New method of preparing tert-butyl phenol by alkylation of phenol and isobutene

A technology of alkylation reaction and tert-butylphenol, which is applied in the field of reaction between phenols and isobutylene, can solve the problems of cost reduction, failure to achieve, increase equipment capital investment, etc., and achieve the goal of reducing production cost, simple equipment, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Below is to add Venturi injector and material liquid circulation pump and not add the device response data contrast of Venturi injector: Embodiment 1: (do not add the device response data of Venturi injector)

[0014] Add p-cresol 54g and concentrated sulfuric acid as a catalyst in a 250mL four-necked reaction flask with a stirring and condensing device, and the dosage is 1.35g. Raise the temperature to 60-65°C and feed isobutene gas. The isobutene in the exhaust gas is released. During the reaction, it is monitored by gas chromatography. When the BHT content reaches more than 90%, the isobutene is stopped. The gas flow rate is 150ml / min, and the time is 3.5h. The amount of isobutene used in the experiment is 78g. 30% of the isobutene is released as tail gas, and the utilization rate is 70%.

Embodiment 2

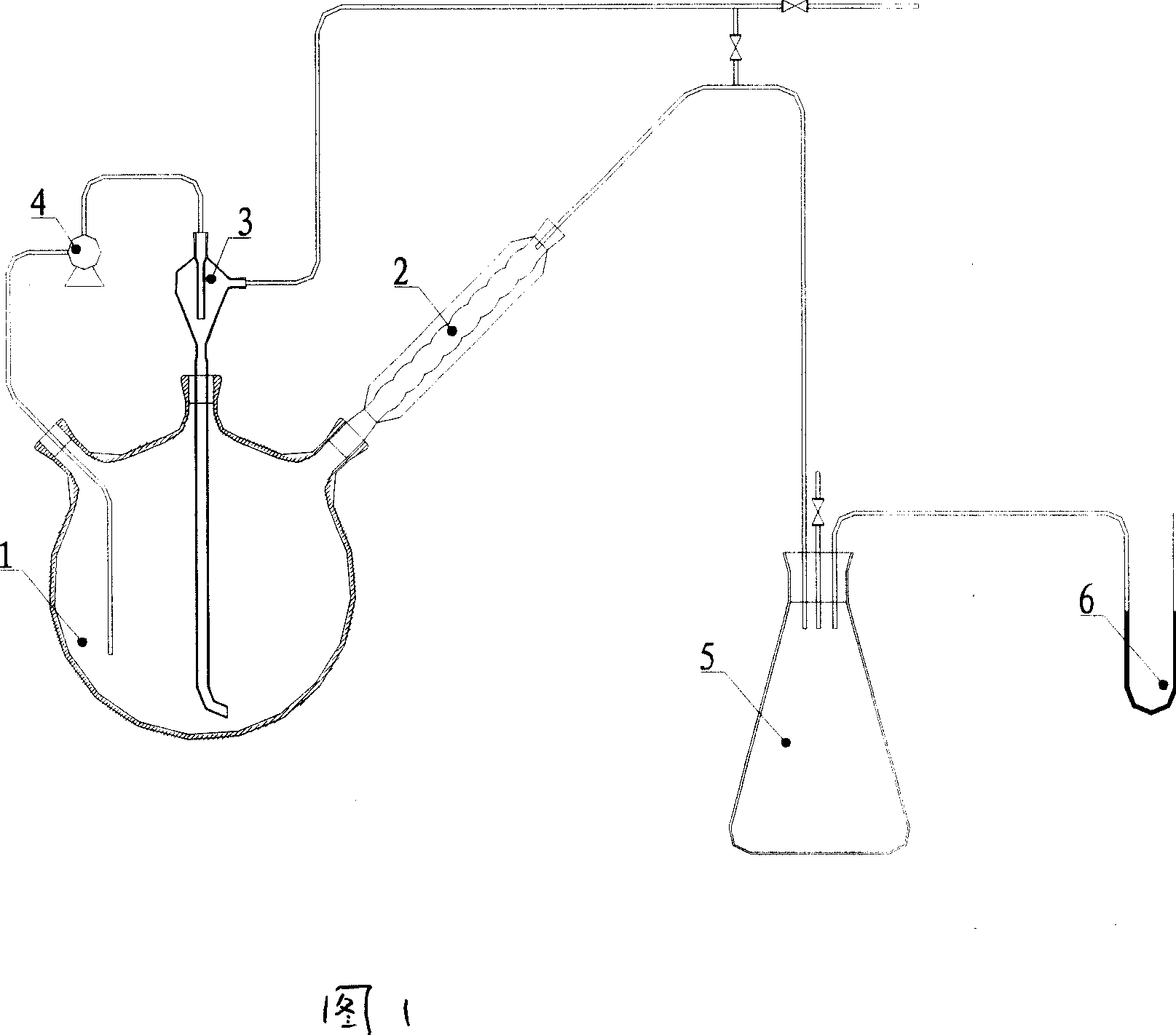

[0015] Embodiment 2: (add Venturi ejector and feed liquid circulation pump and not add the device reaction data of Venturi ejector)

[0016] The operation is carried out according to Example 1. The reaction device is added with a feed-liquid circulation pump and a Venturi injector. First, the entire system is replaced with isobutene. At the same time, the injector and the feed-liquid circulation pump are turned on, and part of the isobutene is delivered. After being measured by a U-shaped pressure gauge, Negative pressure in the kettle indicates that the isobutene gas in the kettle has reacted, and then input isobutene, and so on, until the gas chromatography monitors the BHT content to reach 90%, stop feeding isobutene, and the reaction is completed. The cumulative reaction time is 2.5 hours, the cumulative amount of isobutene used in the experiment is 58.95 g, and the theoretical value is 56 g. There is almost no waste of isobutene, and the utilization rate can be as high as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com