Method of comprehensive utilizing schisandra fruit

A technology of Schisandra chinensis and extraction method, which is applied in chemical instruments and methods, drug combinations, pharmaceutical formulas, etc., and can solve the problem of unutilized active ingredient lignans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

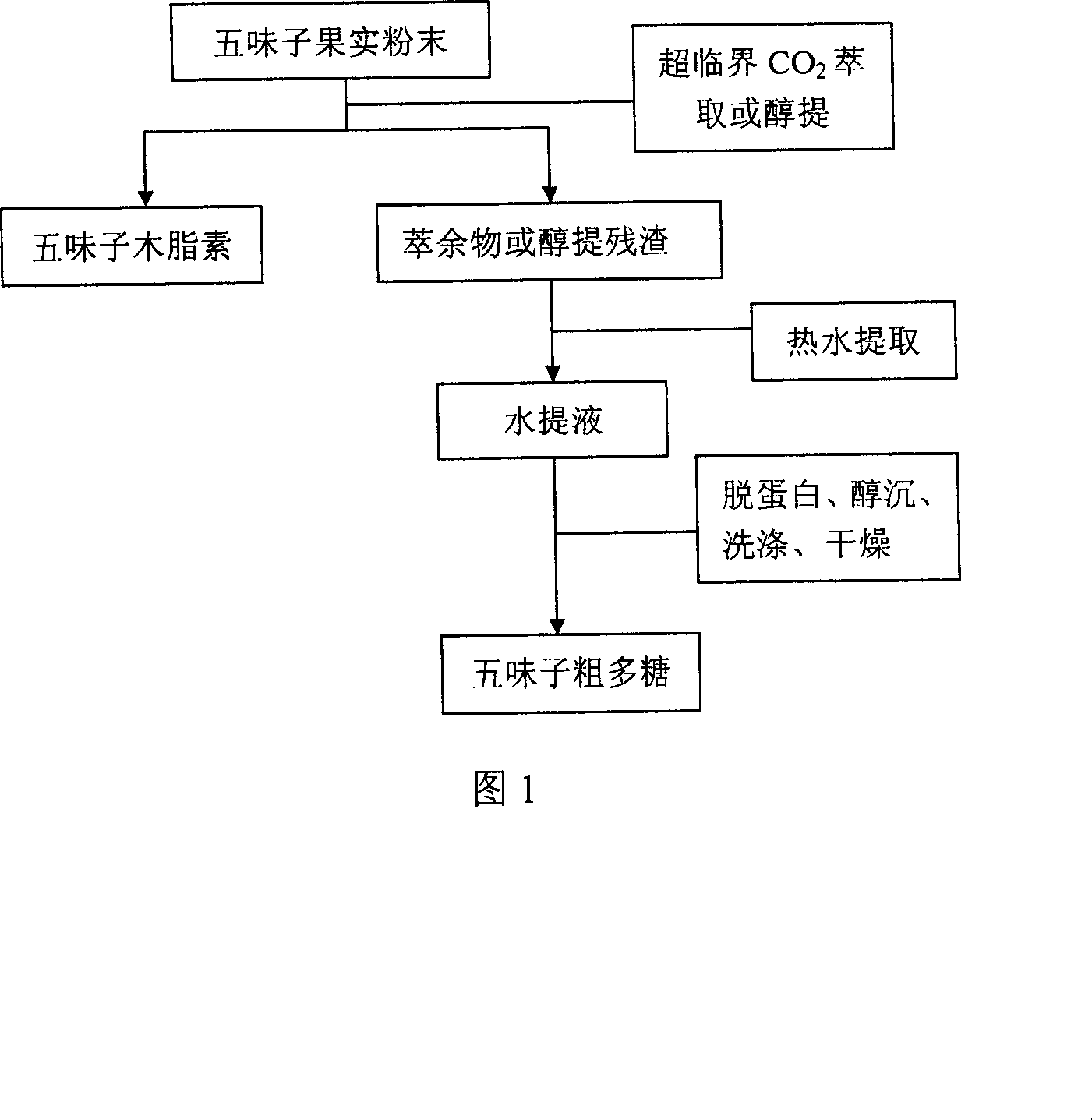

Method used

Image

Examples

Embodiment 1

[0020] Take southern Schisandra fruit powder as raw material, weigh 20g and put it into supercritical CO 2 Extraction unit, in CO 2 Static extraction for 5 hours at a pressure of 25MPa and an extraction temperature of 35°C; then at an extraction pressure of 25MPa, an extraction temperature of 35°C, 2 Under the condition of flow rate 2L / min, dynamic extraction was carried out for 3 hours, and the separation temperature was 60°C, and the extract and raffinate residue of Schisandra chinensis were collected. Schisandra chinensis was used as reference substance, chromotropic acid was used for color development, and the lignan content was determined by spectrophotometry. The result was that the total lignan extraction rate in the southern Schisandra extract was 95.5%, and the lignan content was 9.2%.

[0021] Southern Schisandra supercritical CO 2 The residue of the raffinate is used as the raw material, the ratio of material to liquid is 1:20 (w / v, g / mL), the boiling water is ref...

Embodiment 2

[0023] With Schisandra chinensis fruit powder as raw material, operate in the same way as in Example 1. Using Schisandra A as the reference substance, chromotropic acid was used for color development, and the lignan content was determined by spectrophotometry. The result was that the total lignan extraction rate in the Schisandra chinensis extract was 93.2%, and the lignan content was 13.0%. Schisandra supercritical CO 2 The crude polysaccharide yield in the raffinate residue was 19.6%, and the polysaccharide content measured by the phenol-sulfuric acid method was 28.5%.

Embodiment 3

[0025] Using southern Schisandra fruit powder as raw material, solid-liquid ratio 1:10 (w / v, g / mL), reflux of 60% ethanol solution (v / v) to extract lignans in Schisandra chinensis, extract twice, each time for 2 hours . Filtrate, concentrate the filtrate in vacuo to obtain the extract extract, and collect the alcohol extraction residue. Taking Schisandra A as reference substance, chromotropic acid was used to develop color, and the content of lignans was determined by spectrophotometry. The result was that the extraction rate of total lignans in the extract of Schisandra chinensis was 70.8%, and the content of lignans was 3.6%.

[0026] The residue after extracting lignans from Schisandra chinensis with 60% ethanol is used as raw material, the ratio of solid to liquid is 1:20 (w / v, g / mL), the boiling water is extracted in the same flow for 6 hours, extracted once, filtered, and the filtrate is concentrated under reduced pressure To 1 / 3 of the original volume, the concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com