Method for regulating photoelectric probe position of high dense CD reading head

A technology of photoelectric detectors and adjustment methods, which is applied to optical detectors, optical recording/reproduction, optical head manufacturing, etc., can solve the problems of troublesome adjustment process and complicated servo circuits, and achieve easy adjustment and positioning accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

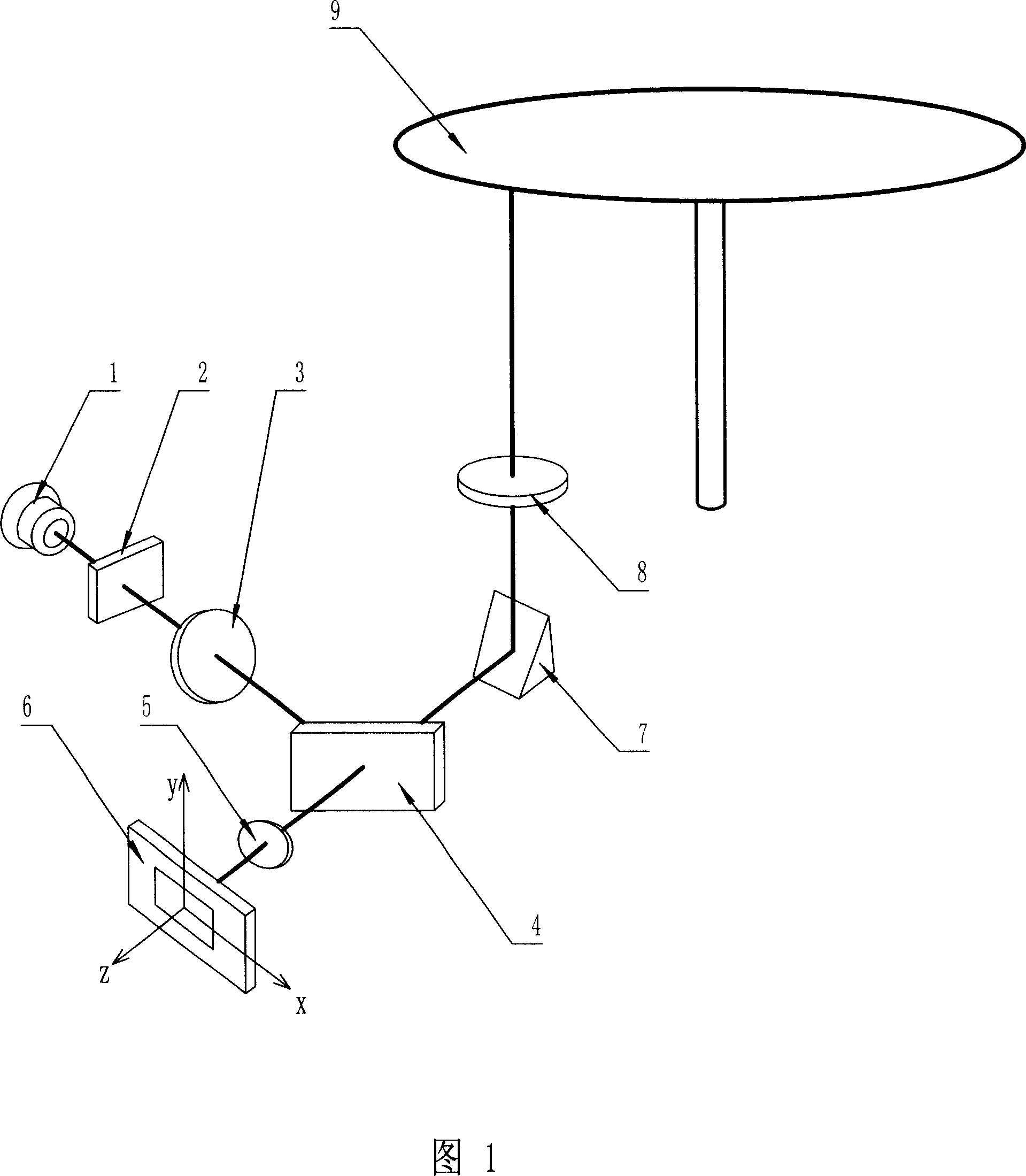

[0022] As shown in Figure 1, an optical path structure of a high-disc optical disc read head includes: a semiconductor laser 1, a grating 2, a collimating mirror 3, a half-transparent mirror 4, a cylindrical mirror 5, a photodetector 6, a reflector Mirror 7, objective lens 8, optical disc 9 and main shaft 10, main shaft 10 is driven by main shaft motor; For the optical path structure of this optical disc reading head, the method for adjusting the photodetector position of high-density optical disc reading head of the present invention, its steps are :

[0023] 1. In the optical path structure of the optical disc reading head, a plane mirror is used to replace the optical disc 9 to ensure that the optical axis of the plane mirror reflection surface and the objective lens 8 are aligned;

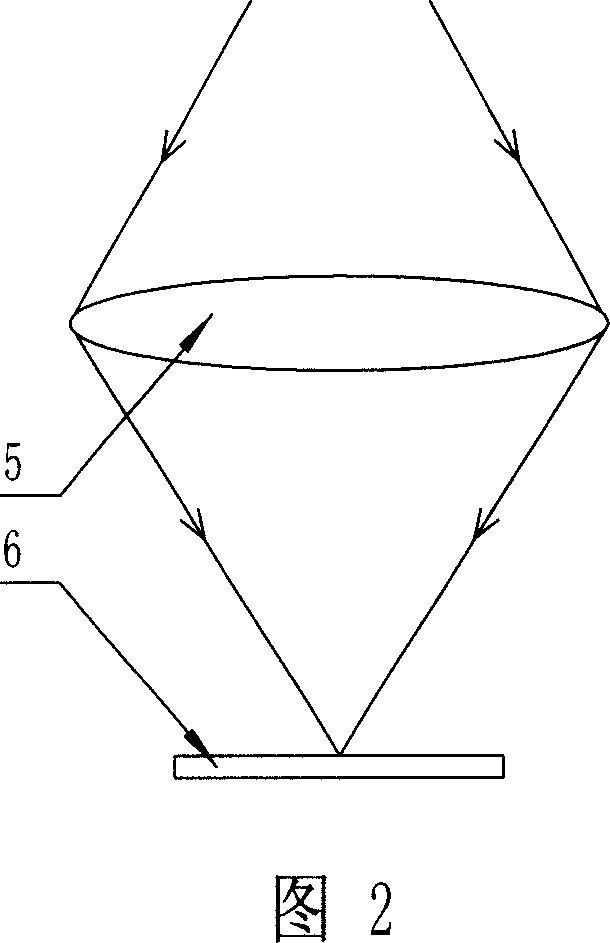

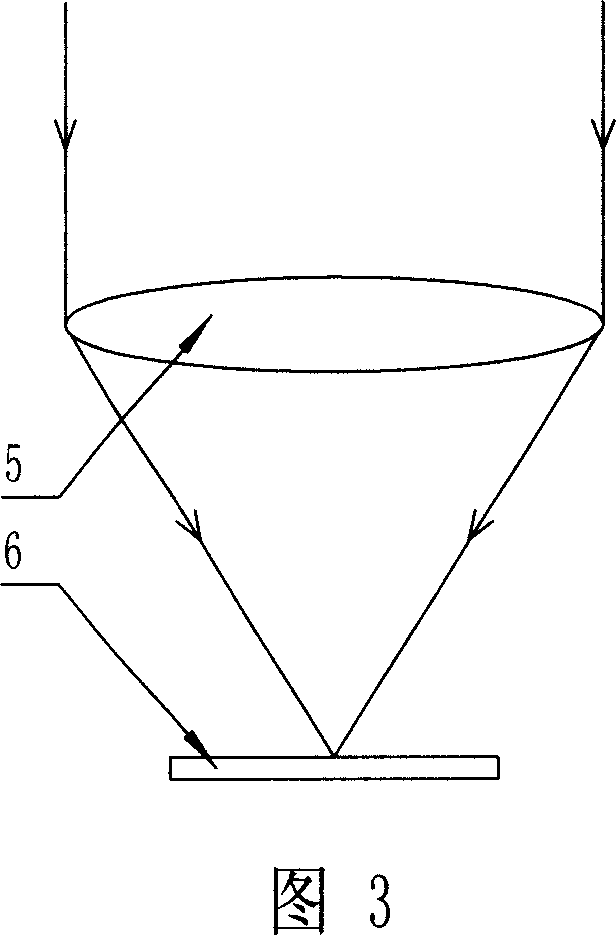

[0024] 2. Remove the cylindrical mirror 5 of the optical disc reading head, adjust the distance between the plane mirror and the objective lens 8 to be the focal length of the objective lens 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com