Polyporus rhinoceros cooke extract having anticancer and immunity enhancing activity and preparation method thereof

A technology of Ganoderma lucidum extract and tiger milk Ganoderma lucidum, applied in the field of bioengineering technology and natural polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The water extract of embodiment 1 tiger milk Ganoderma lucidum

[0083] The sclerotia of tiger milk Ganoderma lucidum artificially cultured (provided by Sanming Fungi Research Institute, Fujian Province) was peeled and crushed, and then passed through a 0.5mm sieve to obtain sclerotia powder. About 20 grams of sclerotia powder was extracted with 95-100° C. hot water (the weight-to-volume ratio of powder to hot water was 1:25) for 2 hours. After cooling to room temperature, the mixture was centrifuged at 10,000×g for 30 minutes to separate the supernatant. After the collected supernatant was ultrafiltered (the pore size is 10000MWCO), it was concentrated until the total solute (TDS) value was below 10. The crude product thus obtained was lyophilized to give a white product labeled HWE1.

[0084] The yield (percentage by weight) of the water extraction method is 8.62% of the dry weight of sclerotia.

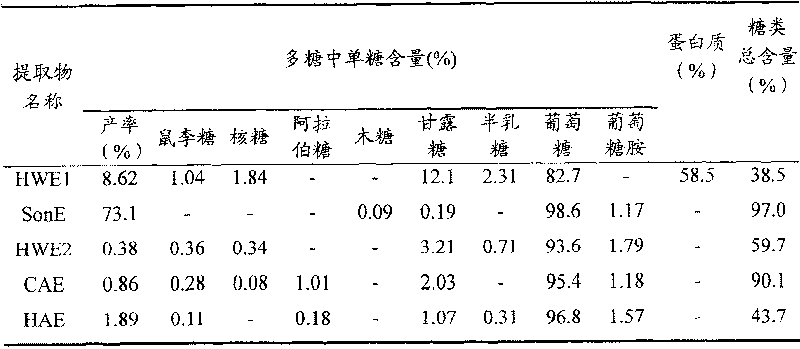

[0085] The components in HWE1 were analyzed by mass spectrometry.

...

Embodiment 2

[0088] Using the same method as in Example 1, another batch of artificially cultivated tiger milk Ganoderma lucidum sclerotia was extracted, and the protein and polysaccharide content of the obtained extract was similar to that of Example 1, but the glucose content in the polysaccharide was as high as 98.5%. And only trace amounts of mannose, galactose, ribose and / or rhamnose.

Embodiment 3

[0089] Example 3 Tiger milk ganoderma-ultrasonic extract

[0090] Sclerotia powder was prepared in the same manner as in Example 1. About 20 grams of sclerotia powder was soaked in 1 M sodium hydroxide aqueous solution at a ratio of 1:25 (weight to volume ratio, w:v) to make it swell for 48 hours. The mixture was then transferred to a large beaker and neutralized with 4M hydrochloric acid until pH 7.0. Put an ultrasonic head (Sonics, VCX600, 600W) and a mechanical stirring rod (Stuart Scientific Stirrer, SS10, 80W, 50Hz) into the large beaker containing the mixture, stir the mixture continuously under the condition of ice bath, and extract it ultrasonically for 30 minutes . The mixture was then centrifuged at 10,000 rpm for 30 minutes to separate the supernatant, and the remaining residue was designated as 1. The collected supernatant was dialyzed against distilled water (pore size 6000-8000 MWCO) and then lyophilized. This gave the product as a white powder, labeled SonE....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com