Thermotube and its sealing method

一种热管、封口的技术,应用在间接换热器、照明和加热设备等方向,能够解决热管良率及性能可靠度下降等问题,达到提升机械强度、延长使用寿命、降低泄漏率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

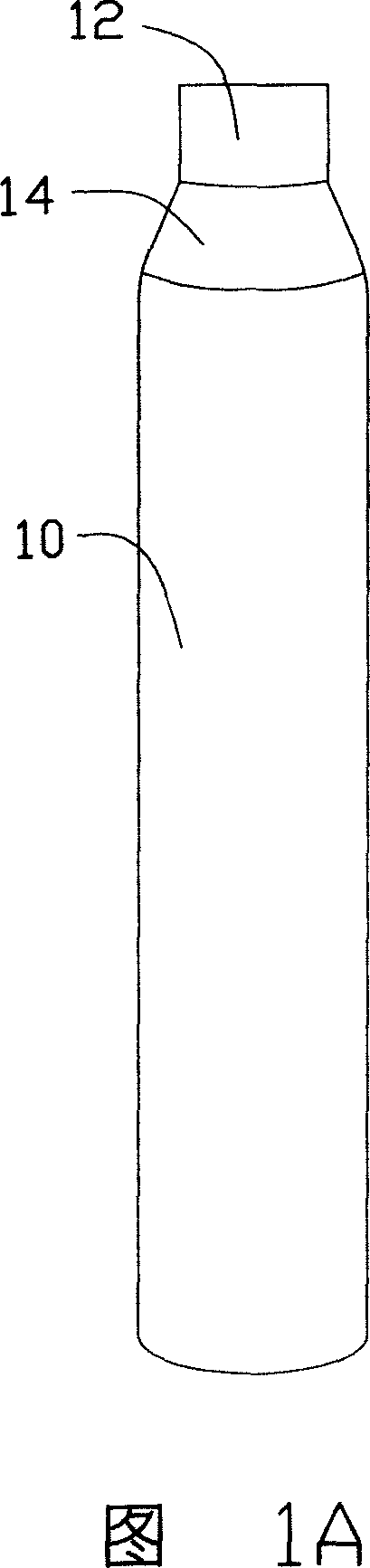

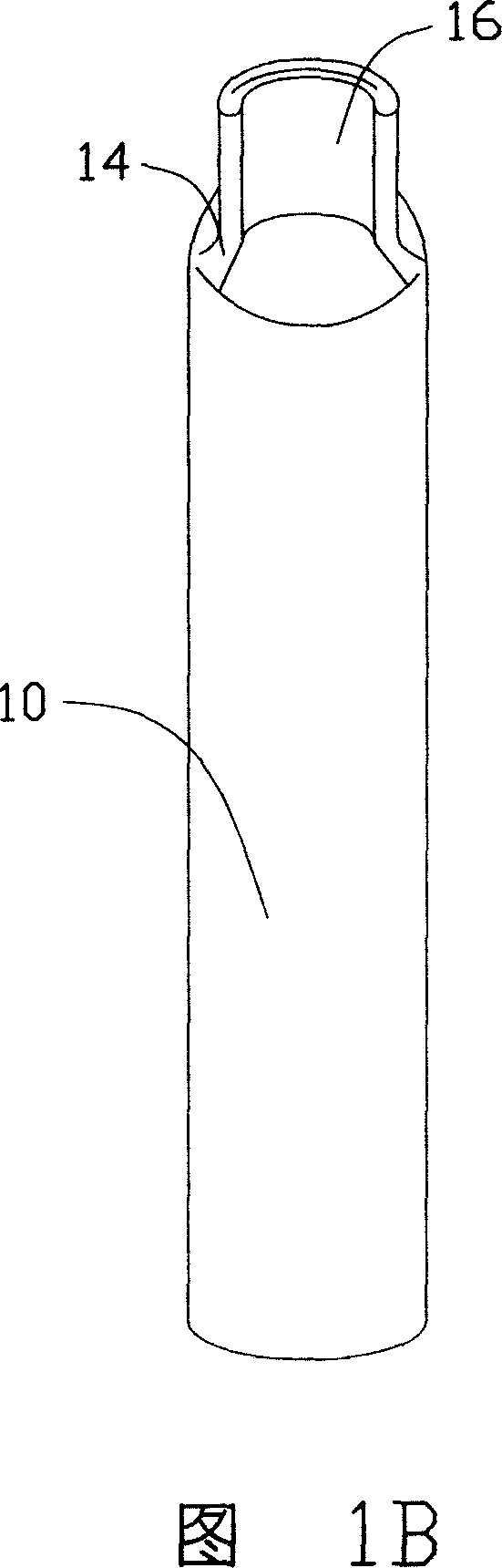

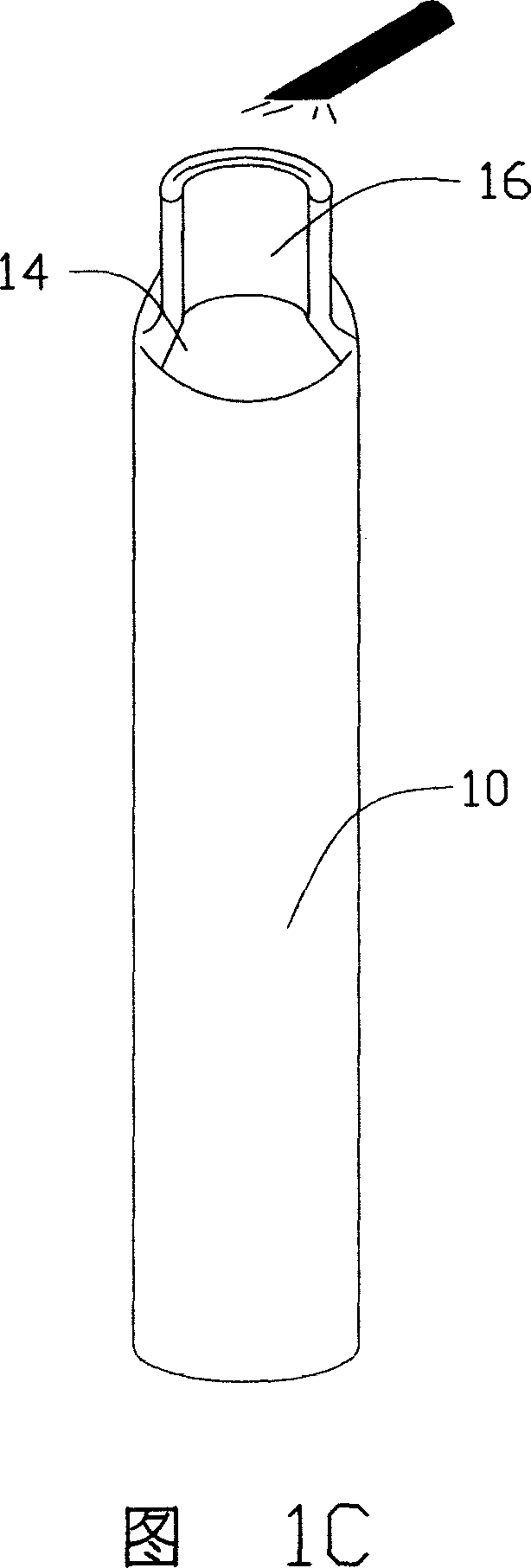

[0015] Please refer to FIGS. 1A to 1D, which are schematic diagrams of the sealing process of the heat pipe of the present invention. The heat pipe sealing process is as follows: a tube body 10 is provided. The tube body 10 includes an open end 12 and a shrinking tube section 14 adjacent to the open end 12 (as shown in Figure 1A). The tube is provided with a capillary structure and filled with an appropriate amount of working fluid. Use a set of flattening dies to stamp the open end 12 to be flattened to form an arc-shaped sealing section 16, as shown in Figure 1B; subsequently, the use of tungsten argon arc welding (TIG) directly The sealing section 16 of the heat pipe is fusion welded at high temperature (as shown in FIG. 1C), so that the shell at the end of the sealing section 16 forms an integral welding section 18. FIG. 1D shows the heat pipe sealing structure manufactured according to the above method, which includes a shrinking tube section 14, a sealing section 16 and a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com