Method for preparing nano silver by using wool keratin

A wool keratin, nano-silver technology, applied in the directions of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of easy control of conditions, good dispersion and stability, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Extraction of wool keratin: heat 75g of urea at 160°C, add 10g of shredded wool after the urea melts, treat at a constant temperature of 160°C for 30min, then add water under continuous stirring, cool to 50°C, filter, and The obtained filtrate was put into a dialysis bag with a theoretical molecular weight cut-off of 3000 Da, and flow-dialyzed with distilled water for 72 hours. After the dialysate was filtered, it was diluted with water to 2 L to obtain a wool keratin solution.

[0032] (2) Preparation of nano-silver: take a certain amount of wool keratin solution obtained in step (1), dilute with water until the keratin concentration is 0.0057g / L, 0.0170g / L and 0.0227g / L weighing method), adjust the pH value to 11 with sodium hydroxide, and then slowly add silver nitrate solution to it at a uniform speed to a concentration of 0.170g / L. Aqueous solution of silver nanoparticles.

[0033] The molecular mass of keratin in the wool keratin solution obtained in this emb...

Embodiment 2

[0039](1) Extraction of wool keratin: heat 100g of urea at 160°C, add 10g of shredded wool after the urea melts, treat at a constant temperature of 160°C for 30min, then add water under constant stirring, cool to 50°C, filter, and The obtained filtrate was put into a dialysis bag with a theoretical molecular mass cut-off of 3000 Da, and flow-dialyzed with distilled water for 72 hours. After the dialysate was filtered, it was diluted with water to 1 L to obtain a wool keratin solution.

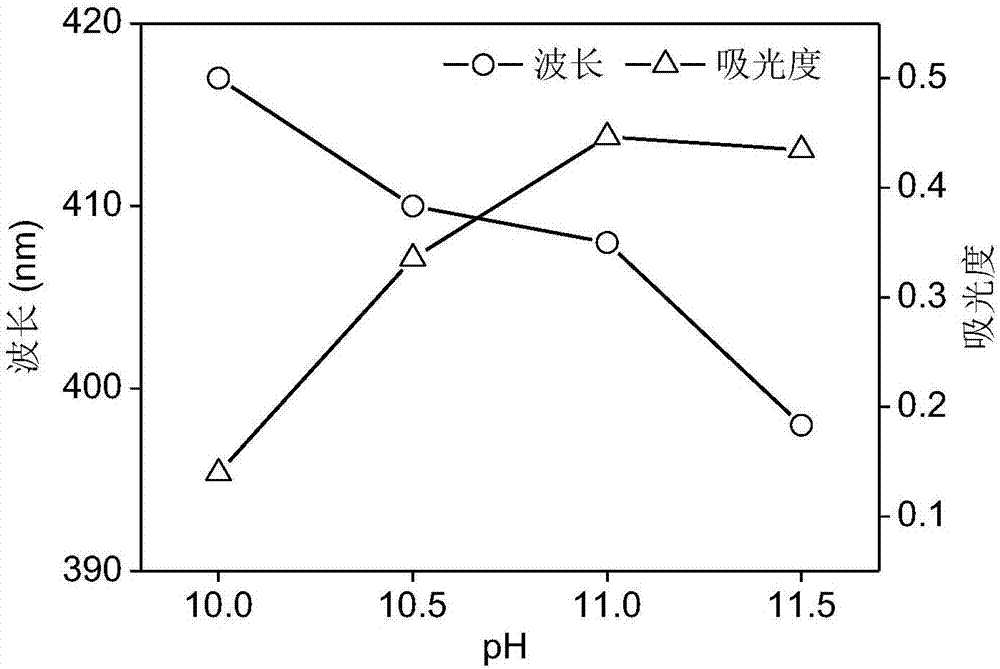

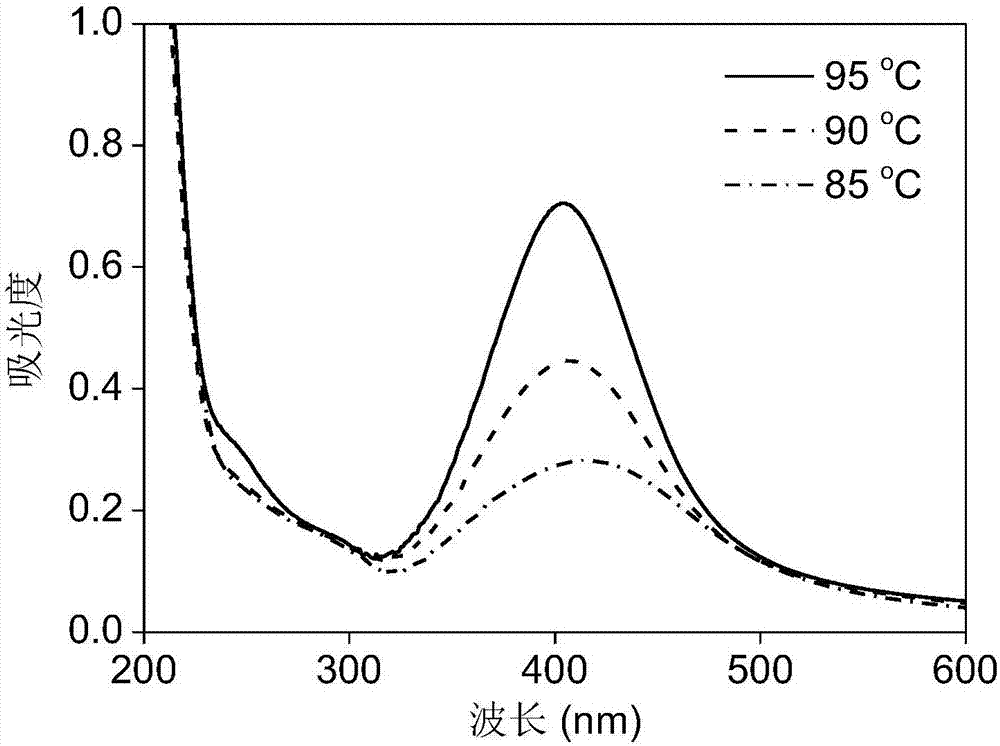

[0040] (2) Preparation of nano-silver: Take a certain amount of wool keratin solution obtained in step (1), dilute with water until the keratin concentration is 0.0170g / L, adjust the pH value to 10, 10.5, 11.0 and 11.5 with sodium hydroxide , and then slowly dropwise add silver nitrate solution to it at a uniform speed until its concentration is 0.170g / L. After the dropwise addition, raise the temperature to 90° C., and keep it warm for 40 minutes to obtain an aqueous solution of nano silver.

...

Embodiment 3

[0043] (1) Extraction of wool keratin: heat 50g of urea at 160°C, add 10g of shredded wool after the urea melts, treat at a constant temperature of 160°C for 30min, then add water under continuous stirring, cool to 50°C, filter, and The obtained filtrate was put into a dialysis bag with a theoretical molecular weight cut-off of 3000 Da, and flow-dialyzed with distilled water for 72 hours. After the dialysate was filtered, it was diluted with water to 2 L to obtain a wool keratin solution.

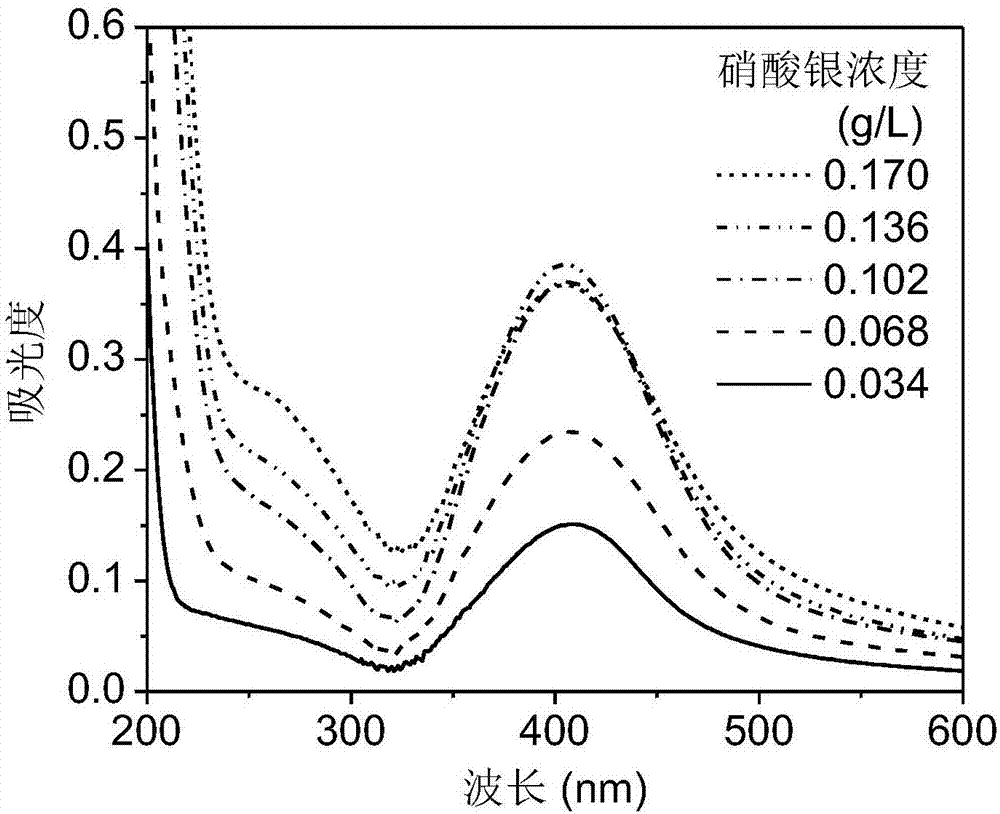

[0044] (2) Preparation of nano-silver: Take a certain amount of wool keratin solution obtained in step (1), dilute it with water until the keratin concentration is 0.0170g / L, adjust the pH value to 11 with sodium hydroxide, and then drop it slowly at a uniform speed Add silver nitrate solution until the concentration is 0.034, 0.068, 0.102, 0.136 and 0.170g / L. After the dropwise addition, raise the temperature to 90°C and keep it warm for 40 minutes to obtain the nano silver aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com