Winding for thin film coating crystal package and its constitution and manufacturing method

A technology of thin-film chip-on-chip packaging and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of electrical short circuit, inconvenience, easy pressure contact, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a detailed description of the film-on-chip packaging tape and its structure and manufacturing method according to the present invention in conjunction with the accompanying drawings and preferred embodiments. Embodiments, methods, steps, structures, features and effects thereof are described in detail below.

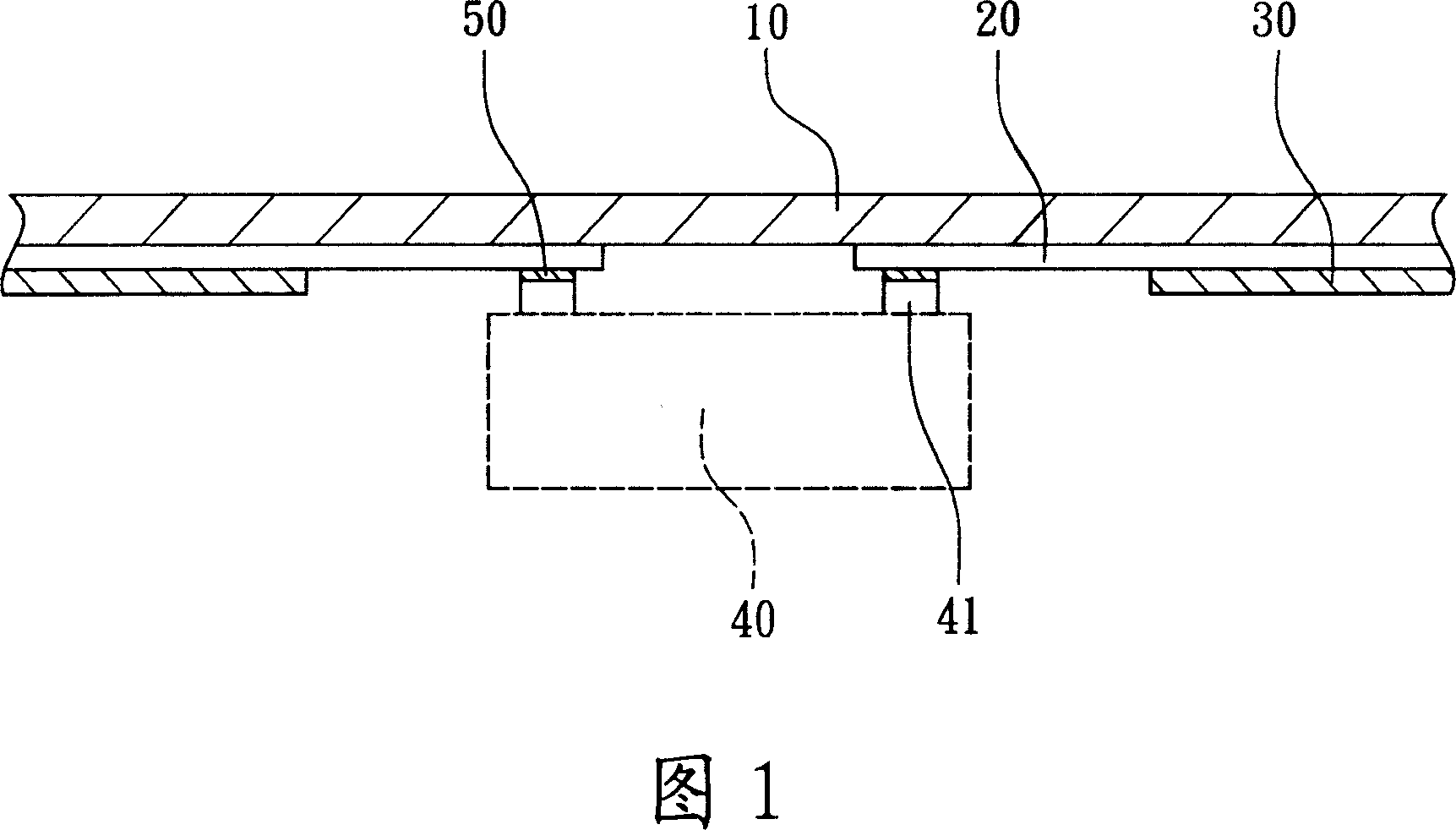

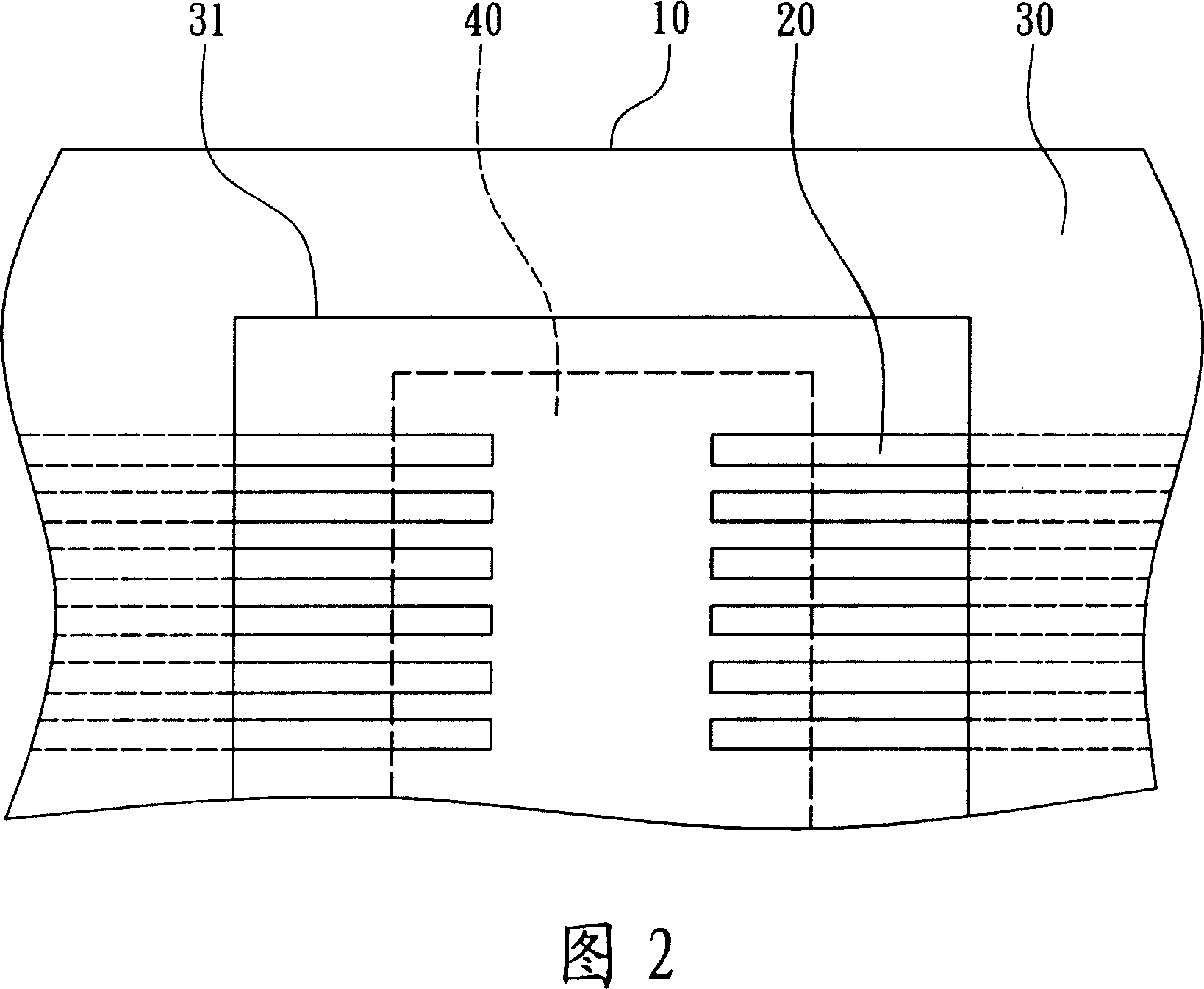

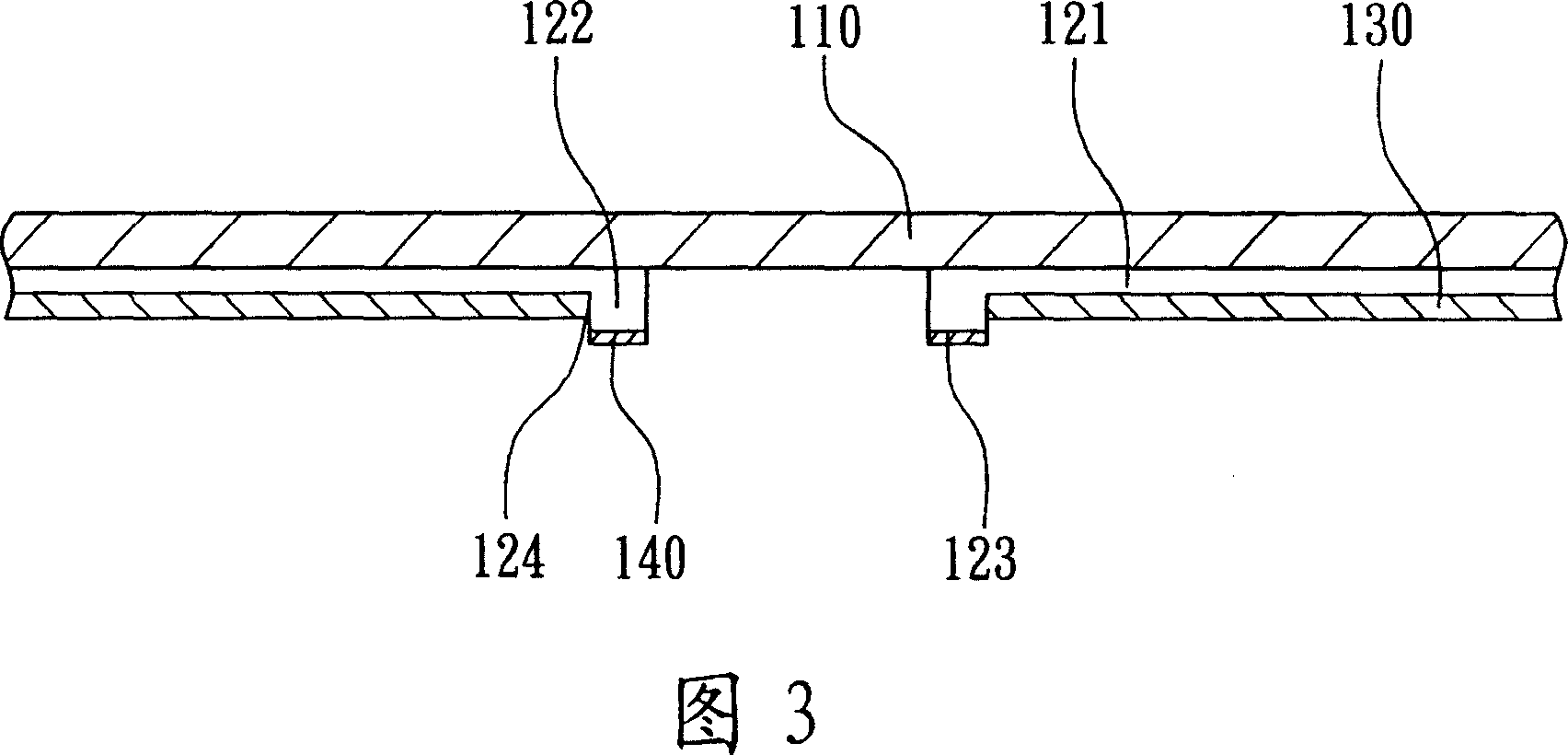

[0054] Please refer to FIG. 3 and FIG. 4 . FIG. 3 is a schematic partial cross-sectional view of a film-on-chip package tape, and FIG. 4 is a partial bottom view of the tape. In the first embodiment of the present invention, the tape mainly includes a flexible dielectric substrate 110 , a lead layer and a solder resist layer 130 . The lead layer is formed on the flexible dielectric substrate 110 , and the lead layer includes a plurality of leads 121 and a plurality of bump pads 122 . Individual leads 121 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com