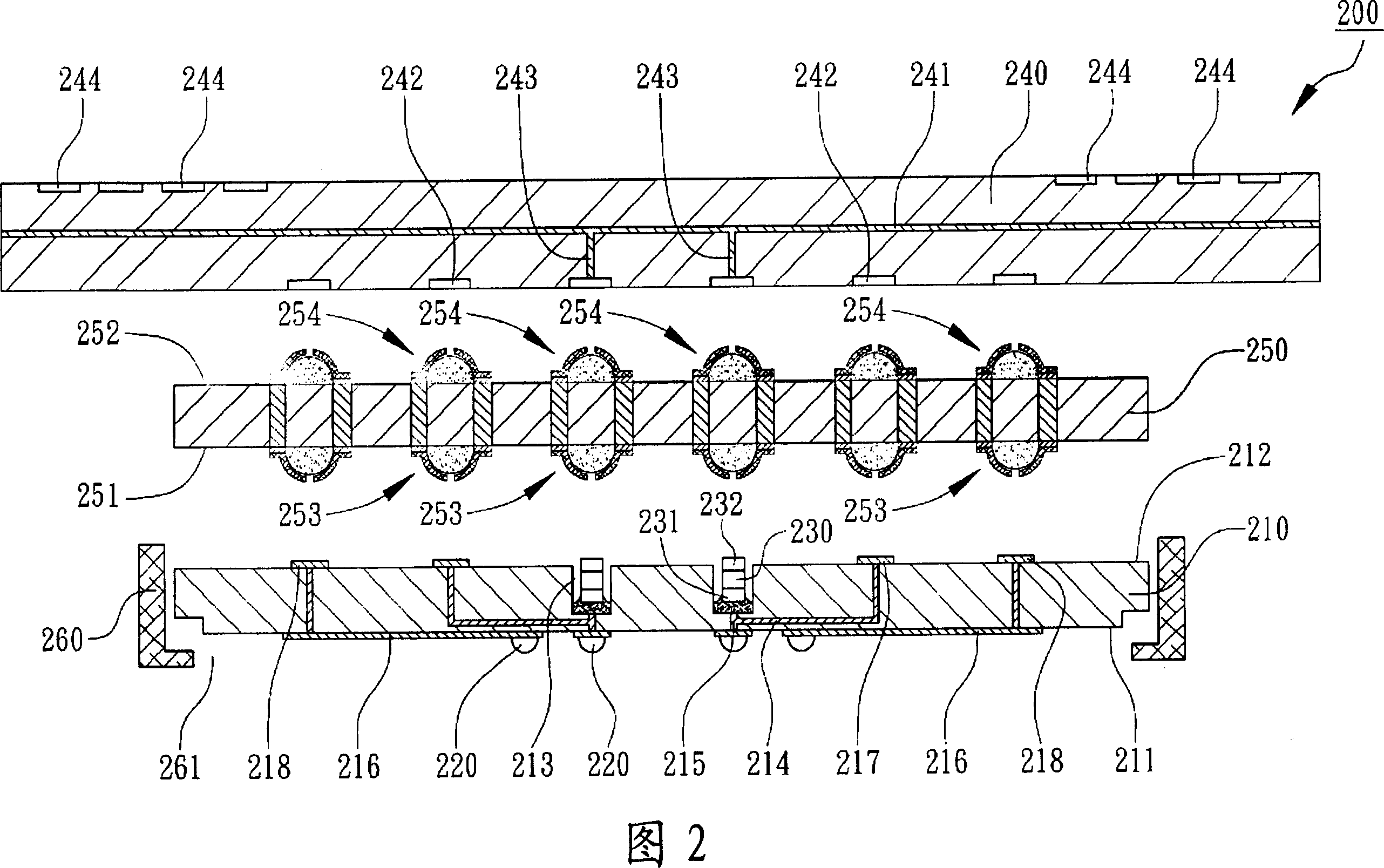

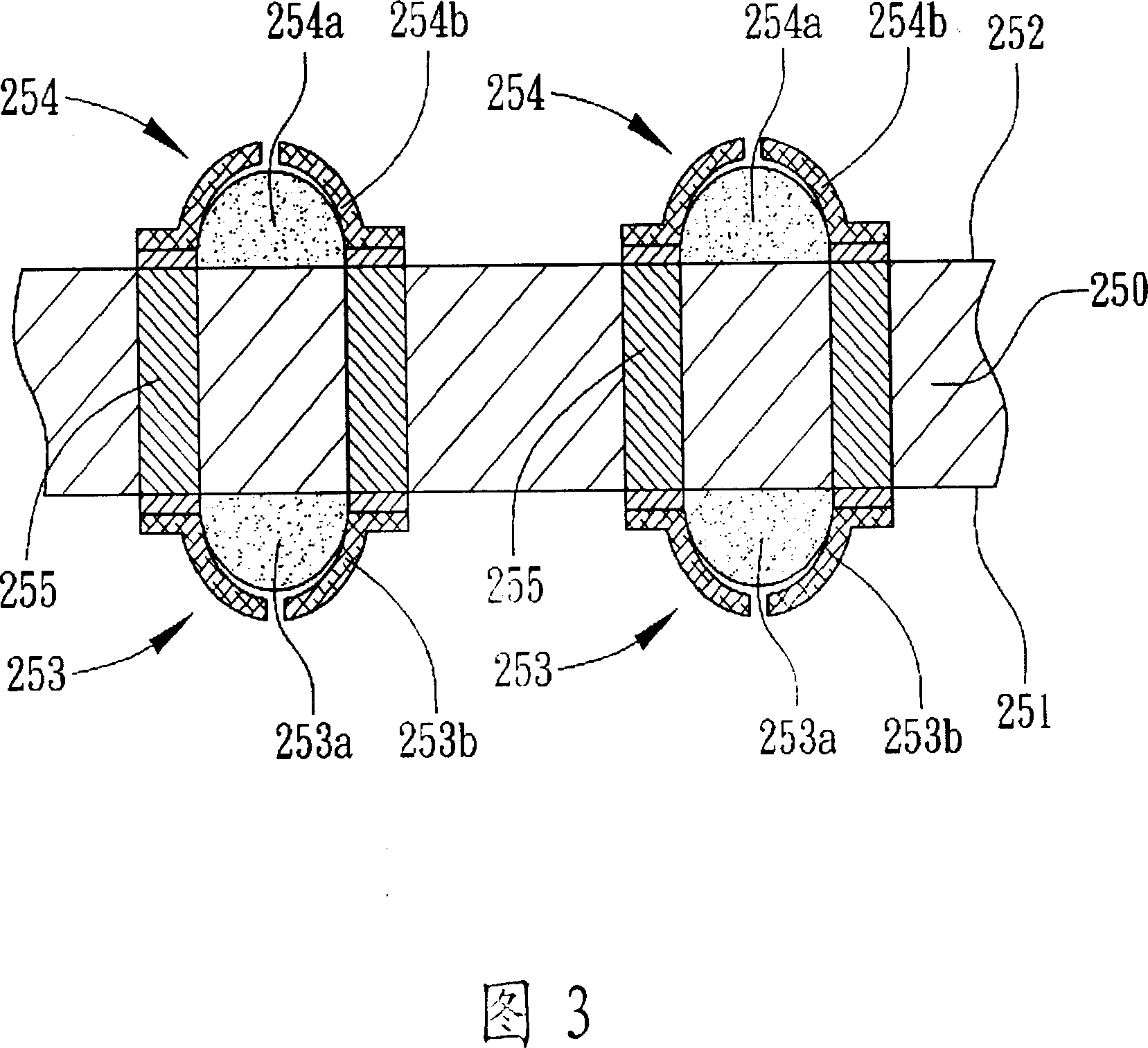

[0063] Please refer to FIG. 2 , which is the second specific embodiment of the present invention. This modular high-frequency detection card 200 mainly includes a detection panel 210, a plurality of decoupling elements 230, a circuit carrier 240 and an interposer. Panel 250, the probe panel 210 has a front side 211, a back side 212 and a plurality of accommodating holes 213 on the back side 212, the probe panel 210 includes a plurality of power / ground lines 214, a plurality of bypass lines 215 and A plurality of signal transmission lines 216, a plurality of power / ground pads 217 and a plurality of signal pads 218 are formed on the back 212 of the touch panel 210, and the power / ground lines 214 are connected to the power / ground pads 217 and the corresponding power / ground probe terminal 220, the bypass lines 215 are connected to the corresponding power / ground lines 214, and the signal transmission lines 216 are connected to the signal pads 218 and the corresponding signal probes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com