High frequency discharge excited gas laser oscillator

A gas laser and high-frequency discharge technology, applied in lasers, laser parts, electrical components, etc., can solve the problems of rising prices, complicated device structures, and accuracy depends on the performance of detectors, achieving a simple structure and improving laser output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

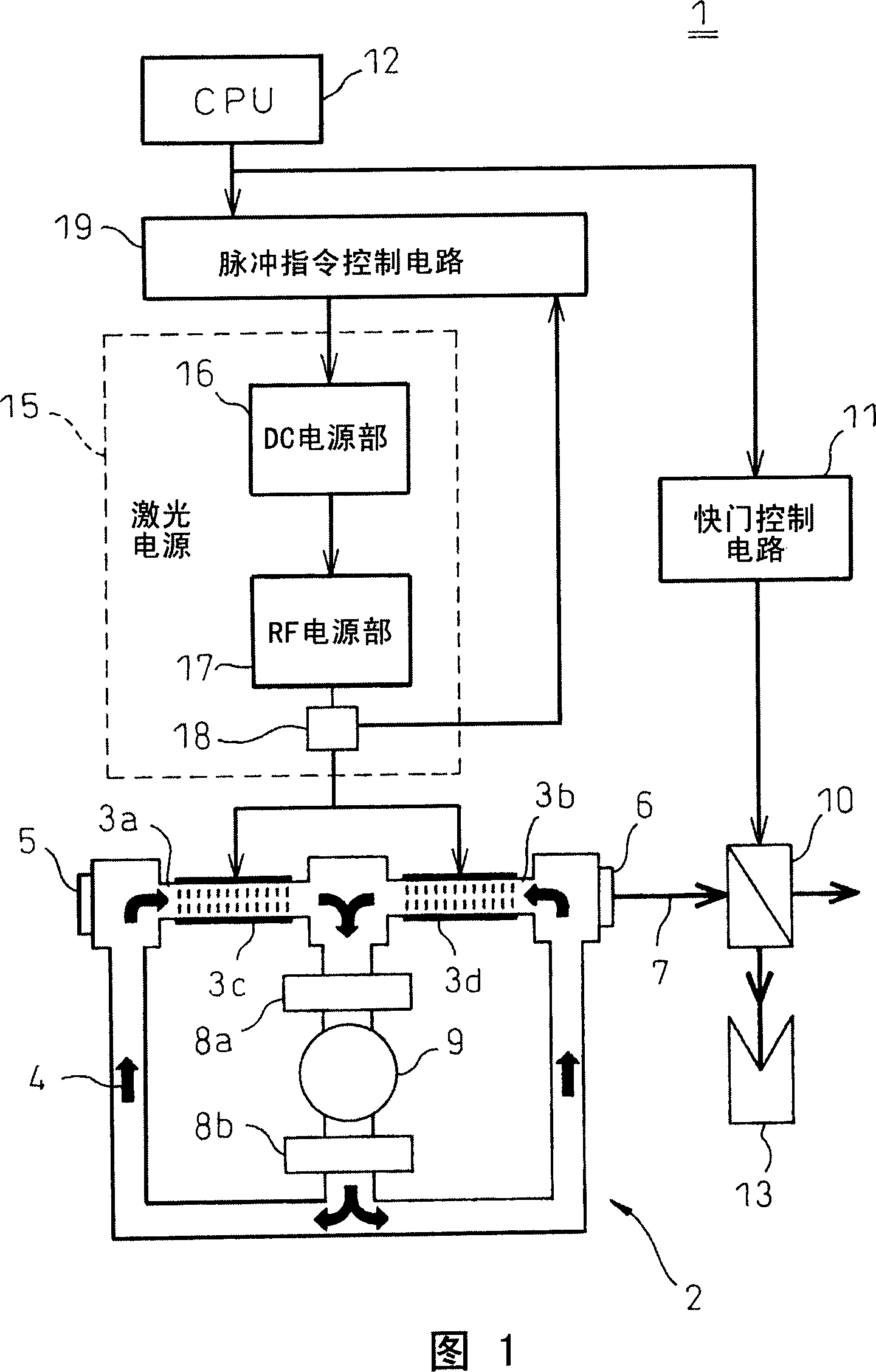

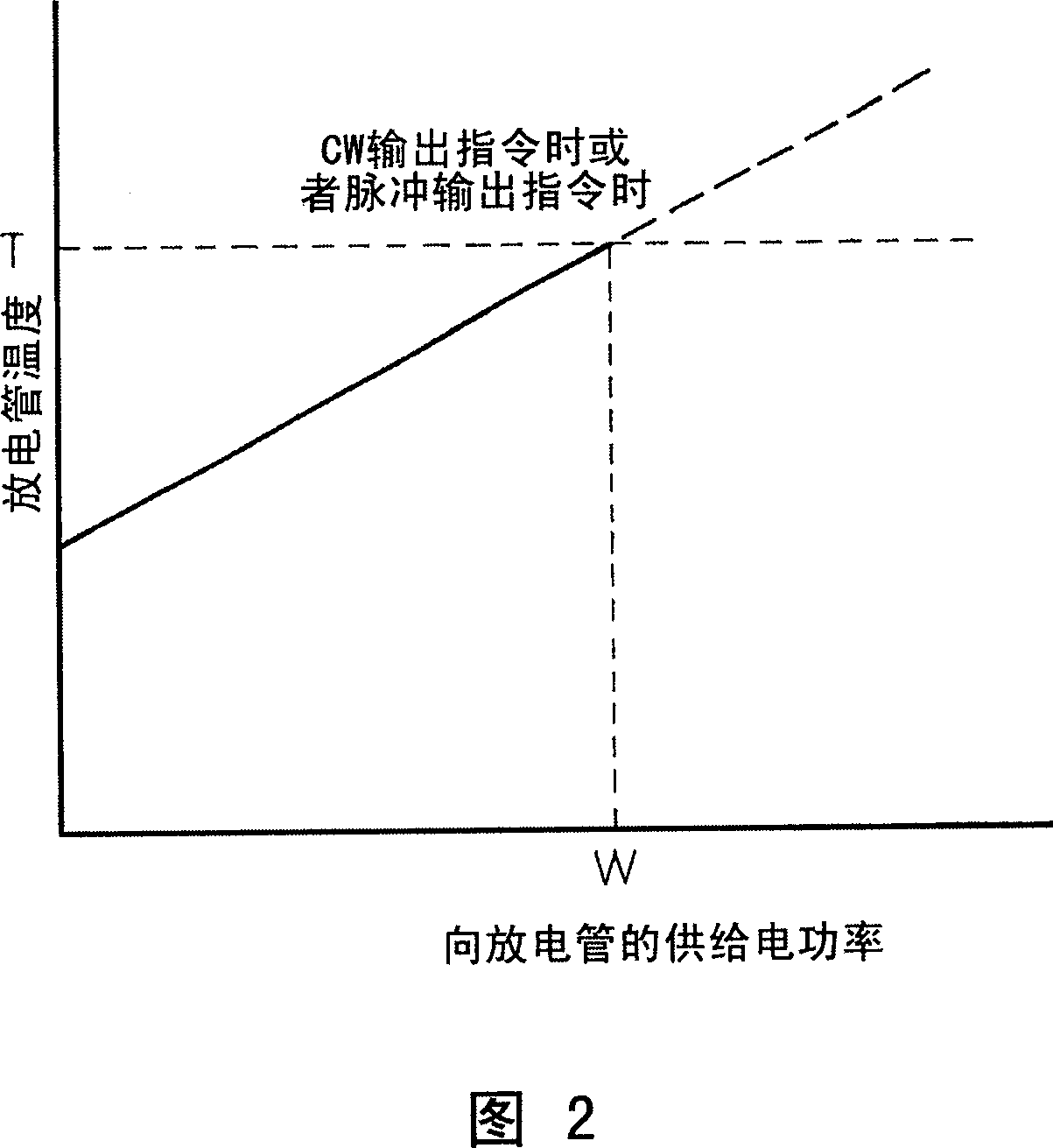

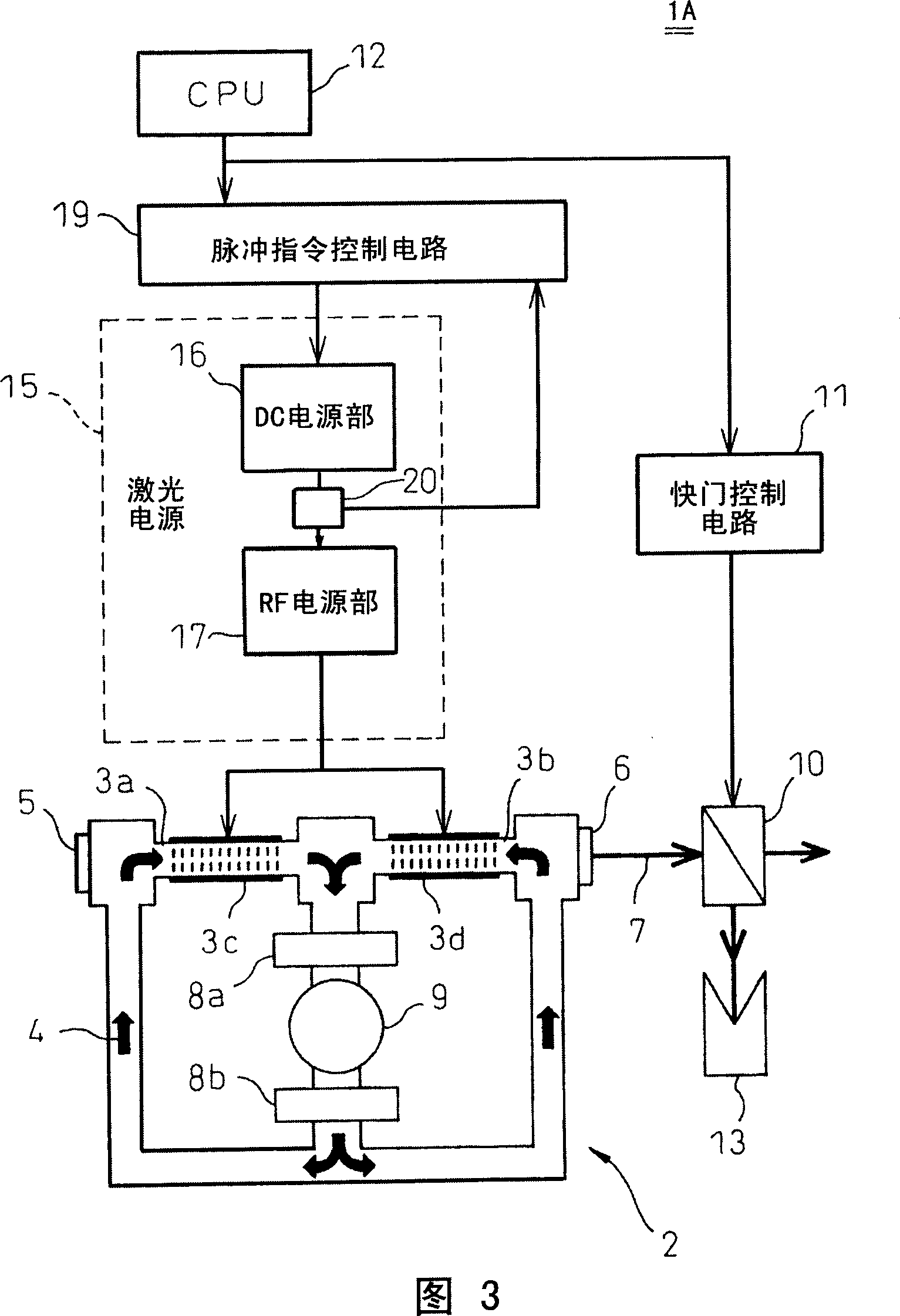

[0023] As shown in FIG. 1 , the high-frequency discharge-excited gas laser oscillator 1 of the present embodiment has an oscillator body 2, a laser power supply 15 for supplying electric power to the discharge tubes 3a and 3b of the discharge-excited laser 7, and a laser power supply 15 for detecting discharge from the laser power supply 15. The RF power detection circuit (power detection unit) 18 for supplying electric power of the tubes 3a, 3b, the pulse command control circuit (command control unit) 19 for controlling the pulse command value to the discharge tubes 3a, 3b, according to the temperature of the discharge tube and the value of the supplied power Find the allowable upper limit value W of the electric power supply (refer to FIG. 2 ), compare the allowable upper limit value W with the detected actual electric power supply, and control the pulse output command value to the discharge tubes 3a and 3b so that the actual electric power supply Do not exceed the allowable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com