Optical recording medium

An optical recording medium and recording medium technology, applied in the direction of optical recording carrier, temperature recording method, recording carrier material, etc., can solve the problems of reduced recording characteristics, inability to obtain sensitivity, and unsatisfactory levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

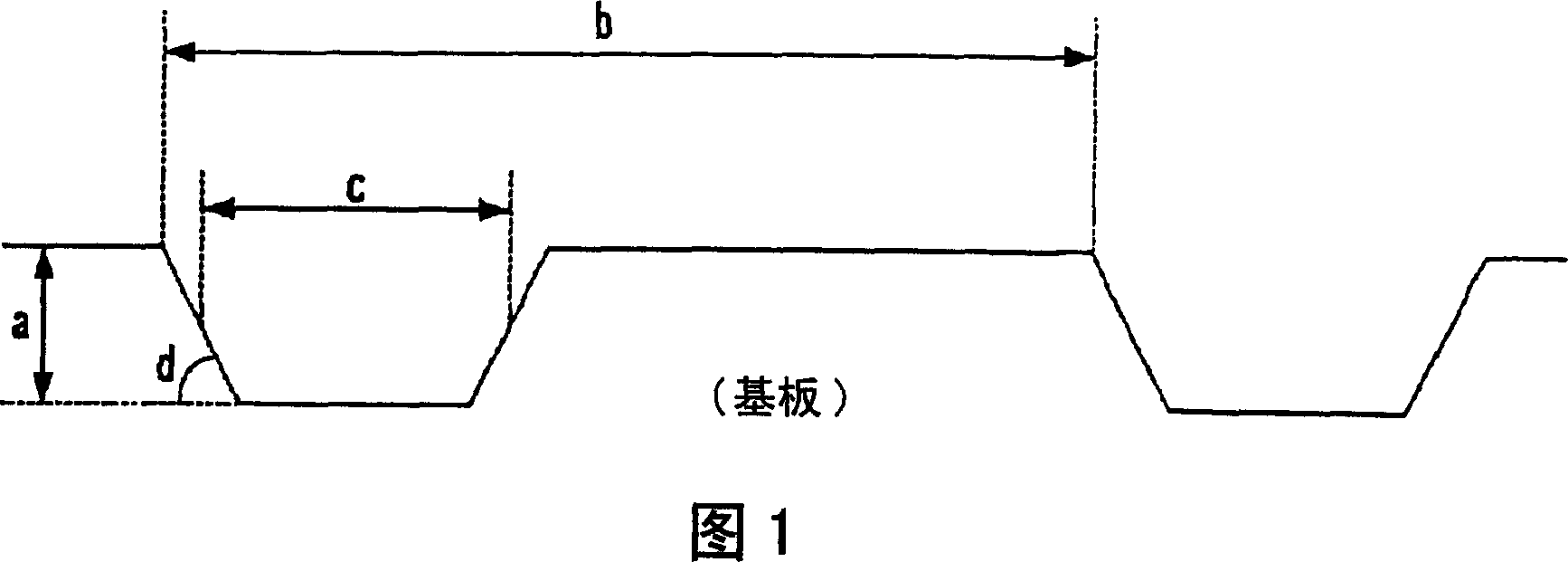

[0145] Polycarbonate resin (manufactured by Teijin Chemicals Co., Ltd., trade name Panrit AD5503) was injection-molded to have spiral grooves (depth 100nm, half-value width 120nm, track pitch 0.3μm) and thickness 1.1mm, diameter 120mm substrate. Then, a reflective layer made of an Ag film having a film thickness of 100 nm was formed by a sputtering method on the surface of the substrate having the grooves.

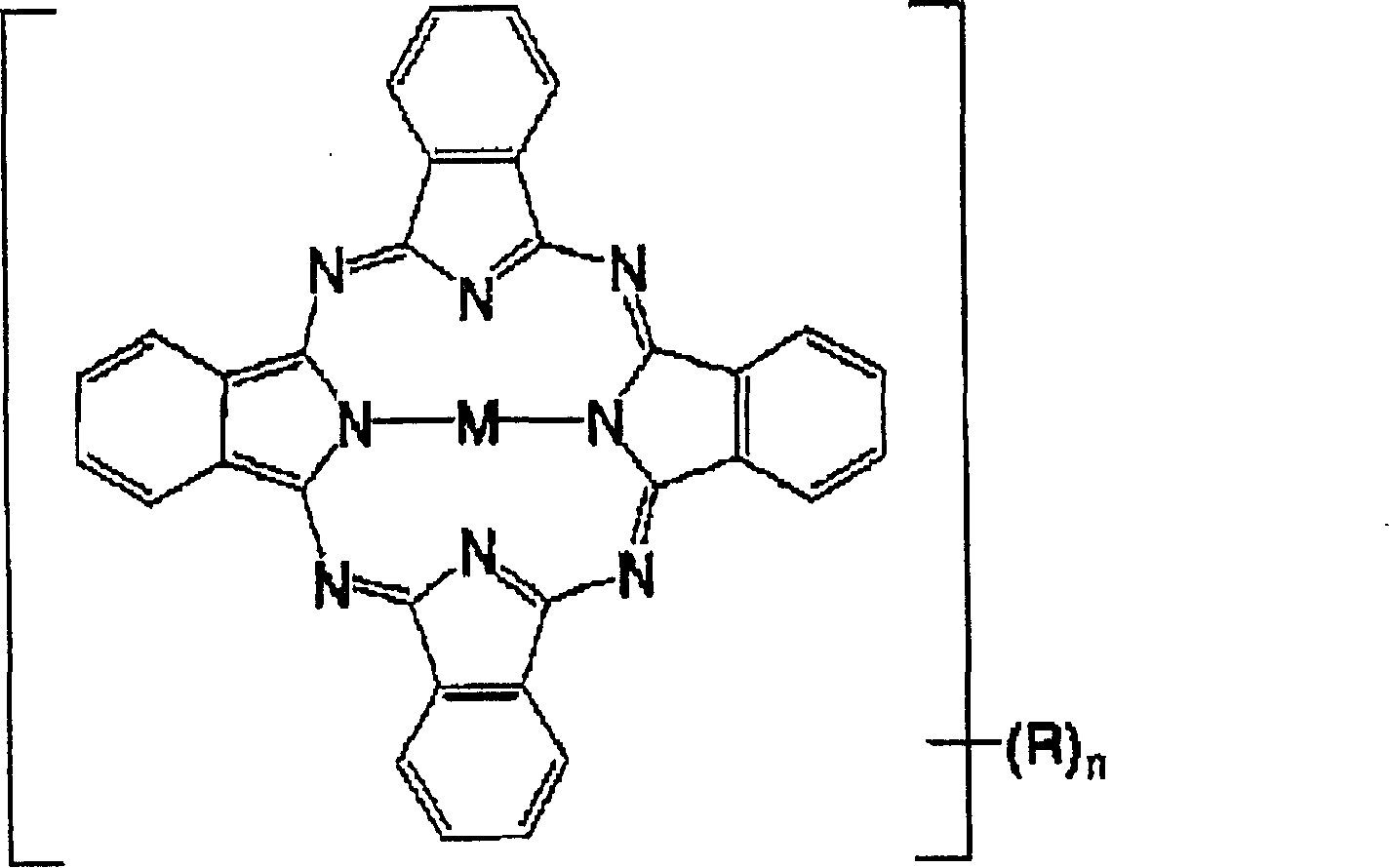

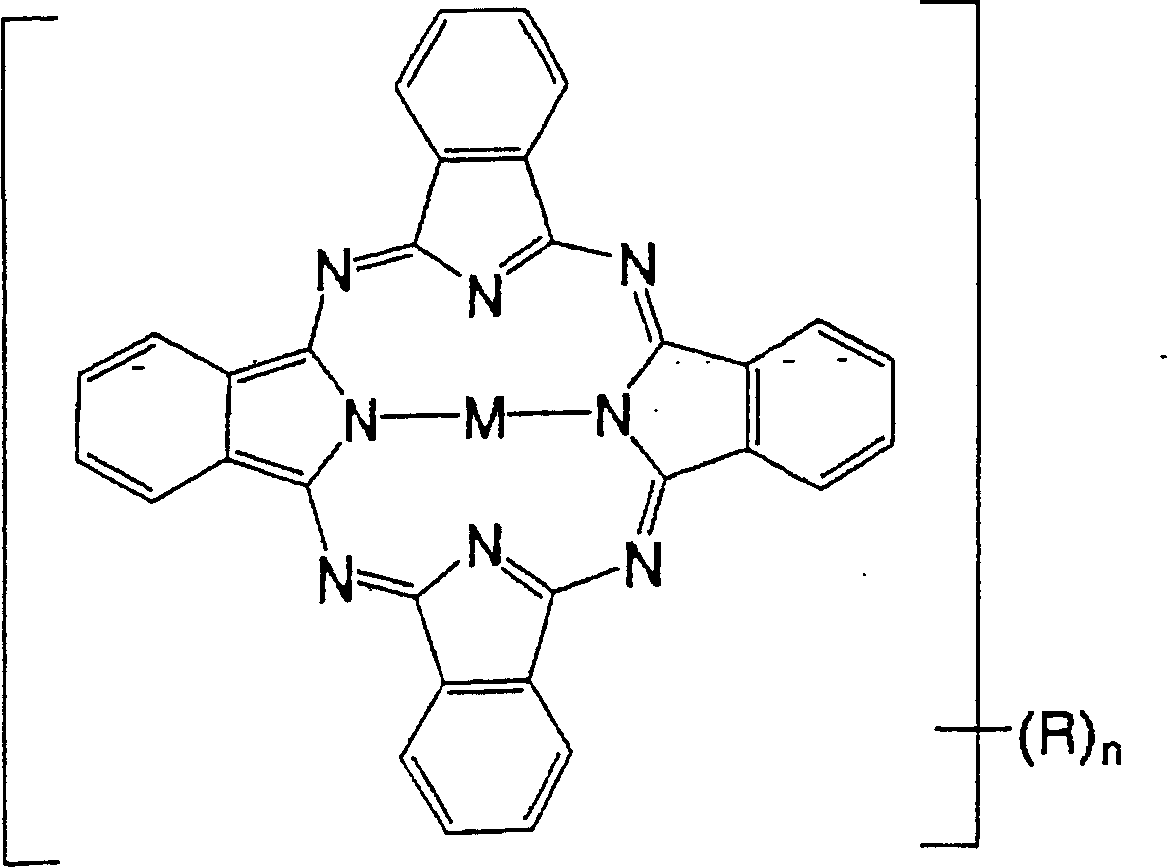

[0146] Mix 2 g of phthalocyanine organic compound A (manufactured by Cibaspesiaritie Chemical, Orazol Blue-GN) having maximum absorption at 340 nm and 680 nm in 100 ml of 2,2,3,3-tetrafluoropropanol, and perform ultrasonic treatment for 2 hours to make dissolved to prepare an organic coating solution.

[0147] On the Ag reflective layer, the above-mentioned organic coating liquid was applied while changing the rotation speed from 300 rpm to 4000 rpm under the condition of 23°C·50%RH by the spin coating method, and then sprayed at 23°C·50%RH The temperature was maintained f...

Embodiment 2

[0151] In the preparation of the sample in Example 1, a sample was produced in the same manner as in Example 1, except that the organic substance was replaced with phthalocyanine-based organic substance B (manufactured by Cibaspesiaritie Chemical, Super Green) having maximum absorption at 330 nm and 730 nm.

Embodiment 3

[0153] In the preparation of the sample in Example 1, a sample was produced in the same manner as in Example 1, except that the organic substance was replaced with a phthalocyanine-based organic substance C (manufactured by Wako Pure Chemical Industries, Ltd., FOM0561) having maximum absorption at 340 nm and 680 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com