Non-conductive material water-supply pipeline leak-detection method

A technology of non-conductive materials and water supply pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as uncertainties and complex terrain conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

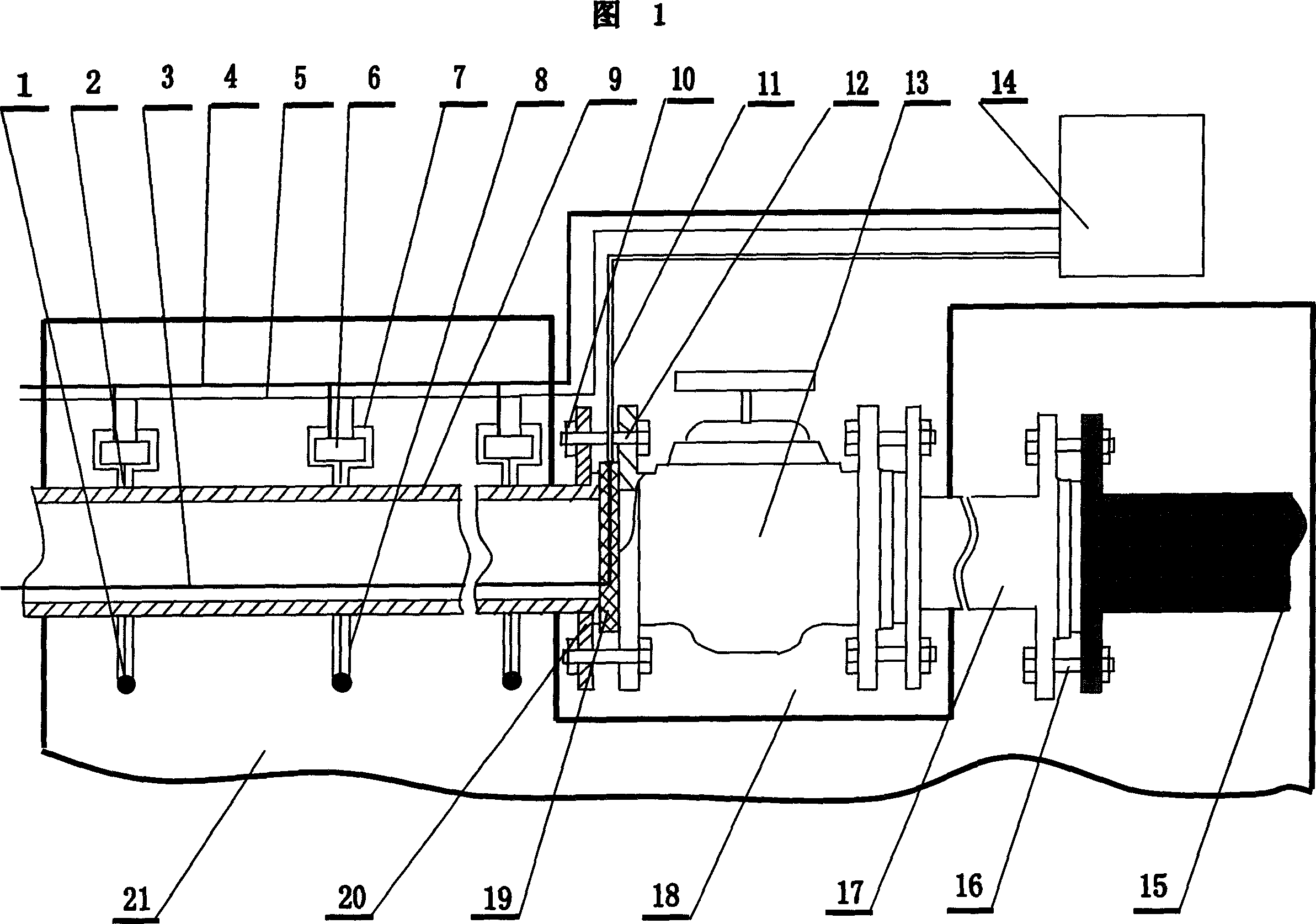

[0008] 1 in Figure 1 is the output line connector, which is one of the electrodes outside the tube wall, 2 is the receiver output line, 3 is the return line, 4 is the power line, 5 is the pulse line, 6 is the patrol pulse receiver, 7 8 is the protective cover of the receiver, 8 is the output line protection rod, 8 is the water pipe of non-conductive material, 10 is the nut, 11 is the insulating lead wire, 12 is the bolt, 13 is the outer wall insulation valve, 14 is the electric measuring instrument, 15 is Water inlet iron pipe, 16 is the connecting bolt of iron pipe and non-conductive material pipe, 17 is the non-conductive material water pipe without electrodes inside and outside the pipe, 18 is the valve well, 19 is the insulating packing ring for putting the wire inside, 20 is the chain, 21 It's dirt. 1 in the figure is used as the output line connector of a conductive pole and a detection head outside the non-conductive material water supply pipeline. Such output line conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com