A kind of preparation method of pvc floor with thermal insulation structure

A technology of floor and base material layer, applied in the direction of building structure, floor, building, etc., can solve the problems of rapid indoor heat loss, shortage of resources, inability to guarantee heat, etc., so as to avoid cracking, ensure normal operation, The effect of saving resources and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

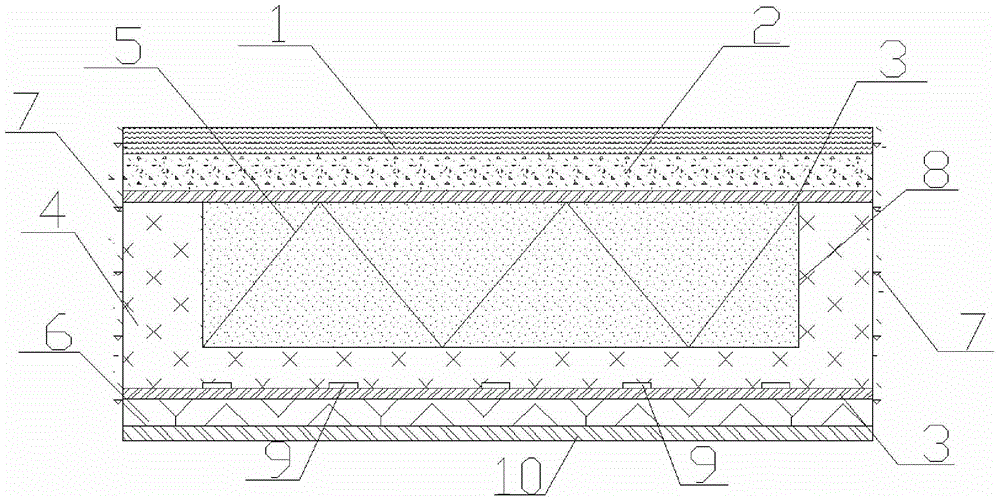

[0025] A kind of PVC floor with insulation structure provided by this embodiment, the structure is as follows figure 1 As shown, it includes PVC wear-resistant layer 1, decorative layer 2, base material layer 4 and PVC foam layer 6, and from inside to outside is PVC foam layer 6, base material layer 4, decoration layer 2 and PVC wear-resistant layer 1. It also includes a glass fiber cloth layer 3. The base material layer 4 is a PVC board. The upper and lower surfaces of the base material layer 4 are respectively provided with a glass fiber cloth layer 3, a PVC wear-resistant layer 1, a decorative layer 2, a base material layer 4, and glass fiber The superposition of the cloth layer 3 and the PVC foam layer 6 is respectively provided with a small bump 7 protruding outwards and connected therewith, and the lower end of the PVC foam layer 6 is also provided with a moisture-proof layer 10, which is a thermosetting resin waterproof Paper or plastic film, of which:

[0026] The gla...

Embodiment 2

[0028] A kind of preparation method of the PVC floor with thermal insulation structure provided in this embodiment, specifically comprises the following steps:

[0029] (1) Preparation of the substrate layer, the prepared substrate layer raw materials are manually inspected and graded at first, and unqualified ones with insect eyes, decay, excessive defects, and inconsistent sizes are removed to obtain qualified substrate layer raw materials;

[0030] (2) Excavating grooves on the upper surface of the qualified substrate layer raw materials, digging at least five notches on the lower surface of the substrate layer raw materials, and polishing the surfaces of the grooves and notches to obtain a finished substrate layer. The finished substrate layers are stacked and stored according to grades, and the storage environment avoids direct sunlight exposure;

[0031] (3) Install the support frame in the base material layer, fill the gap between the support frame and the base material...

Embodiment 3

[0035] A kind of preparation method of the PVC floor with thermal insulation structure provided in this embodiment, specifically comprises the following steps:

[0036] (1) Preparation of the substrate layer, the prepared substrate layer raw materials are manually inspected and graded at first, and unqualified ones with insect eyes, decay, excessive defects, and inconsistent sizes are removed to obtain qualified substrate layer raw materials;

[0037] (2) Excavating grooves on the upper surface of the qualified substrate layer raw materials, digging at least five notches on the lower surface of the substrate layer raw materials, and polishing the surfaces of the grooves and notches to obtain a finished substrate layer. The finished substrate layers are stacked and stored according to grades, and the storage environment avoids direct sunlight exposure;

[0038] (3) Install the support frame in the base material layer, fill the gap between the support frame and the base material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com