Electromechanical integrated machine tool chuck directly constituted of external rotor rotating electric machine

A technology of rotating electrical machines and external rotors, applied to synchronous motors with stationary armatures and rotating magnets, chucks, electromechanical devices, etc., can solve problems such as raw materials, energy, capital, and time consumption, and achieve international competitiveness , Simple structure, saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

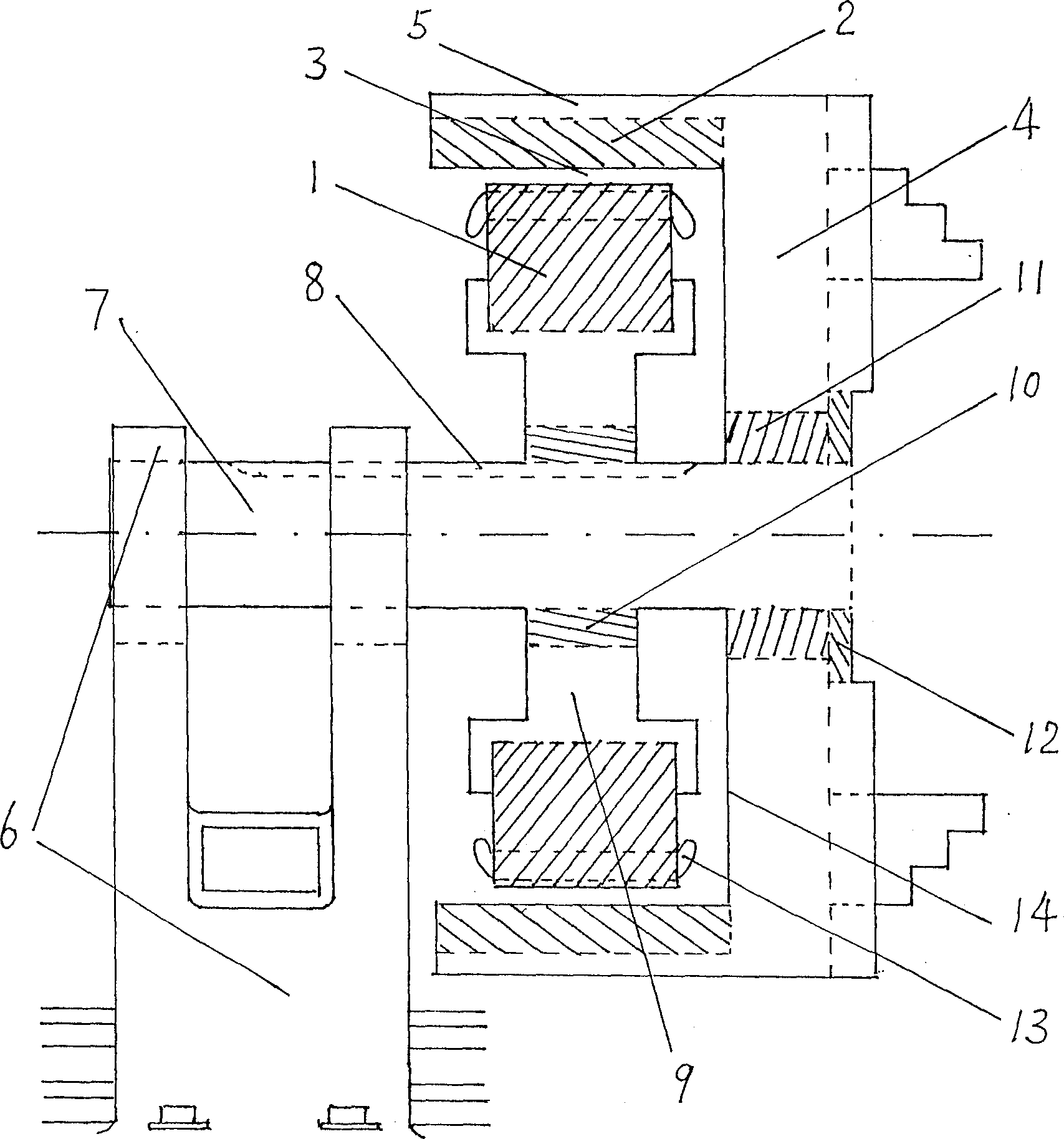

[0009] The specific implementation manners of the invention of the present application will be described in further detail below in conjunction with the accompanying drawings.

[0010]What is shown in the accompanying drawings is an embodiment of the invention of the present application. People can use traditional mechanical connection installation methods such as pins, keys, screws, etc., to firmly inlay and install the secondary rotor ring body 2 of the outer rotor rotary motor on the extension part 5 of the outer circular shell edge of the chuck 4 of the horizontal machine tool. in. The machine tool chuck 4 is installed and fixed on the main shaft 7 through the bearing 11 or the bearing bush 11, and can rotate in any direction. The inner end surface of the bearing 11 or the bearing bush 11 is protected by a spindle step, or a circular gasket, or an inner end cover; the outer end surface is protected by an outer end cover 12 . The main shaft 7 is horizontally installed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com