Electrical isolating method for silicon carboride device

An electrical isolation, silicon carbide technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as difficult processing and low yield, reduce production costs, improve performance and yield, and simplify manufacturing processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

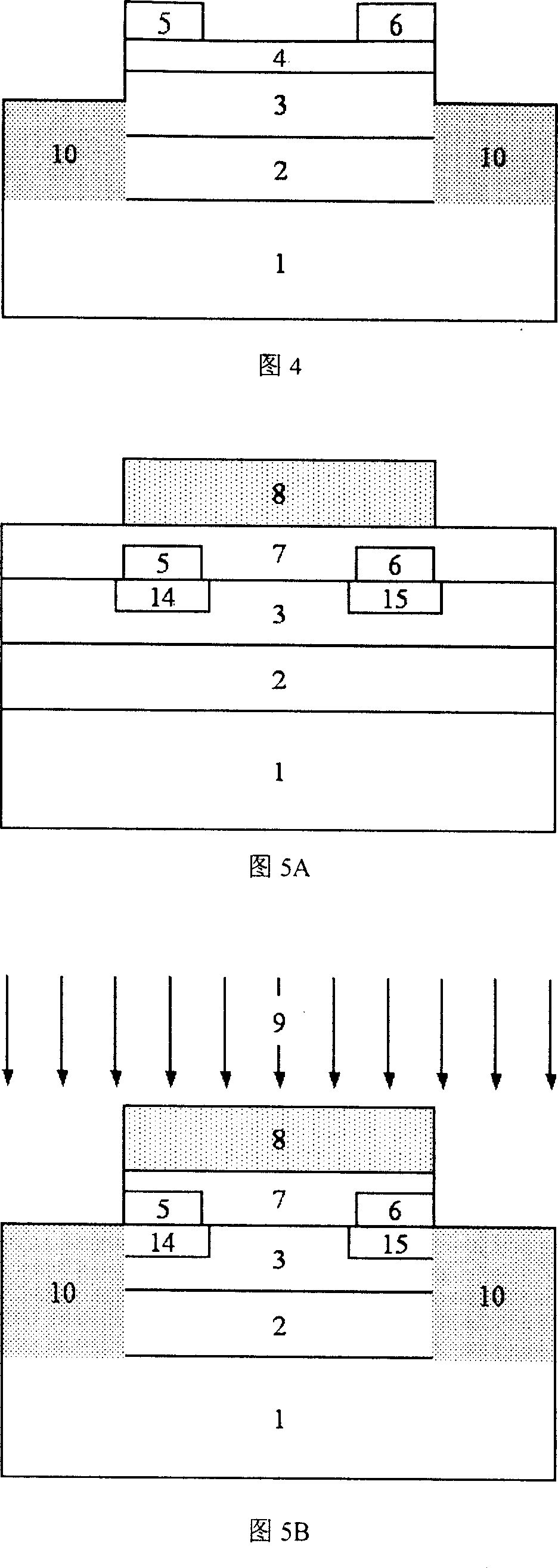

[0044] As shown in Figures 5A-5C.

[0045] As shown in FIG. 5A, a first ohmic contact region 5 is formed on the selectively doped region 14 of the SiC MESFET as a source electrode, and a second ohmic contact region 5 is formed on the selectively doped region 15 which is 2 microns to 5 microns away from the first ohmic contact region 5. Two ohmic contact regions 6 serve as drain electrodes. The selectively doped regions 14 and 15 are obtained by implanting nitrogen or phosphorus ions and annealing at high temperature. Preferably, a sacrificial oxide film 7 is deposited on the surface of the SiC MESFET material with a thickness of 50 nm to 500 nm. The sacrificial oxide film includes but is not limited to silicon oxide (SiO 2 ) and silicon oxynitride (SiON), the deposition methods include but not limited to sputtering, electron beam evaporation, plasma enhanced chemical vapor deposition (PECVD); the SiC MESFET material and the surface of the device do not need to be processed by...

Embodiment 2

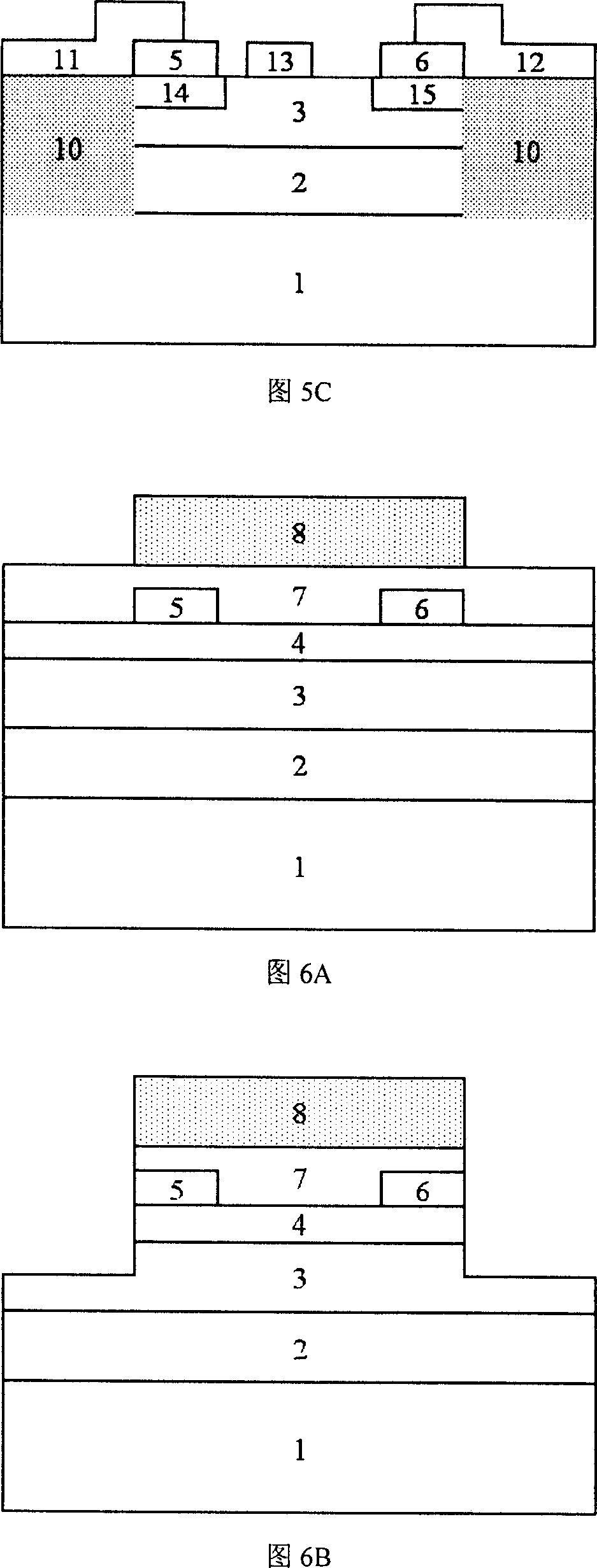

[0050] As shown in Figures 6A-6D.

[0051] As shown in FIG. 6A, a first ohmic contact region 5 is formed on the ohmic contact layer 4 of the SiC MESFET as a source electrode, and a second The ohmic contact region 6 serves as a drain electrode. Preferably, a sacrificial oxide layer 7 is deposited on the surface of the SiC MESFET material with a thickness of 50 nm to 500 nm. The sacrificial oxide dielectric layer includes but is not limited to silicon oxide (SiO 2 ) and silicon oxynitride (SiON), the deposition methods include but not limited to sputtering, electron beam evaporation, plasma enhanced chemical vapor deposition (PECVD); the SiC MESFET material and device surface do not need to be processed with a photosensitive film 8 The place for etching and ion implantation is protected, and the preferred thickness of the photosensitive film 8 is 2 microns to 8 microns.

[0052] As shown in FIG. 6B, using the photosensitive film 8 as an etching mask, a shallow groove is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap