Manufacturing method of aluminium alloy artistic door and window

A production method and technology of aluminum alloy, applied in decorative art, fixed grille, decorative structure, etc., can solve the problems of not being able to meet the needs of material and cultural life, poor safety, easy peeling of paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

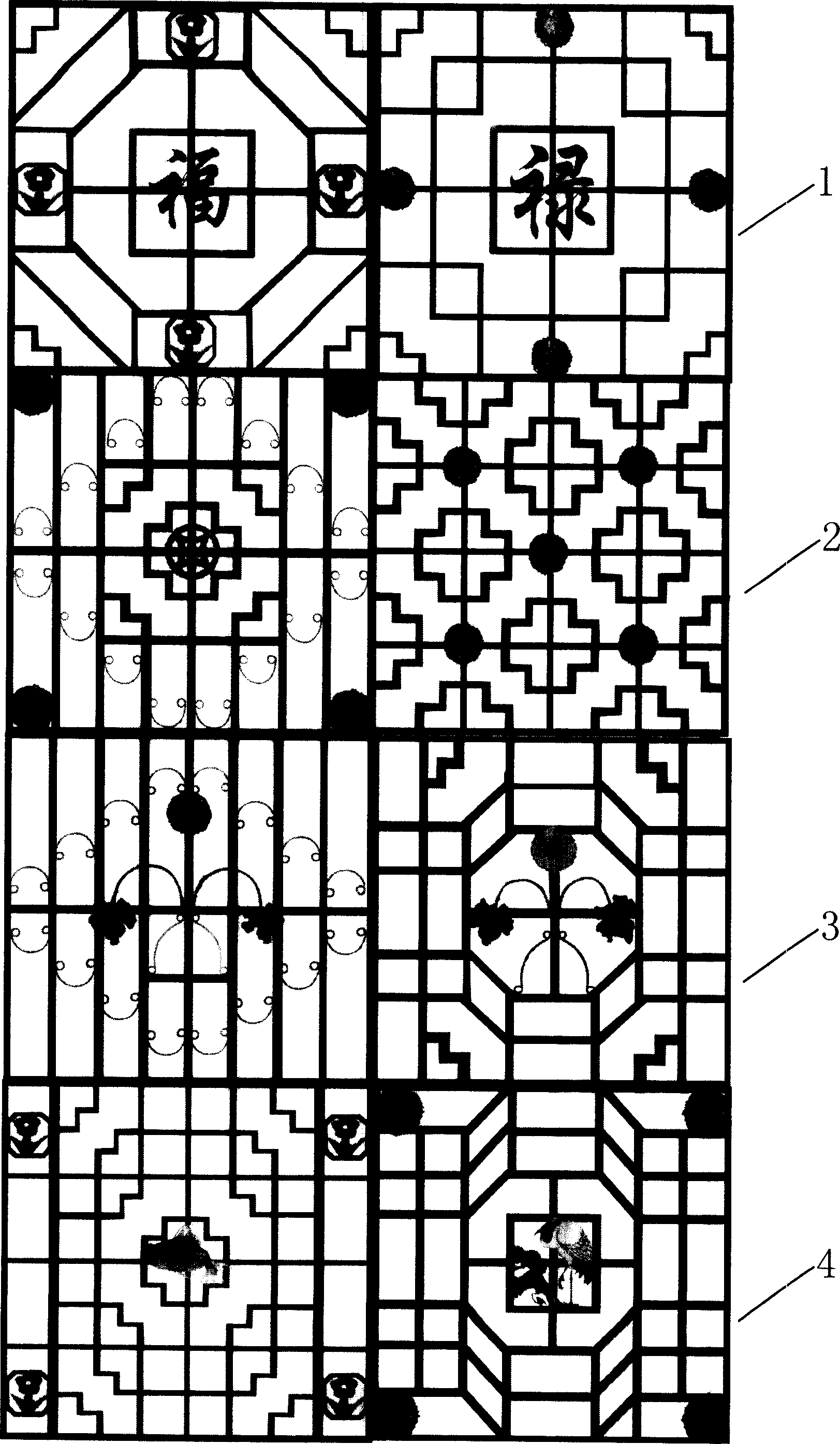

Image

Examples

Embodiment approach

[0008] The present invention adopts the following technical solutions, which mainly include the following five aspects: melting and casting aluminum alloy into bars, extruded profiles, profile aging (quenching), welding or riveting, and surface treatment.

[0009] 1. Aluminum alloy melting and casting into bars:

[0010] Aluminum-titanium alloy, aluminum-magnesium alloy, aluminum-zinc alloy, aluminum alloy and other ingredients can be used. Taking aluminum alloy as an example, the percentages of metal preparation are: aluminum 97.5, silicon 0.6, copper 0.15, manganese 0.15, magnesium 0.8, zinc 0.15, chromium 0.15, titanium 0.15, and iron 0.35. The above metals are combined and fully dissolved in the high temperature of the melting and casting furnace, and then flowed through the casting rod equipment to be cast into various types of aluminum alloy rods.

[0011] 2. Extruded profile:

[0012] The qualified aluminum alloy bars are transported into the heating furnace, heated to 490 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com