Voice coil motor and method for controlling displacement by magnetic spring force

A voice coil motor, magnetic spring technology, applied in position/direction control, non-electric variable control, control/adjustment system and other directions, can solve the problems of damping glue, torsional deformation of shrapnel sub-support arm 3004, disadvantage, etc., to achieve enhanced The effect of drop reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

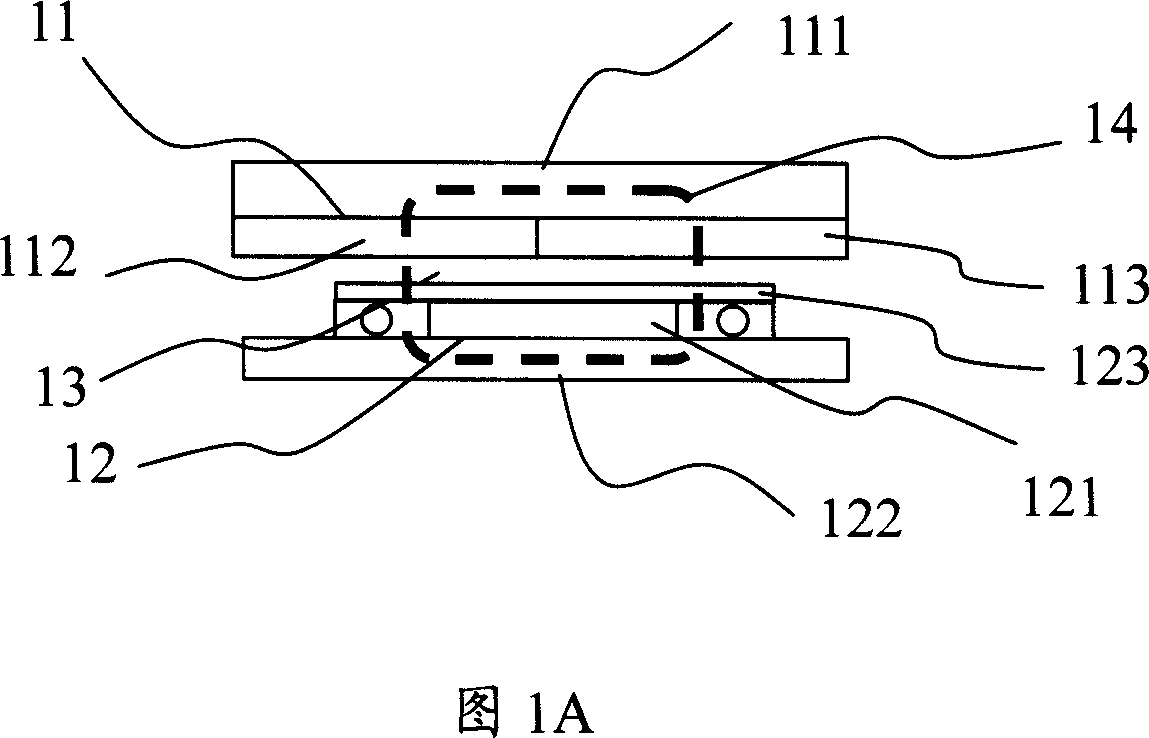

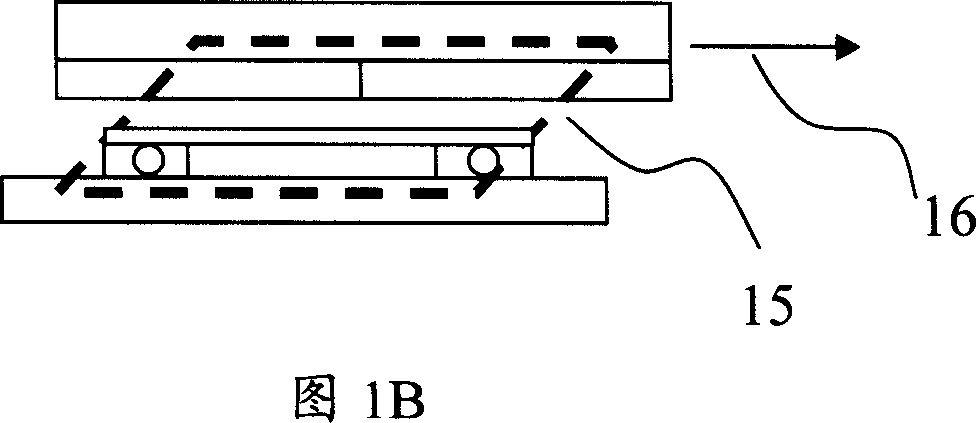

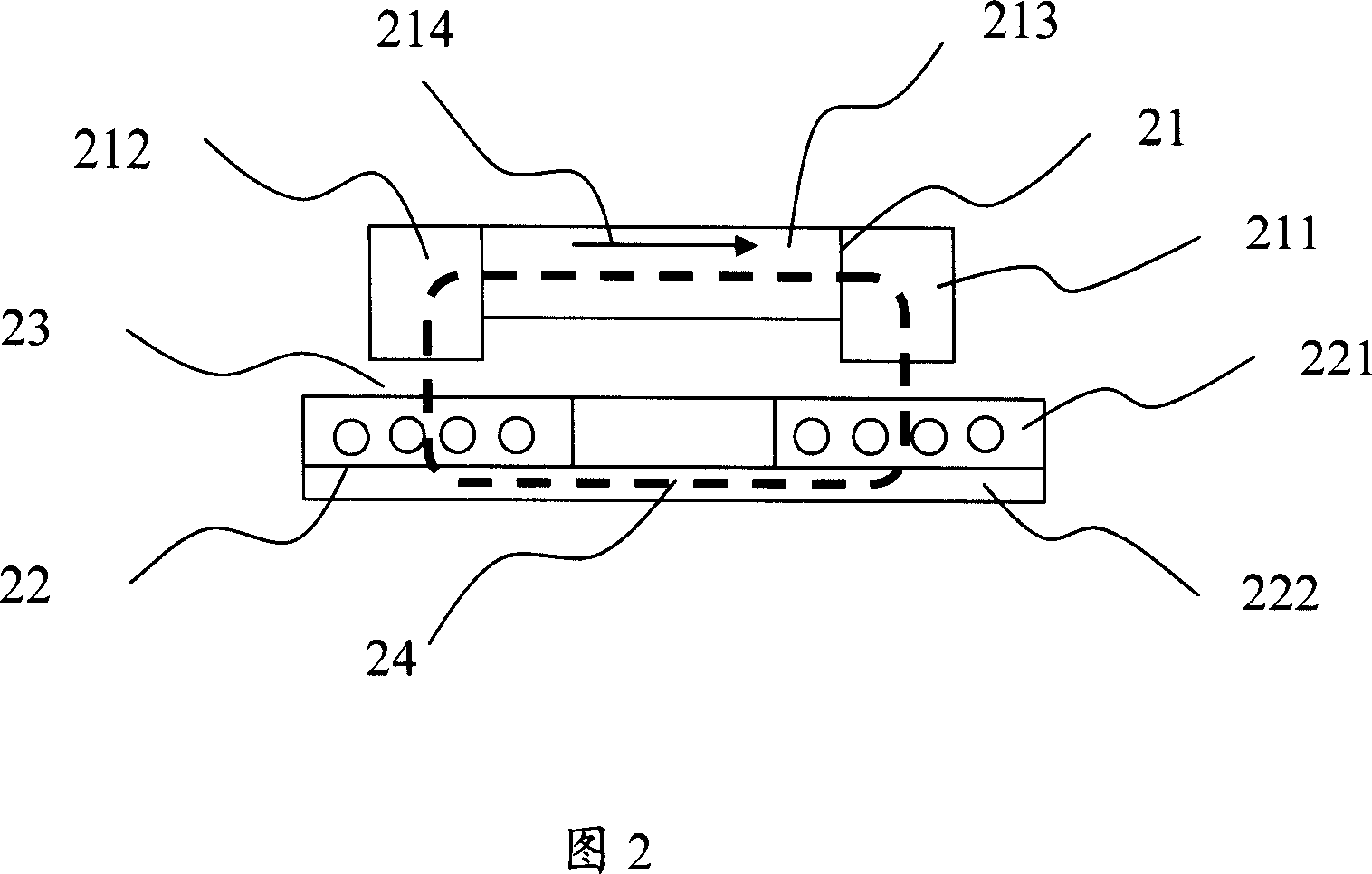

[0354] Existing voice coil motor, as can be seen from the foregoing description, its moving part is made of a simple coil, so there is no other coupling force between the moving part and the fixed part except the propulsive force along the displacement direction; the voice coil motor of the present invention Circle motor, its basic principle is the embodiment shown in Figure 1A, a magnetic circuit part 11 has a yoke 111, and the first magnet 112 and the second magnet 113 of opposite polarity are pasted on its inner surface, certainly, this two magnets can be made of A surface has magnets with different polarities. A circuit component 12 has a magnetic conductor 122 in addition to a coil 121. The two are rigidly connected as one. There is an air gap 13 between the magnetic circuit component 11 and the circuit component 12. A magnetic field 14 starts from the first magnet 112, passes through the coil 121 through the air gap 13, reaches the magnetic conductor 122, passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com