Fiber-reinforced resin composition and molded body thereof

A composition and molding technology, which is applied in the field of fiber-reinforced resin compositions and moldings obtained therefrom, and can solve problems such as increased density, increased ash content, and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] After mixing (dry mixing) each material shown in the following Table 1, it was charged into a twin-screw extruder (manufactured by Toshiba Machine, TEM-35B, cylinder temperature: 200° C., screw rotation speed: 300 rpm) from a top feeder , and melt-kneaded to obtain a fiber-reinforced resin composition.

Embodiment 2~4、 comparative example 1~3

[0071] A fiber-reinforced resin composition was prepared in the same manner as in Example 1 except that the component composition was changed to that shown in Table 1 below.

[0072]

[0073]The fiber-reinforced resin compositions prepared in Examples 1 to 4 and Comparative Examples 1 to 3 were molded according to the following method, and various physical properties of the obtained molded products (test pieces) were determined according to the following method. The obtained results are shown in Table 1 below.

[0074] (1) Curvature (%):

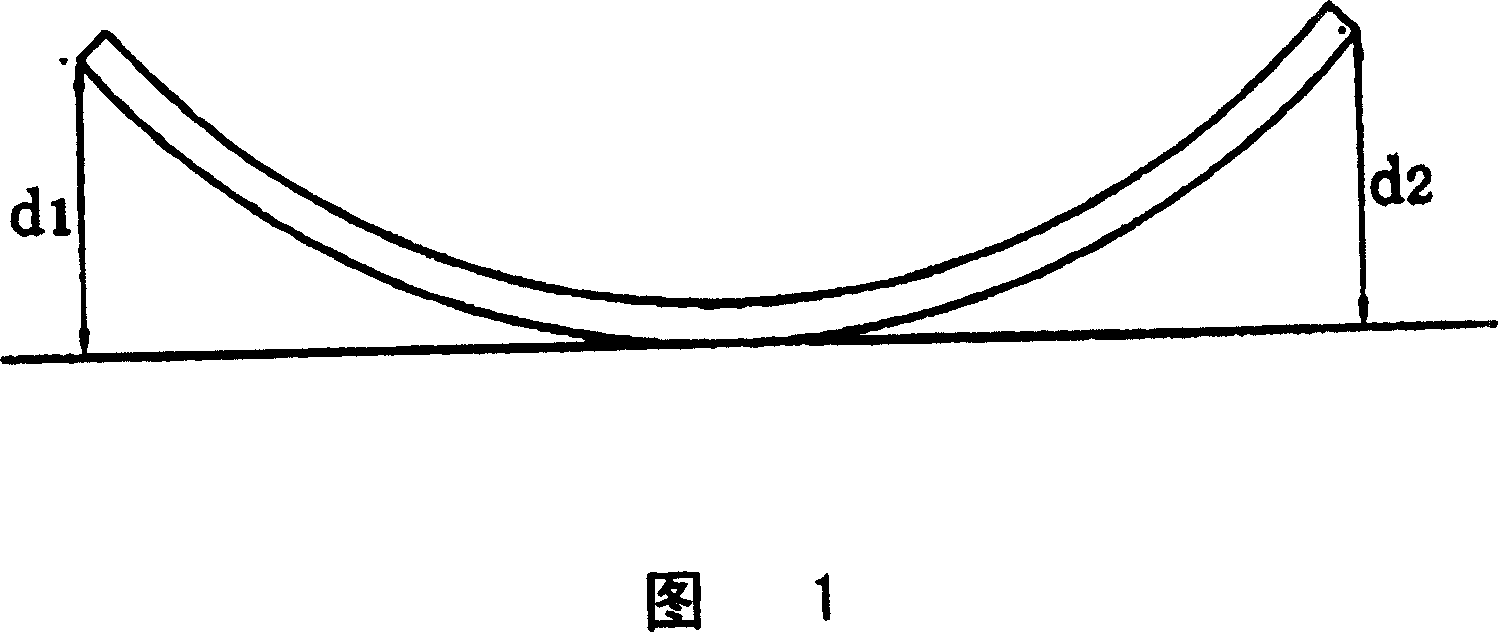

[0075] Through injection molding, it is formed into a circular plate with a diameter of 150mm and a thickness of 2.5mm. After adjusting the state at 23°C for 48 hours, as shown in Figure 1, obtain d 1 and d 2 , the curvature is calculated from the following formula.

[0076] Curvature (%) = {(d 1 +d 2 ) / (2×140)}×100

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com