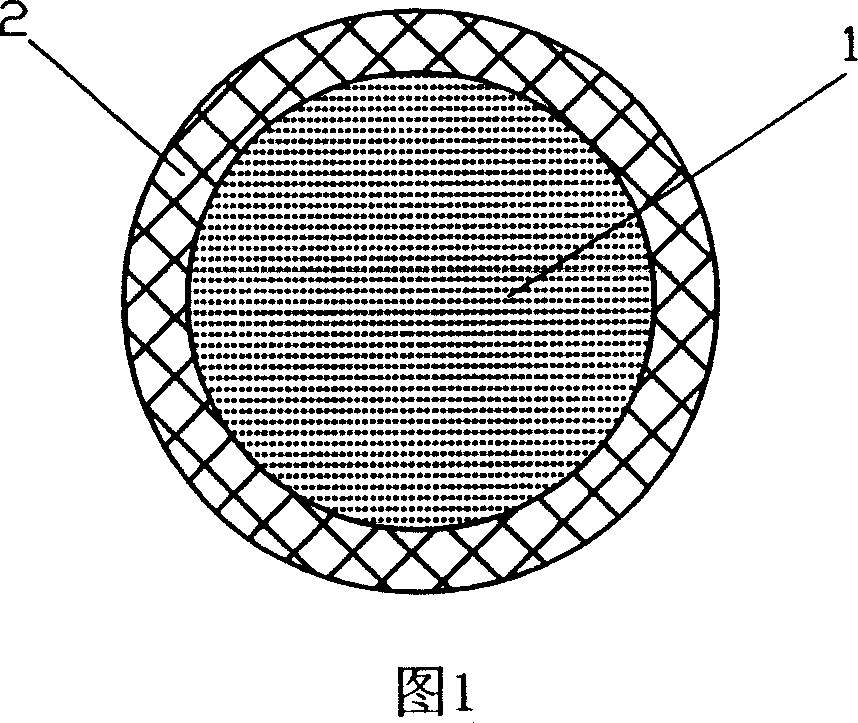

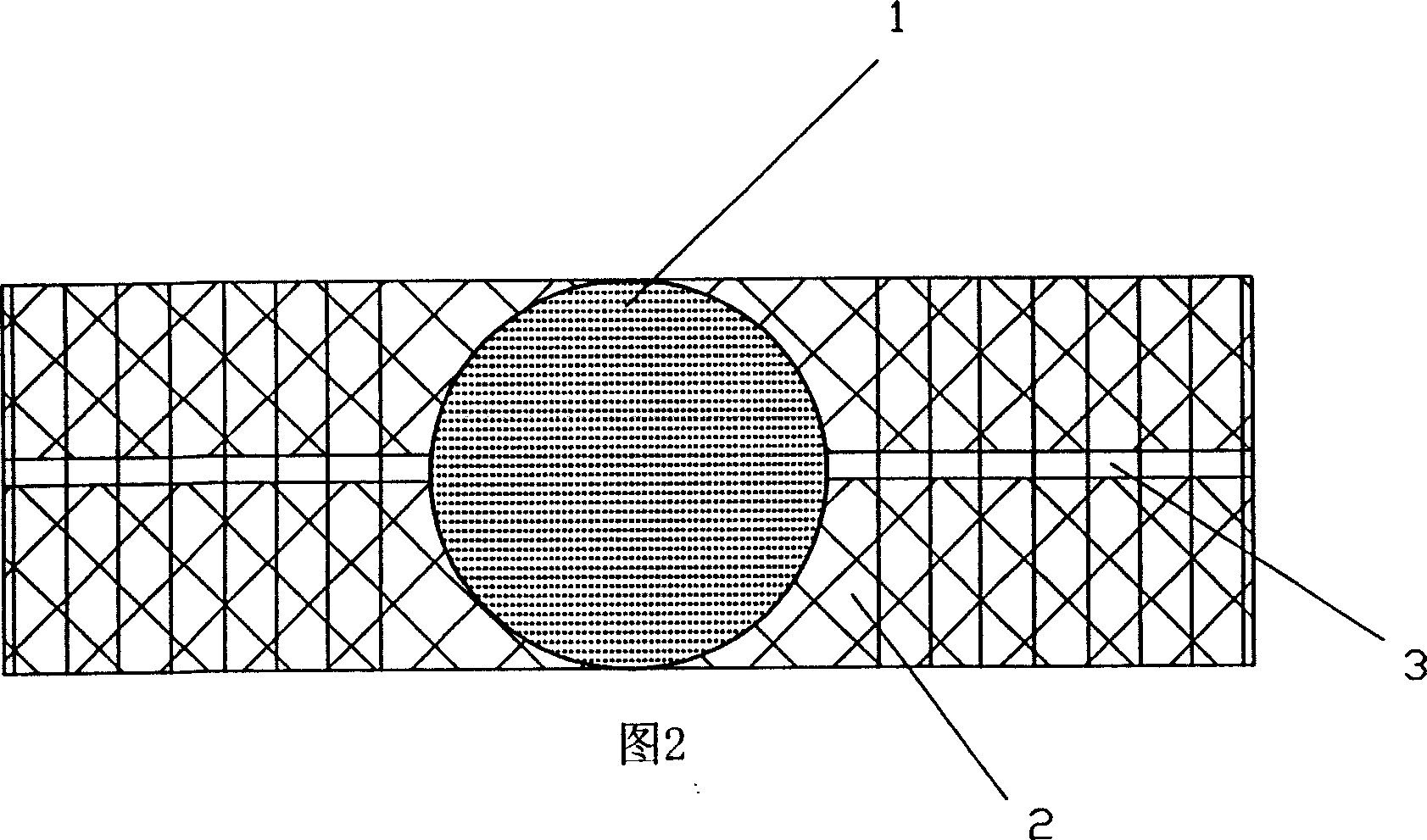

Far infrared heating wire and preparing method

A heating line and far-infrared technology, applied in the direction of heating element material, heating element shape, coating, etc., can solve the problems that far-infrared wavelength is not completely suitable for human body absorption, treatment is limited to local areas, and thermal efficiency is not enough, etc., to achieve heating effect. Good, good insulation, good for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The core wire is composed of 4 bundles of 12K polyacrylonitrile carbon fiber monofilaments; the far-infrared heating is prepared according to the above preparation method. In the first step, the glycerin coating solution used is formulated with 25% glycerin, 10% ethanol, and 65% pure water. The part of the core wire immersed in the glycerin coating liquid passes through at a speed of 0.5 meters per minute, dried at 90°C, and stays in an oven for 3 minutes; then thickens the polyethylene protective cover of 0.45mm.

Embodiment 2

[0023] The core wire is composed of 6 bundles of 12K polyacrylonitrile carbon fiber monofilament; the far-infrared heating is prepared according to the above-mentioned preparation method. In the first step, the glycerin coating solution used is formulated with glycerin 35%, ethanol 10%, and purified water 55%. The part of the core wire immersed in the glycerin coating solution passes through at a speed of 1 meter per minute, is dried at 110°C, stays in an oven for 3 minutes, and then thickens to a polyethylene protective cover of 0.80 mm.

Embodiment 3

[0025] The core wire is composed of 12K polyacrylonitrile carbon fiber monofilament. The far-infrared heating is prepared according to the above preparation method. In the first step, the glycerin coating solution used is made up of 30% glycerin, 15% ethanol, and 55% pure water; The part of the thread immersed in the glycerin coating liquid passes through at a speed of 0.7 meters per minute; it is dried at 100°C and stays in an oven for 3 minutes; then the protective cover of the filament non-woven fabric is widened by 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com