Maintenance sealing structure

A technology for overhauling seals and gaskets, which is applied in the direction of engine seals, bellows, mechanical equipment, etc., can solve the problems of not fully exerting the sealing function, and achieve the effects of reducing the number of parts, good sealing performance, and easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

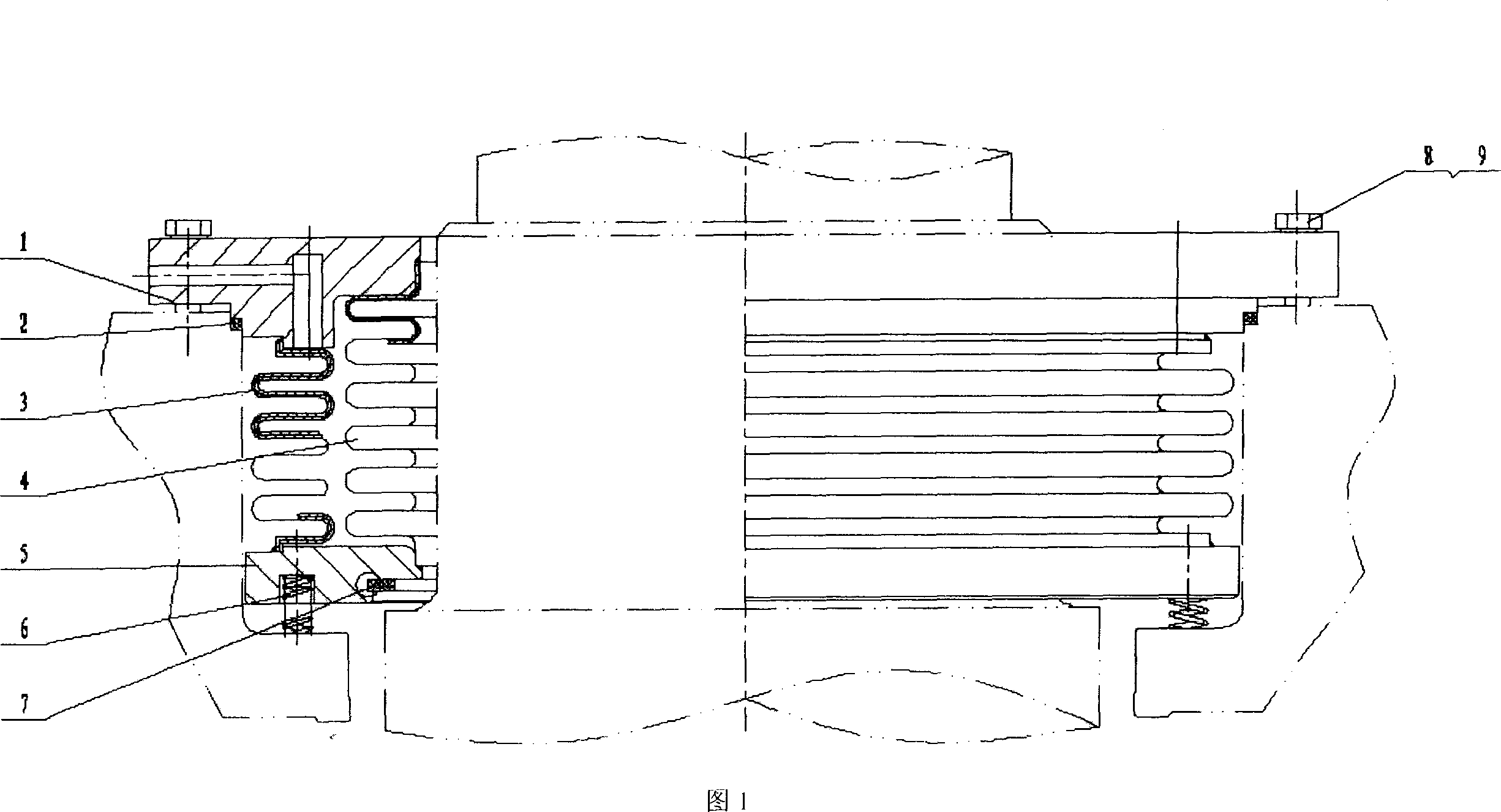

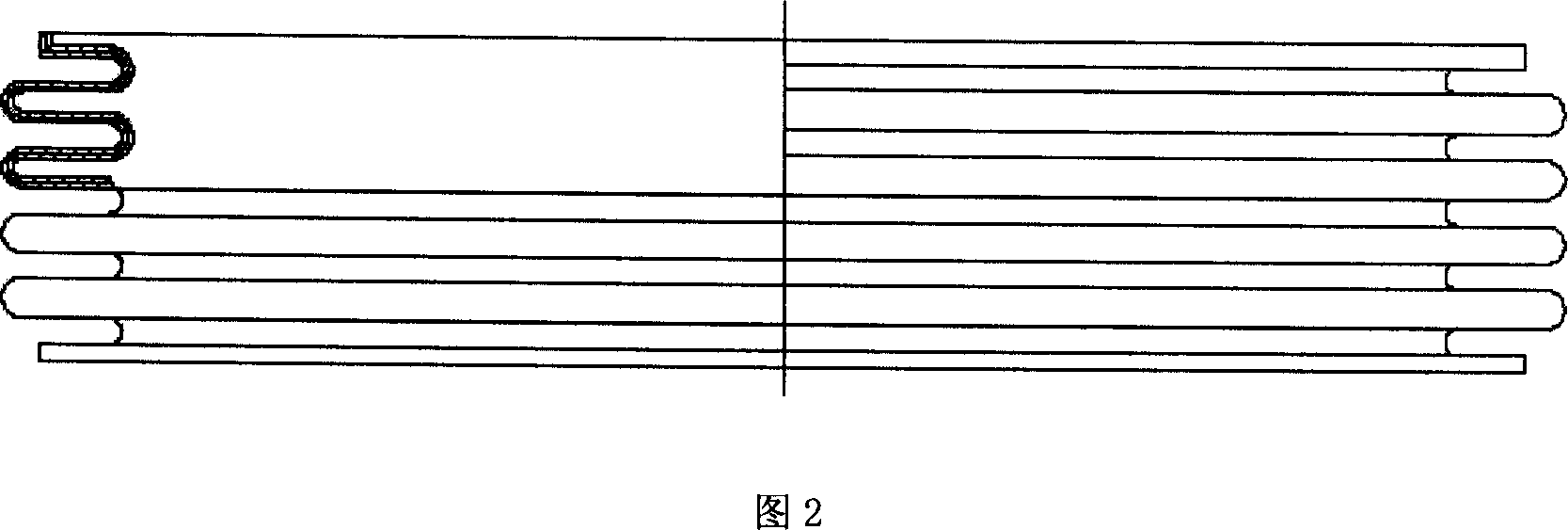

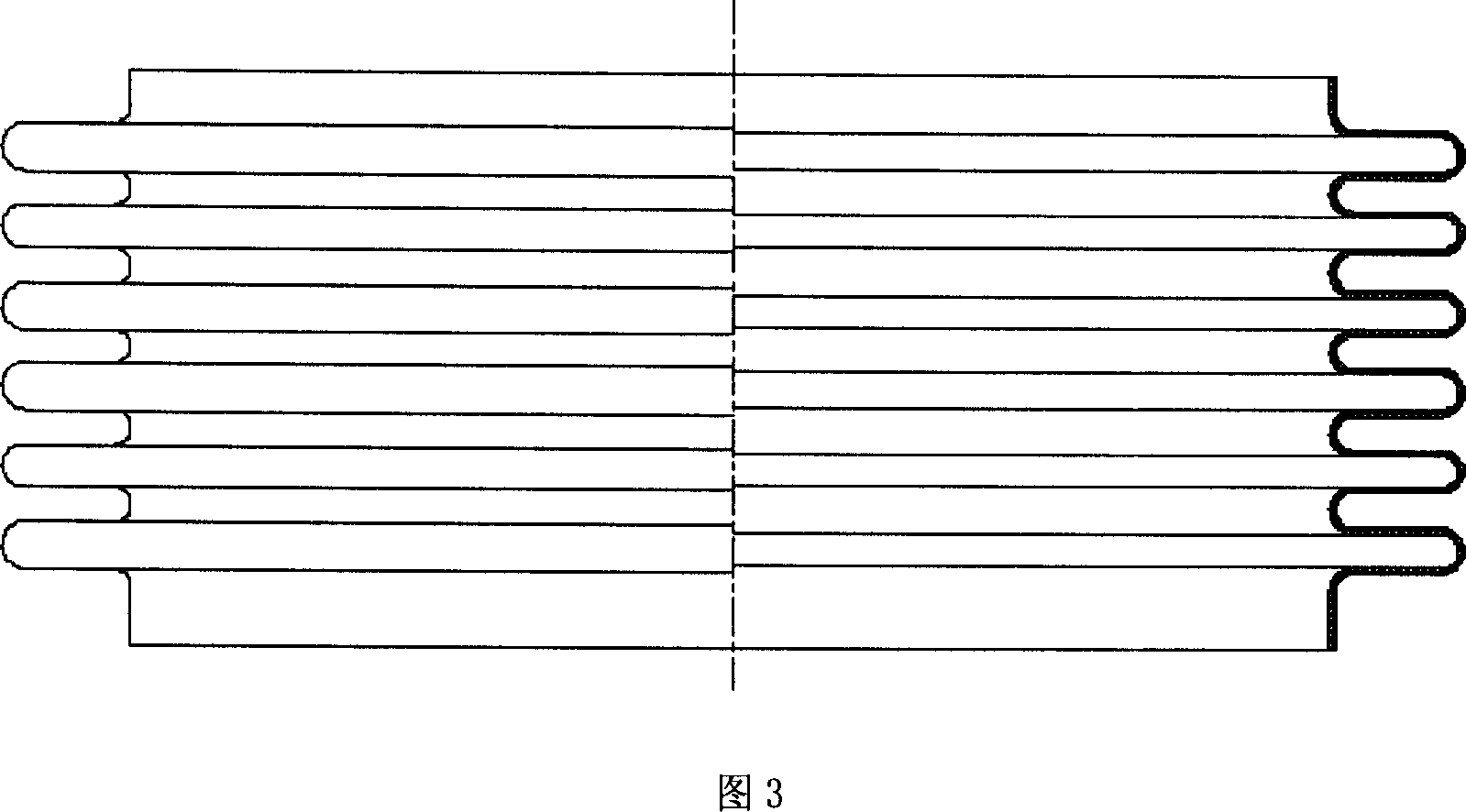

[0021] Combined with Figure 1 and Figure 2-8 at the same time, the composition of the maintenance sealing structure includes bellows, the bellows include working bellows 3 and sealing bellows 4, and the two ends of the working and sealing bellows are respectively connected by sub-arc welding On the supporting flange 1 and the moving flange 5, a sealing ring 7 is installed on the moving flange, the sealing ring is made of polytetrafluoroethylene, and the supporting flange is installed on the On the bearing support, there is a gas transmission channel communicated with the sealing chamber between the working bellows and the sealing bellows on the supporting flange. A support flange gasket 2 is arranged between the support flange and the bearing support. Have spring 6 on the mobile flange. There are two gas transmission channels, which are symmetrically distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com