Convenient meat and rice flour noodle and its processing method

A processing method and technology of vermicelli, applied in food preparation, food shaping, food science, etc., can solve problems such as unfavorable food production, waste of food resources, and limited utilization of milled rice, so as to improve income generation and planting enthusiasm. The effect of increasing conversion rate and huge commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

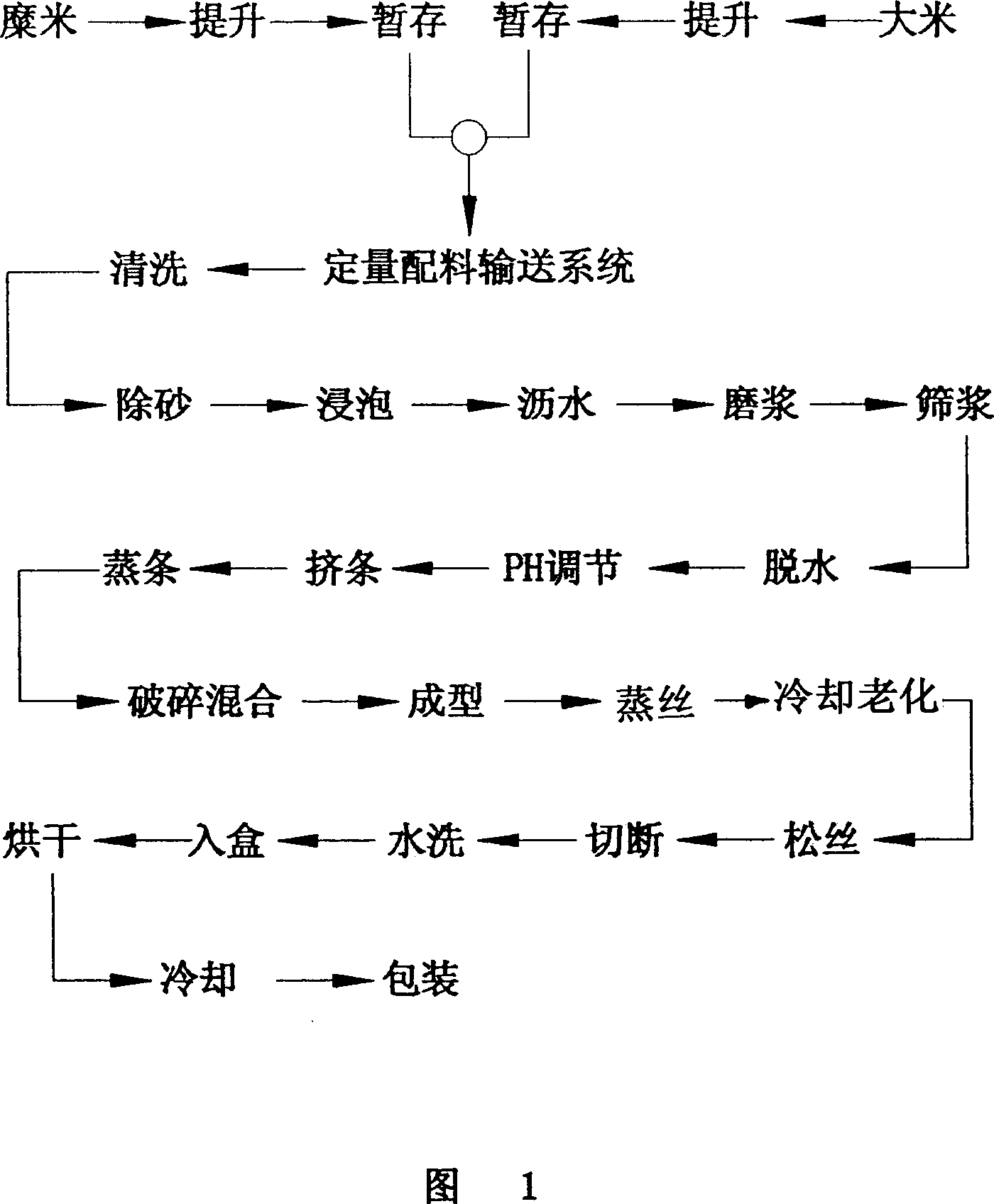

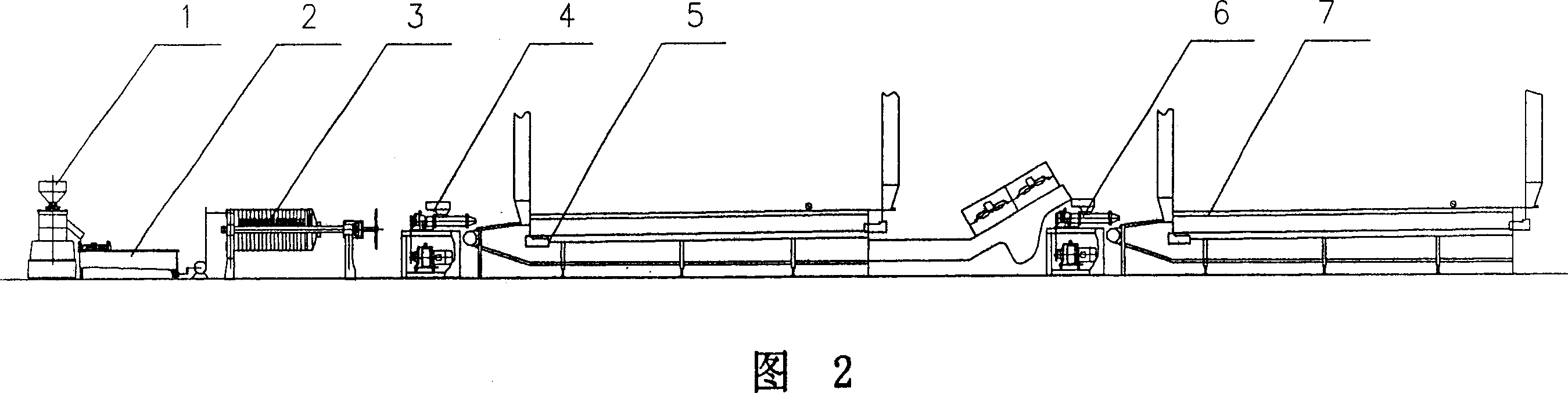

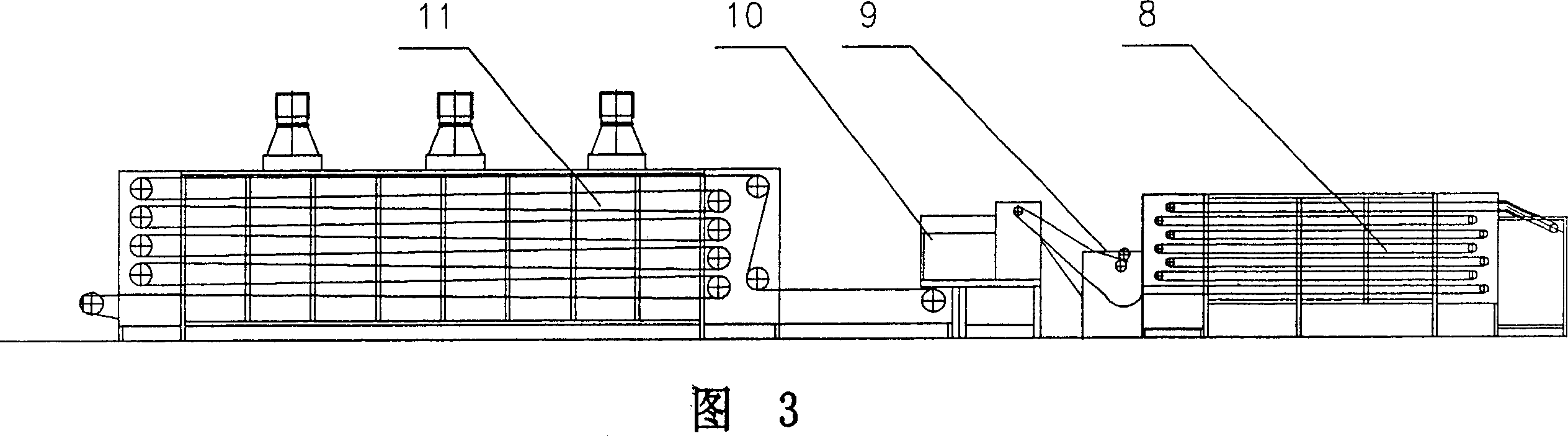

[0033] With reference to Fig. 1, Fig. 2 and Fig. 3, the present embodiment comprises the following steps:

[0034] Weigh 20Kg milled rice and 5Kg rice with pounds, mix them according to the ratio (4:1), wash them with water to remove impurities, put them in a stainless steel container and soak them in water at room temperature for 3-4 hours, the amount of water is controlled according to the surface of the material All soaked in water shall prevail; then pour the soaked mixed raw materials into the refiner 1 for grinding and pulping, the particle size is between 100-140 mesh and the concentration of the slurry is controlled at 18-22 wave magnesium; Then the vibrating separator 2 is used to separate the coarse fiber and larger impurities in the slurry. The rice milk is sent into the filter press 3 with a screw pump to remove part of the moisture in the rice milk, and the water content of the dehydrated rice flour is preferably between 38% and 40%. The broken and dehydrated ric...

specific Embodiment 2

[0037] The characteristics of the present embodiment are: the weight ratio of milled rice and rice is 6:1.

[0038] In the processing method, the temperature control of fermentation and automatic pH value adjustment in step 4) is 27-35°C, the humidity is 65%, and the fermentation time is 4 hours; the specific process conditions for steaming flour twice in step 5) are as follows: squeezed The strips are directly steamed once, steamed with 0.1Mpa saturated steam for 15 minutes, so that the starch in the vermicelli reaches 75%, and the steamed vermicelli is crushed and cooled to 30°C to 45°C for molding; the formed vermicelli is directly Carry out secondary steaming, and steam 8 minutes with the saturated steam of 0.1Mpa, starch starch α is made to reach more than 95%; Step 6) in the aging time preferred range is 1.5 hours; Step 7) in the drying temperature preferred range control is 40 ~50°C, the preferred range of time is 2 hours. All the other are with embodiment 1.

specific Embodiment 3

[0039] The characteristics of the present embodiment are: the weight ratio of milled rice and rice is 8:1.

[0040]In the processing method, the temperature control of fermentation and automatic pH value adjustment in step 4) is 27-35° C., the humidity is 75%, and the fermentation time is 6 hours; the specific process conditions for steaming flour twice in step 5) are as follows: The strips are directly steamed once, steamed with 0.2Mpa saturated steam for 5 minutes, so that the starch in the vermicelli reaches 85%, and the steamed vermicelli is broken and cooled to 30°C to 45°C for molding; the formed vermicelli is directly Carry out secondary steaming, steam 6 minutes with the saturated steam of 0.2Mpa, make starch starch α reach more than 95%; Step 6) in the aging time preferred range is 2.5 hours; Step 7) in the drying temperature preferred range control is 40 ~50°C, the preferred time range is 3 hours.

[0041] In other embodiments of the present invention, the weight ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com