Hand-held cut-off machine

A grinding wheel cutting machine, portable technology, applied in metal sawing equipment, stone processing equipment, grinding machines, etc., can solve problems such as cutting effects, and achieve the effect of reducing the risk of contact and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

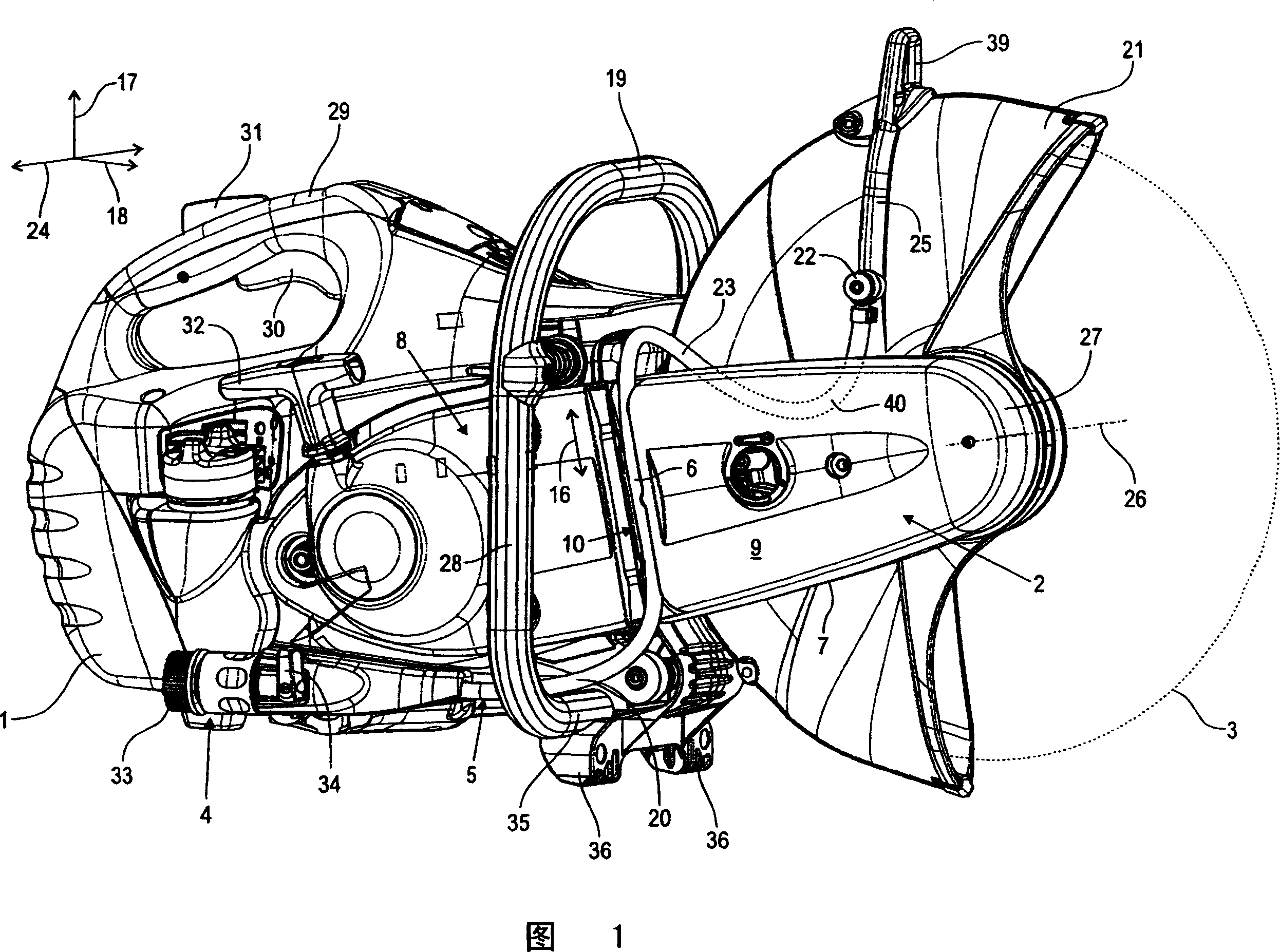

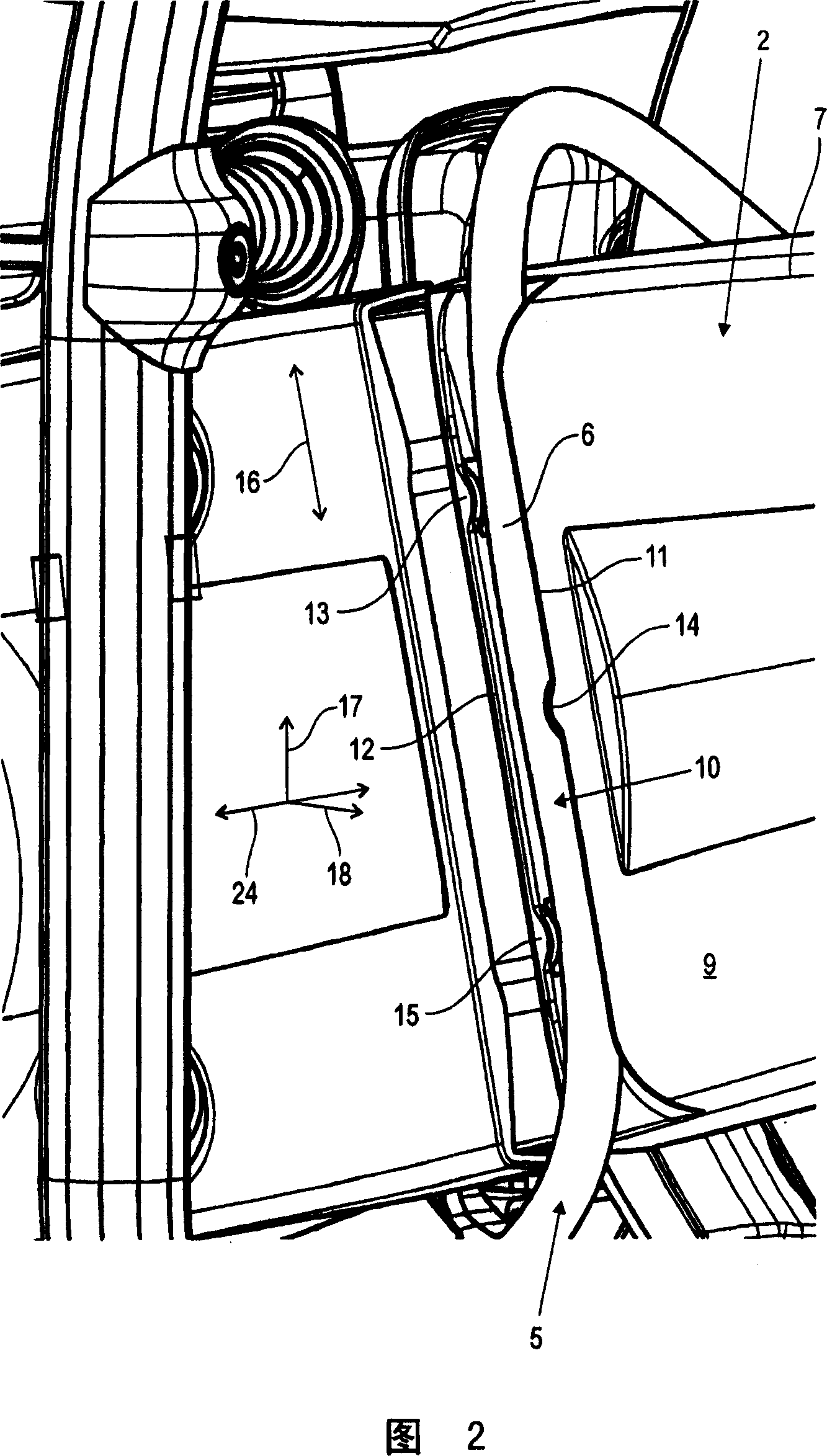

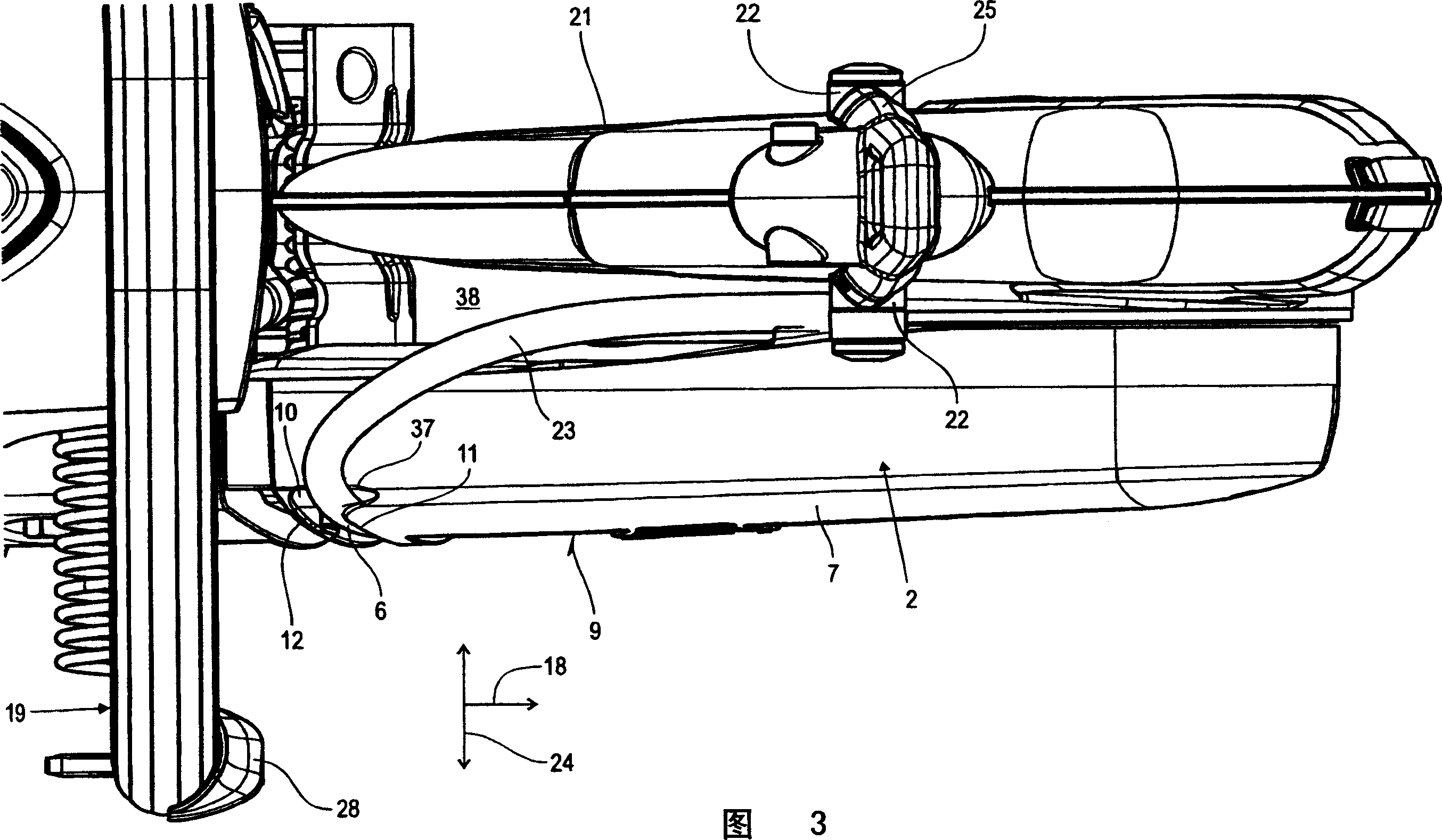

[0019] Fig. 1 shows a perspective view of a portable grinding wheel cutting machine with an engine housing 1, a cantilever 2 and a saw blade grinding wheel 3 manufactured according to the present invention. An unshown drive engine is installed in the engine housing. In the illustrated embodiment, it is an internal combustion engine, but it can also be an electric motor. The grinding wheel cutting machine is drawn in its usual working orientation, where arrows 17, 18, 24 are used. Specify the vertical, longitudinal, and lateral directions.

[0020] A pull switch 32 for starting the internal combustion engine is provided on the side of the engine housing 1, and a rear upper handle 29 is provided on the engine housing 1 toward the user side relative to the vertical direction 17 and the longitudinal direction 18, and a rear upper handle 29 is provided on it. The throttle lever 30 and a throttle lever valve 31 are provided with a front handle tube 19 on the end of the engine housing 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com