Filter media

A filter medium and filter technology, which is applied in the fields of filtration and separation, adsorption water/sewage treatment, chemical instruments and methods, etc., and can solve problems such as inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] By taking 100 grams of PAC (from Active Carbon company in India) and 30 grams of MFR is about 0, bulk density is 0.22g / cm 3 Carbon blocks were prepared from ultra-high molecular weight polyethylene (from Asahi, Japan). 6.5 wt% of the particles in the PAC passed through the 200 mesh screen and 98% of the particles passed through the 50 mesh screen. The powders were mixed in a screw mixer for 30 minutes and then transferred to molds. Then, the mold was vibrated on a vibrator for 5 minutes, after which it was subjected to 10kg / cm 2 hydraulic pressure. Thereafter, the mold was heated to 260°C for 150 minutes and then cooled.

Embodiment 2 and 3

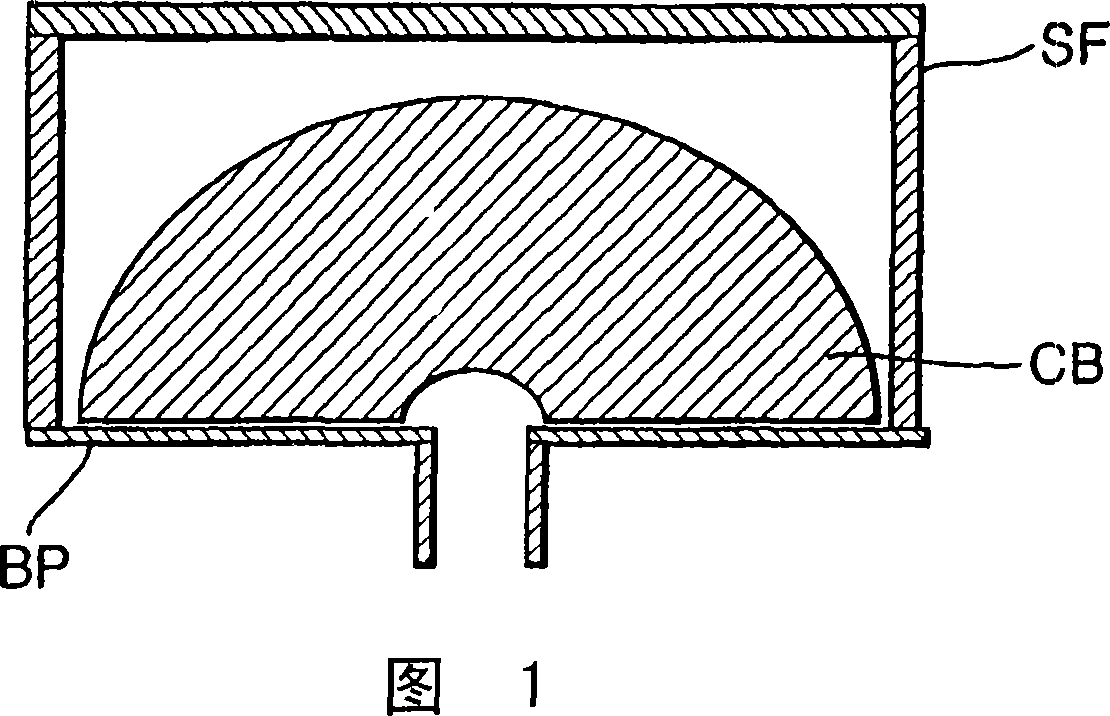

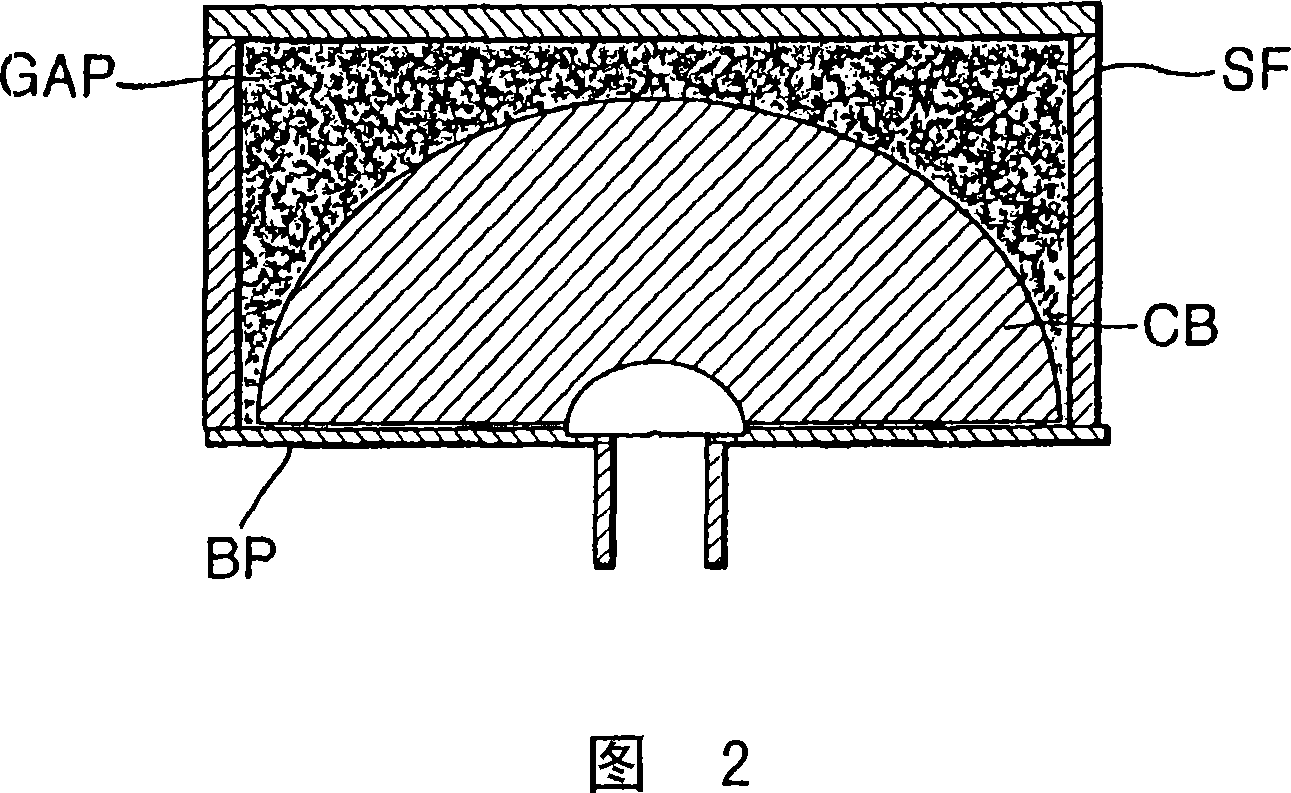

[0130] Test water was prepared containing 15 mg / liter fine Arizona test dust and additionally contained 0.47 ppm dissolved aluminum cations and 0.4 ppm dissolved iron cations. This test water is filtered through the water filter (embodiment 2) of Figure-1 and the water filter (embodiment 3) of Figure-2, and the pressure head is constant at 160mm. The flow rates obtained during the duration of use of the filters are summarized in Table-3. Satisfactory filtered water quality was obtained with both water filters.

[0131] Total volume of water passed, liters

[0132] The data in Table-3 shows that a high output flow rate of filtered water was obtained using the water filter (Fig.-1) comprising the carbon block filter media of the present invention. Increased water flow rate was obtained using a water filter comprising granular sorbent particles and carbon blocks according to a preferred aspect of the present invention (Fig.-2).

Embodiment 4 and 5

[0134] A further highly contaminated fatigue test water was prepared containing 130 mg per liter of fine Arizona test dust, in addition to 4.7 ppm dissolved aluminum cations and 4 ppm dissolved iron cations. This test water is filtered through the water filter (embodiment 2) of Figure-1 and the water filter (embodiment 3) of Figure-2, and the pressure head is constant at 160mm. The flow rates obtained during the duration of use of the filters are summarized in Table-4. Satisfactory filtered water quality was obtained with both water filters.

[0135] Total volume of water passed, liters

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com