Flexible drive shaft casing for power operated rotary knife

A technology of drive shaft and flexible shaft, which is applied in metal processing, bone cleaning device, boning scissors/bone crusher, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

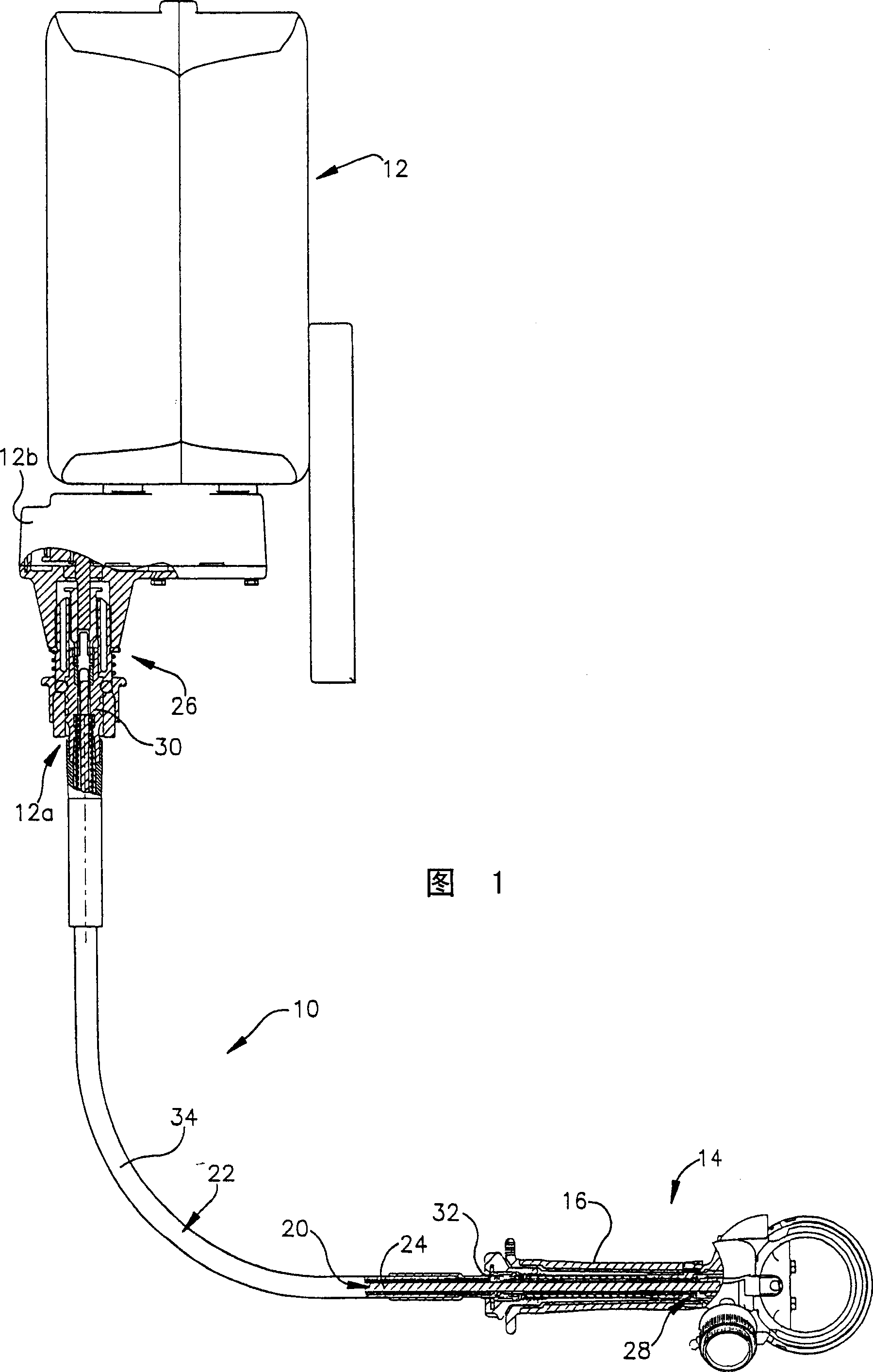

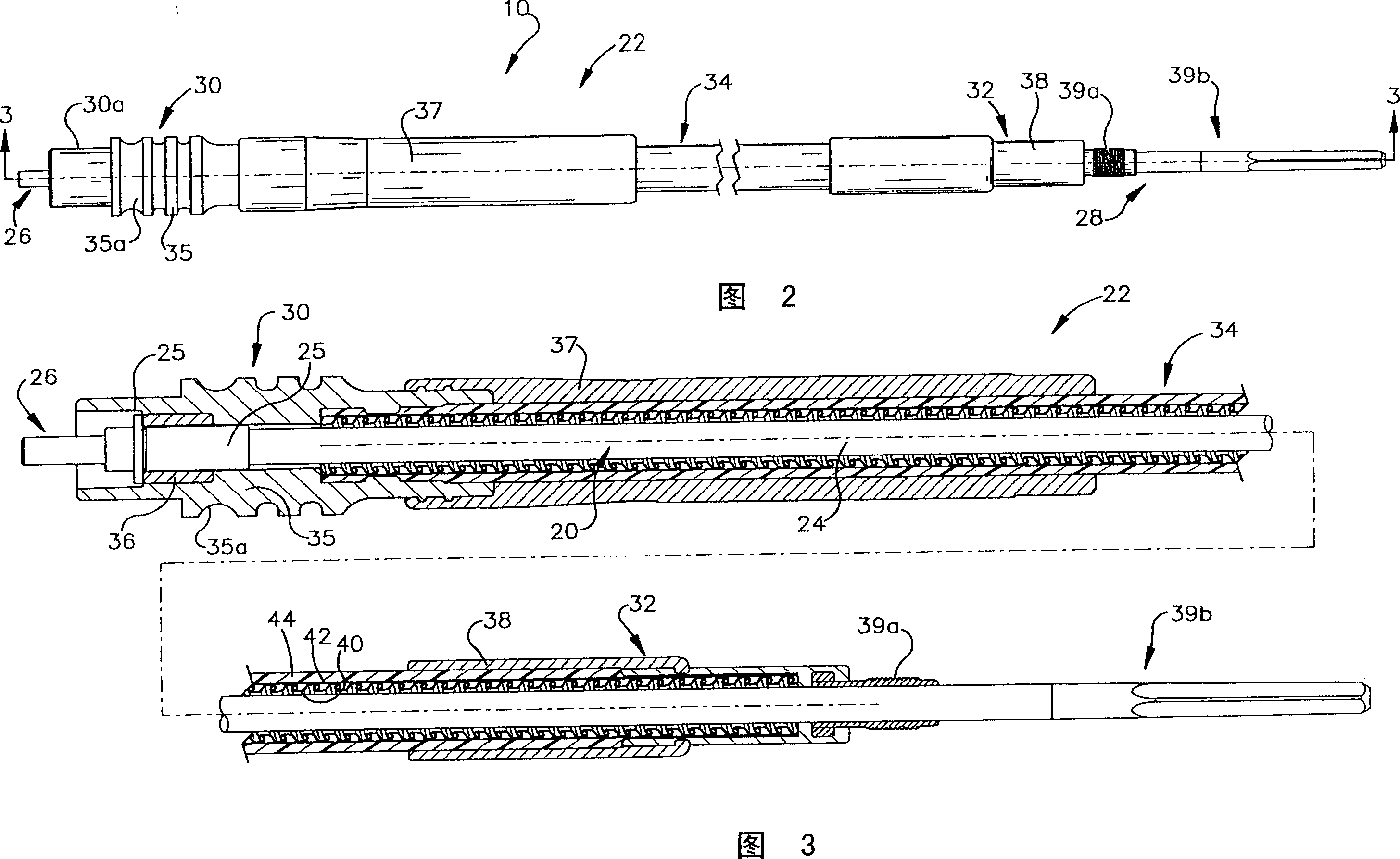

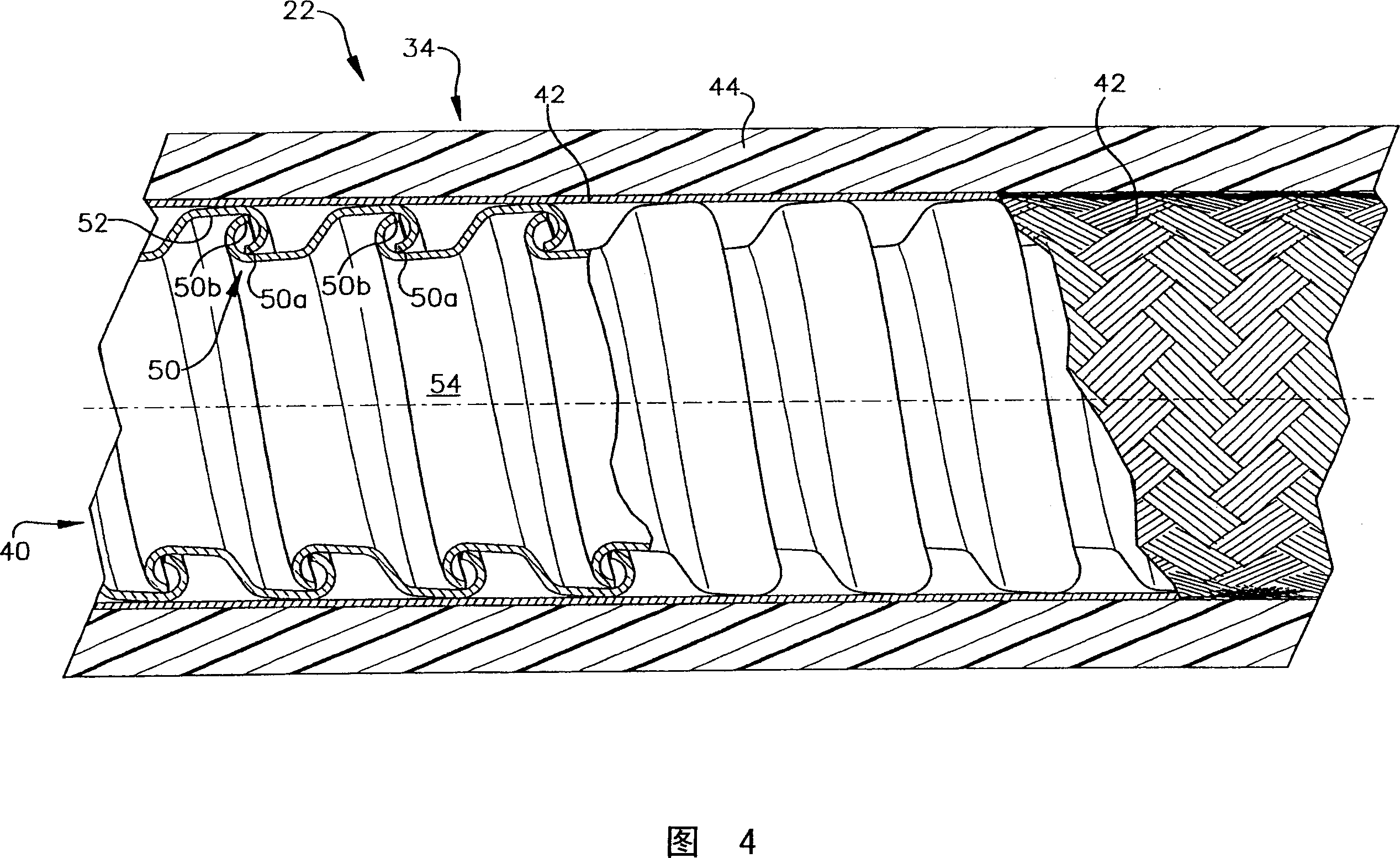

[0015] A flexible drive shaft transmission is indicated generally at 10 in FIG. 1 . The flexible drive transmission 10 is used to transmit drive from a motor 12 to a power tool 14, such as a rotary knife. 1, the described flexible shaft drive transmission 10 includes a flexible drive shaft assembly 20 connectable between the drive motor 12 and the tool 14, a tubular sleeve surrounding and coaxial with the drive shaft assembly 20 22, and a relatively viscous lubricant that is not shown in the sleeve 22. Where the drive 10 is used to operate a knife or other food industry tool, the lubricant is edible.

[0016] In the description of FIG. 1 , the motor 12 is an electric motor suspended above the workstation. The tool 14 is a rotary knife of the type used in the food processing industry to finish cuts of meat. The knives are held and pulled by hand through the meat at the workstation to trim the fat, remove the meat from the bone, slice the meat, and the like. The knife 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com