A method of reinforcing a structure and a clamp

A technology of clamping device and magnetic clamping device, which is applied in the direction of workpiece clamping device, lamination device, transportation and packaging, etc., can solve the problems of damage to the surrounding structure, time-consuming installation and removal, etc., and achieve rapid implementation and rapid The effect of dismantling and reducing the effective cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

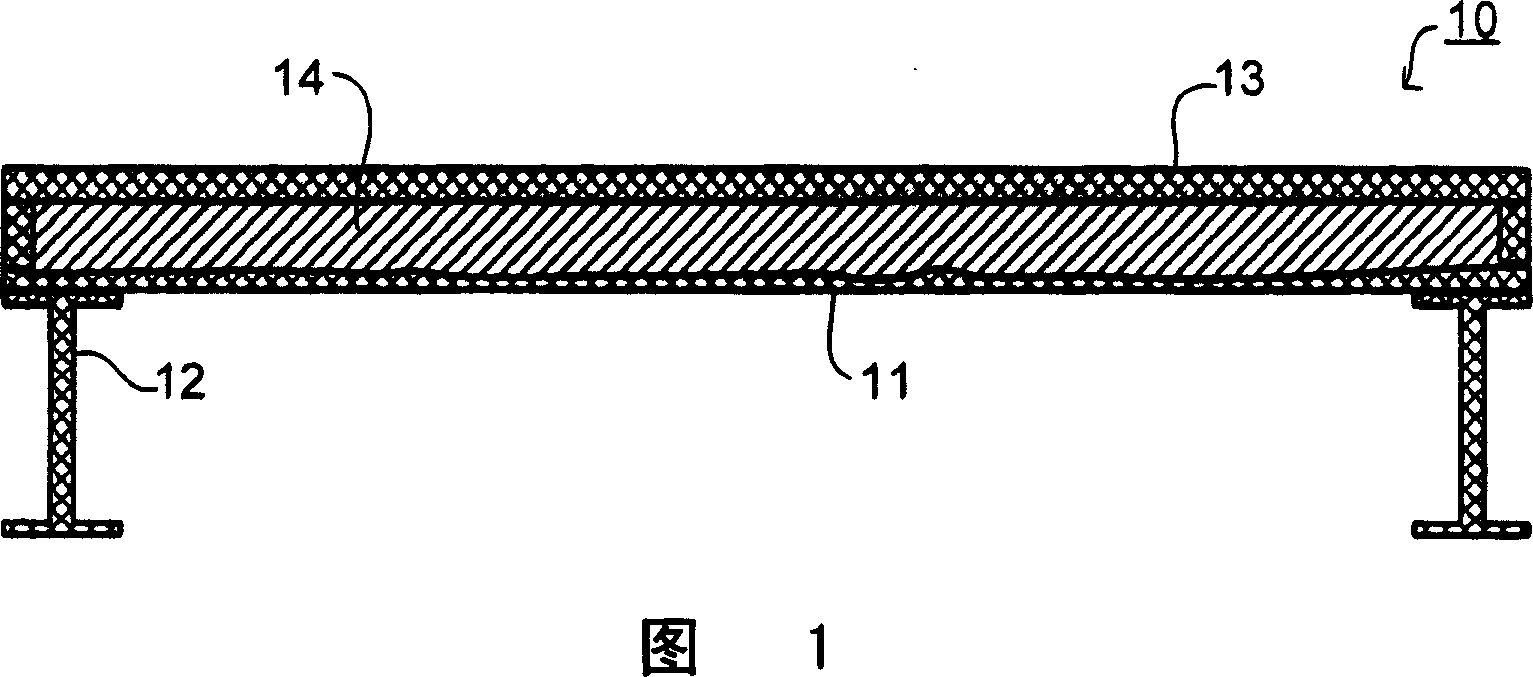

[0023] Figure 1 is a sectional view of the deck of a ro-ro ship which has been strengthened by the method of the present invention. A metal plate 11 forming the original deck is supported by beams 12 and bulb flats (not shown). Various pipes and cables (not shown) and fireproofing materials are attached to the underside of the metal plate 11 .

[0024] The metal plate 11 has an original thickness. For example the thickness of the deck of a ro-ro ship would typically be in the range of 10 mm to 20 mm. Typical corrosion and wear reduce the thickness of the metal plate 11 by approximately 0.15 mm per year. Under these environmental conditions, the sheet metal 11 needs to be replaced or strengthened after about twenty years of use.

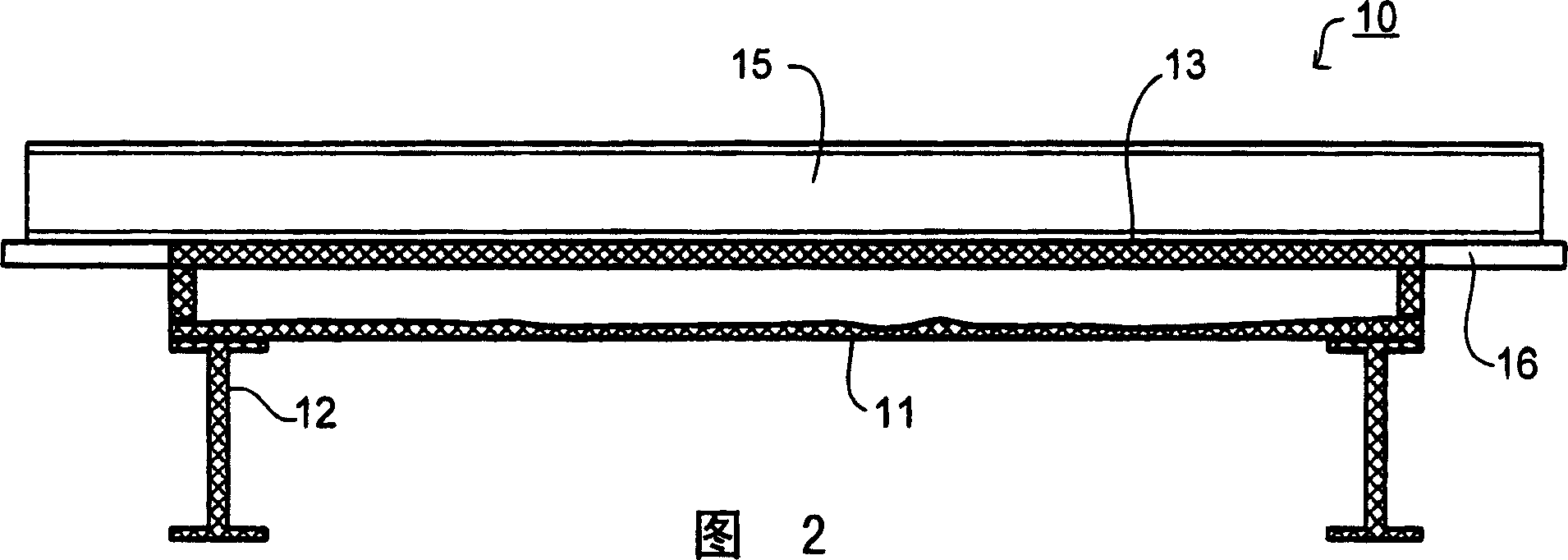

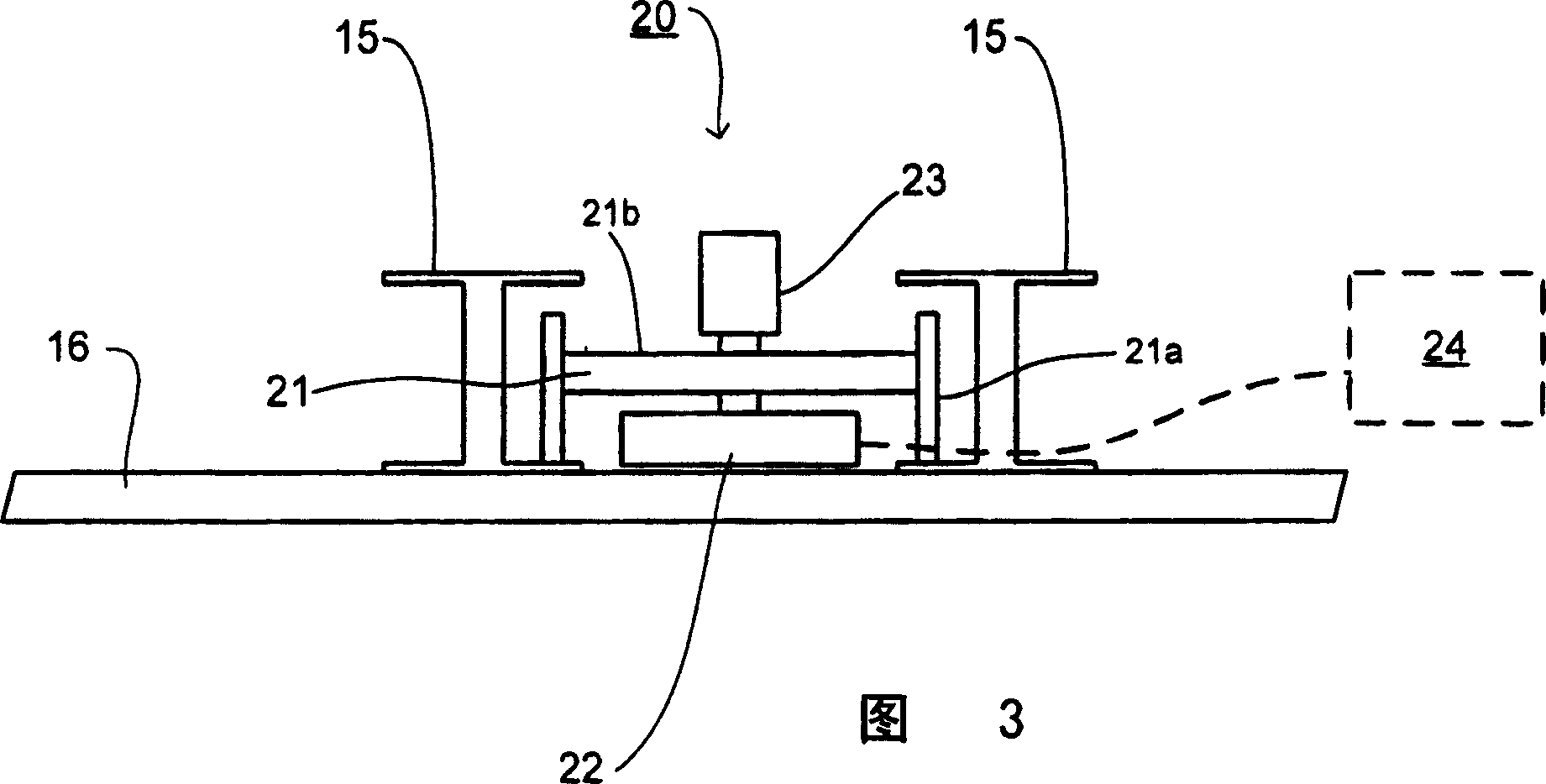

[0025] The method of strengthening of the present invention consists in attaching a reinforcing metal layer 13 to the metal plate 11 of the existing structure. The metal layer 13 is arranged in spaced relation to the metal plate 11 whereby a cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com