Vertical kiln raw material comminutor

A granulator and raw meal technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of different particle sizes, large amount of water added to raw meal, increased heat consumption of shaft kiln, etc., to achieve ventilation resistance reduction, burning Low heat consumption and uniform air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

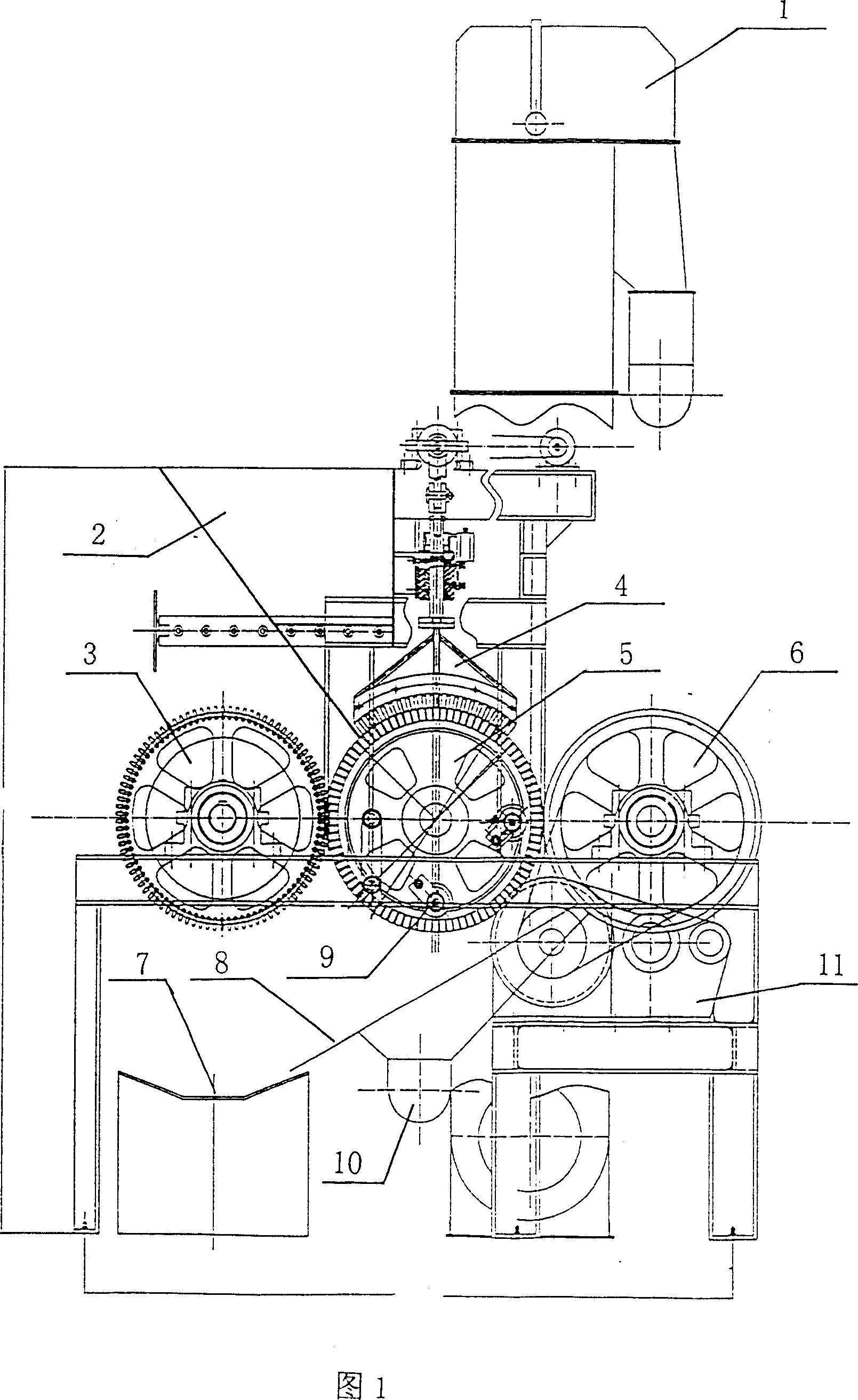

[0007] Referring to the accompanying drawings, its structure is that a filler device 4 is provided below the hopper 2, and the filler device 4 is connected to the female mold 5, and the female mold 5 is respectively connected to the mold ejection device 3, the mold repair ring 6, and the stripping module 9. The module 9 is arranged on the top of the vibrating screen 8, the bottom pin of the ball mold is housed on the female mold 5, and the reducer 11 is respectively connected with the female mold 5, the mold ejection device 3, and the mold repair ring 6 through bearings.

[0008] work process

[0009] The hoist 1 installed on the side of the main machine sends the material into the hopper 2 under the control of the first motor, and the material enters the filling device 4 working under the control of the second motor through the hopper 2. Before that, the mold ejection device 3. The bottom pins of the ball mold on the mother mold 5 discharge the empty mold of the material ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com