Vibration detection and control method of plate blank continuous casting crystallizer vibration platform

A crystallizer vibration and vibration detection technology, applied in the configuration of manufacturing tools, casting equipment, indicating equipment/measuring equipment, etc., can solve the problems of unable to meet vibration parameters, unable to respond and generate corresponding control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

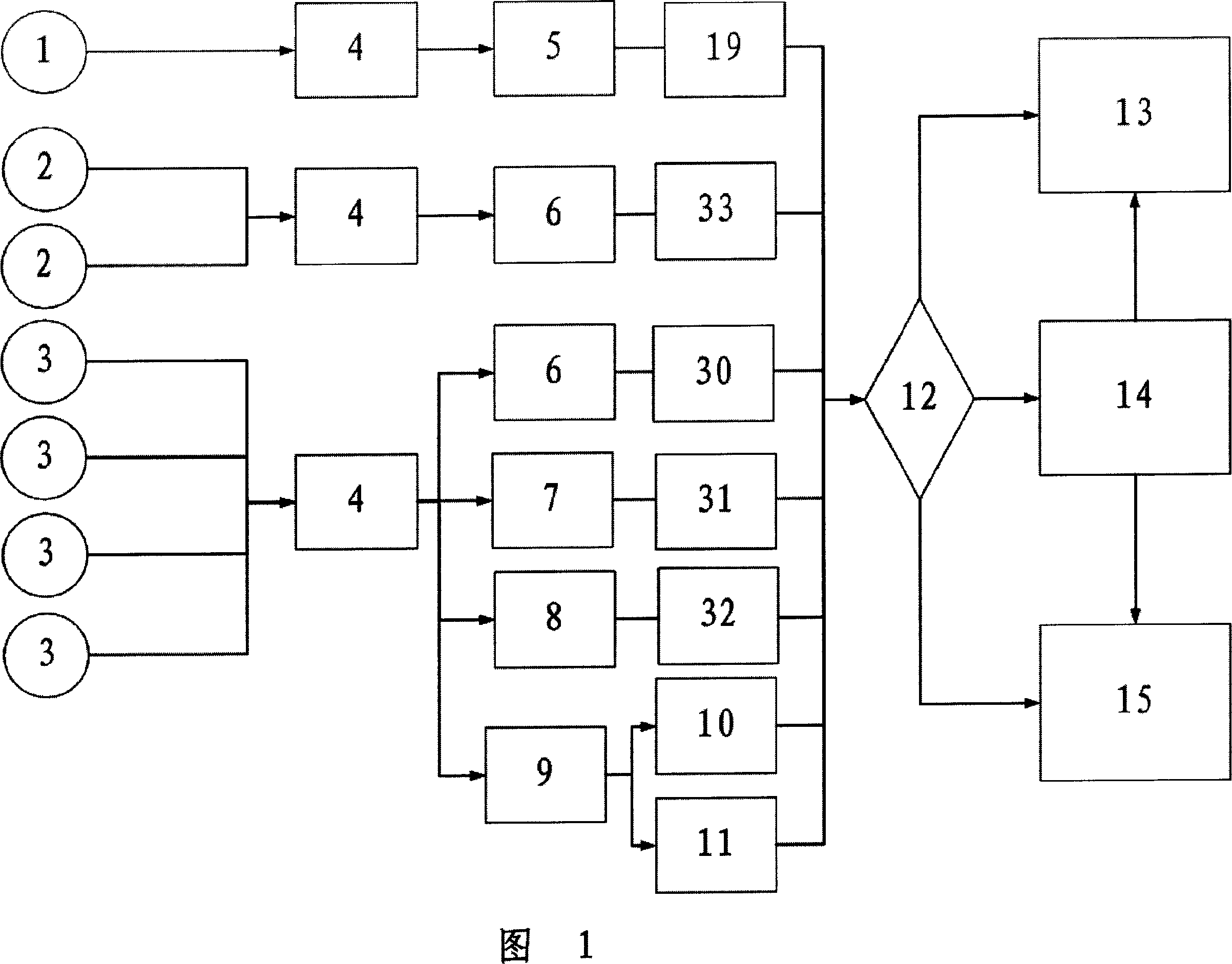

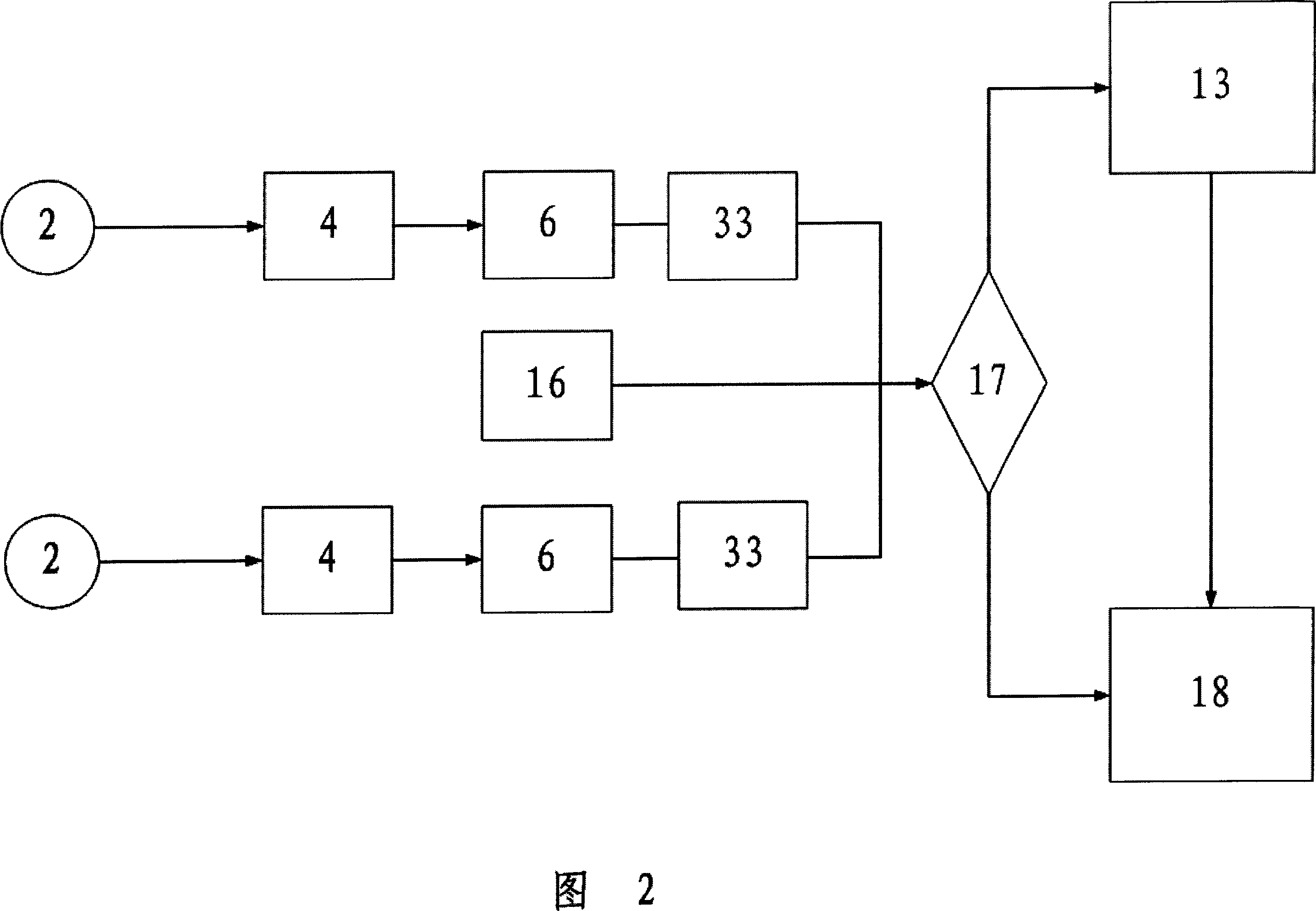

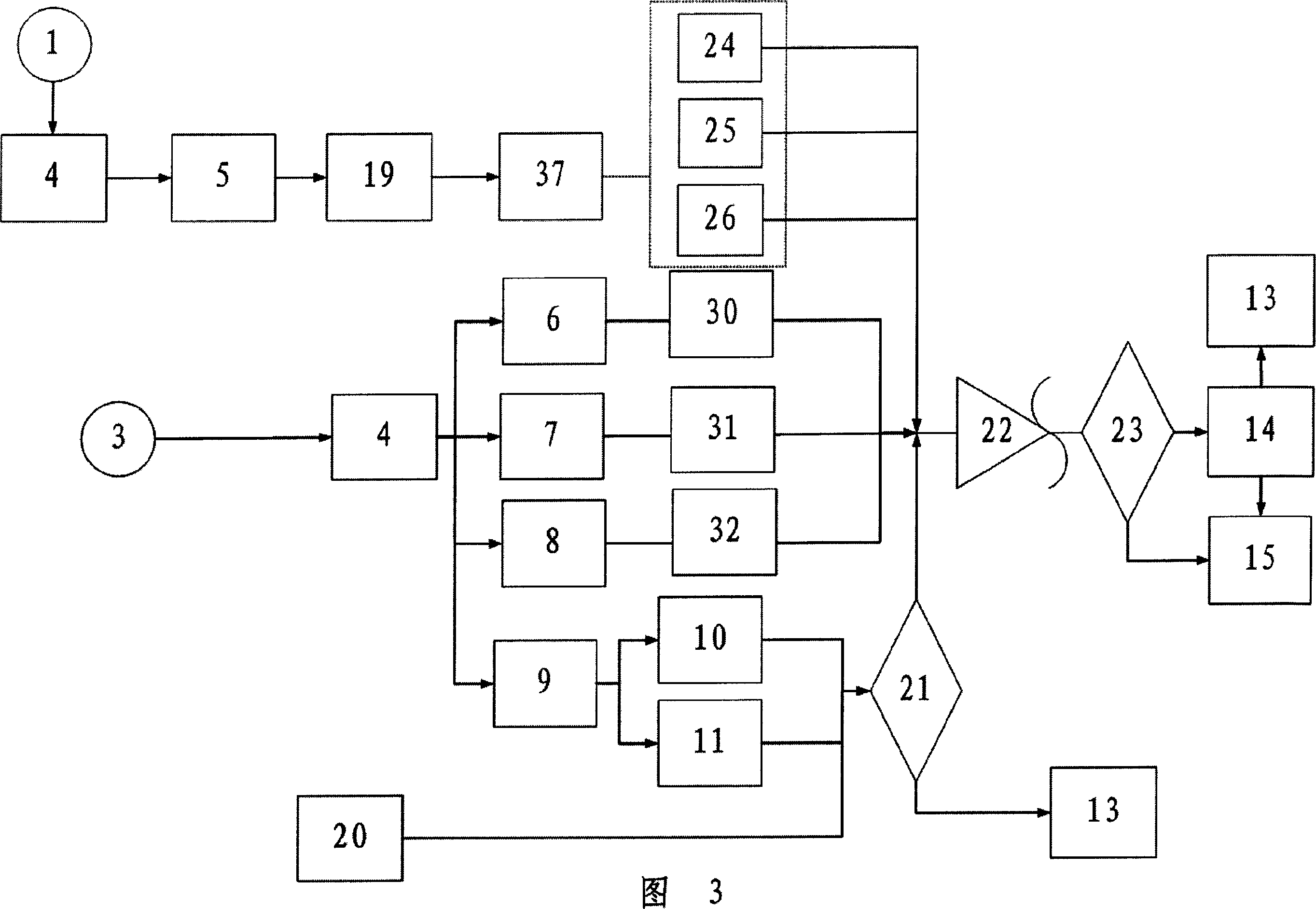

Method used

Image

Examples

Embodiment Construction

[0028] The form of crystallizer vibration equation that the present invention adopts is the non-sinusoidal vibration waveform equation based on composite function, and this equation is the fundamental principle that method realizes control and detection to rely on, and the mathematical expression of this equation is:

[0029] y=-r(_) where

[0030] In the formula, y is the displacement in the vibration direction, the unit is mm; r is the vibration amplitude, the unit is mm; f is the vibration frequency, the unit is l / min; t is the time experience, the unit is s; e is the waveform coefficient, and the coefficient is used To adjust the skew rate of the vibration waveform, when e=0, what the waveform equation expresses is a sine wave on the time axis. This formula can conveniently express the vibration waveform equation under any slope condition, so it is the most ideal choice for the control method.

[0031] The skew rate of the waveform is a key parameter in the crystallizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com