Print production technology

A technology of making crafts and prints, which is applied in the fields of crafts for producing decorative surface effects, decorative art, art painting, etc. It can solve the problems of complex crafting, insufficient expressive power, inconvenient installation and hanging, etc., and achieve the goal of crafting Simple, easy to promote and apply, easy to install and hang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

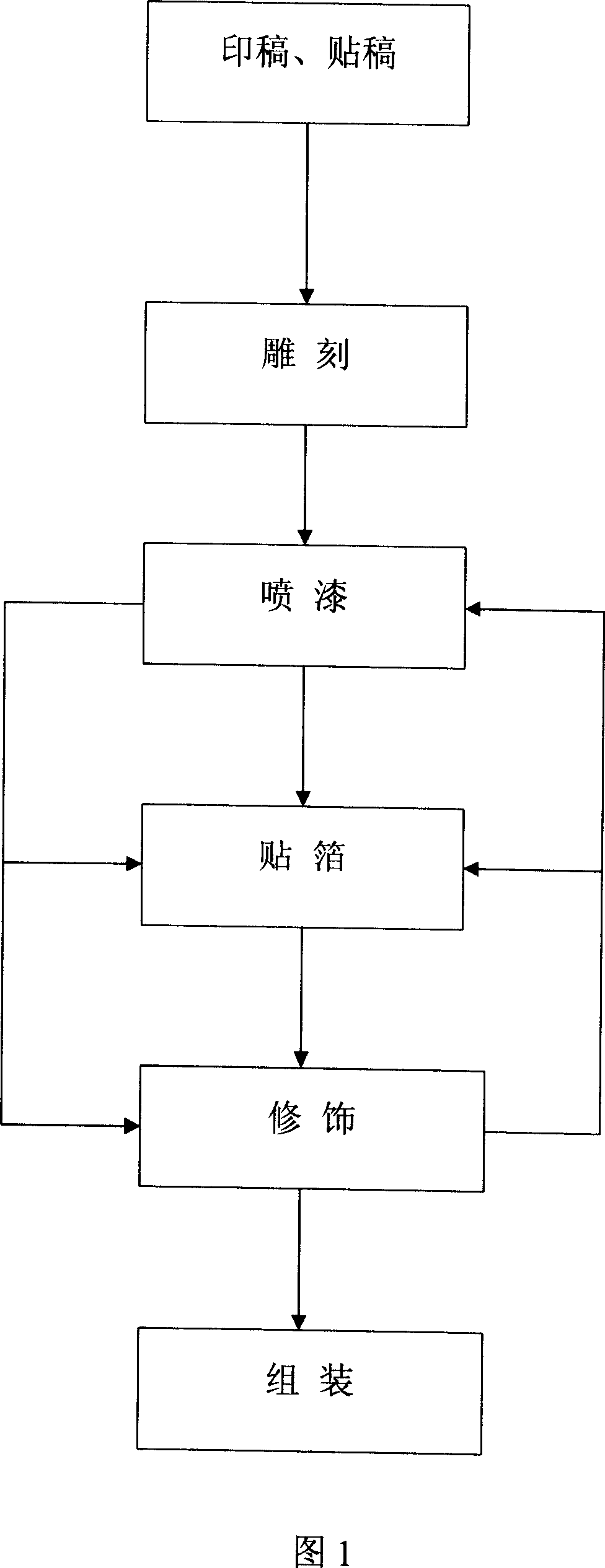

[0021] Embodiment 1: As shown in Figure 1, select the corresponding manuscript sample according to the production instruction, spread the tissue paper for the manuscript on the manuscript sample, and print the manuscript after dipping the ink with the manuscript tool, and drill the hole Put the board flat on the workbench, apply glue on it, and then stick the printed manuscript paper cover on the glue-coated board surface, and then carry out manual carving according to the manuscript paper pattern. After sanding and smoothing, spray the first primer, then sand with 180# sandpaper, spray the first topcoat after sanding, wait until dry and then sand with 180# sandpaper, and then spray the second topcoat after sanding. After painting, the surface must be flat and smooth. In case of anti-whitening, be sure to spray an appropriate amount of whitening water, and do not spray whitening water on products with gold foil.

[0022] Apply glue to the part where the metal foil needs to be...

Embodiment 2

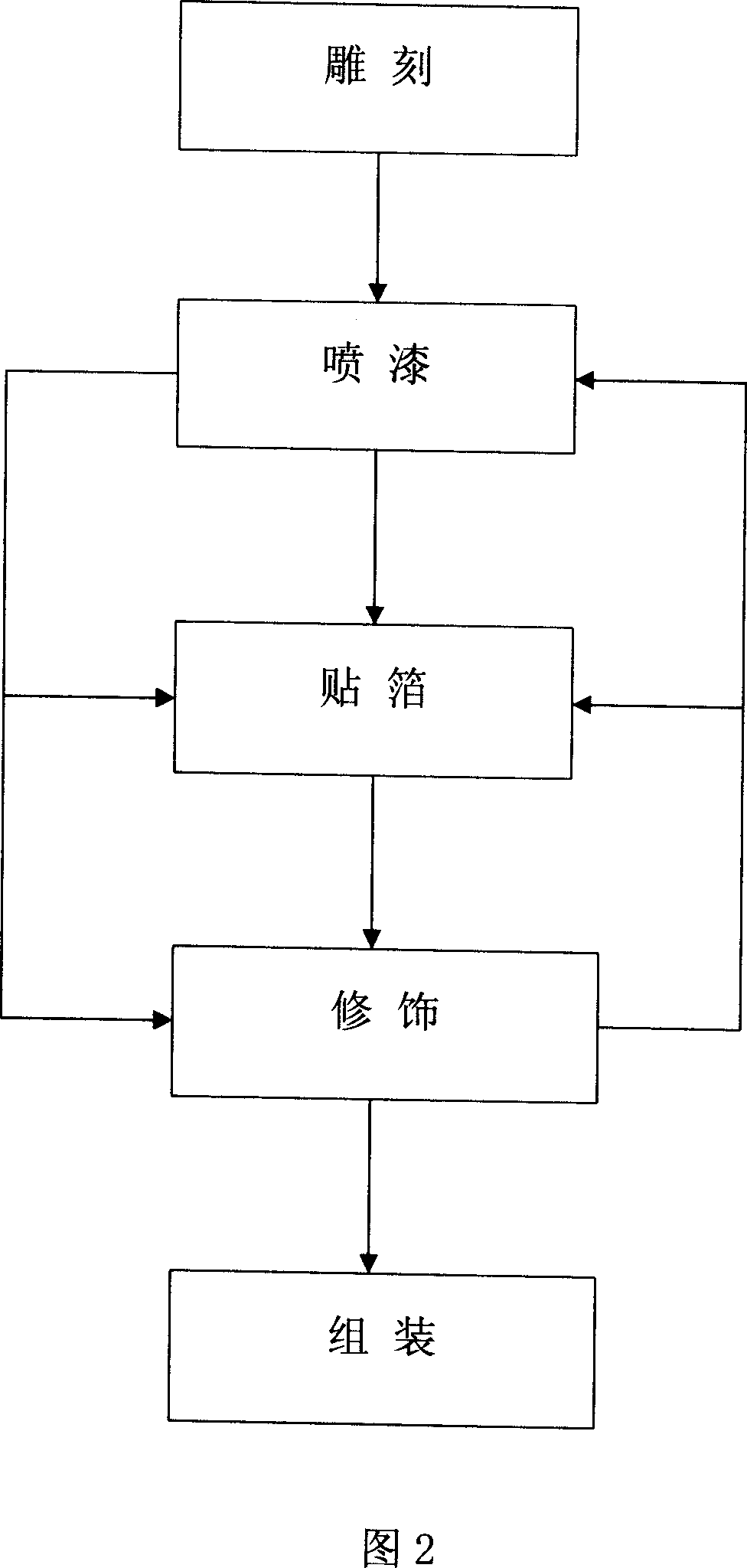

[0024] Embodiment 2: As shown in Figure 2, use an engraving machine to carve concave lines on the board according to the pattern of the model or manuscript paper according to the model, spray the primer for the first time after polishing, and then polish with 180# sandpaper. Spray the top coat for the first time, and then polish it with 180# sandpaper after it dries, and then spray the second top coat after polishing. The surface must be flat and smooth after spraying. In case of anti-whitening, be sure to spray an appropriate amount of whitening water, and do not spray whitening water on products with gold foil.

[0025] Apply glue to the part where the metal foil needs to be pasted, then cover the metal foil on the glue-coated part, and then wipe off the metal foil beyond the glue-coated area with a dry soft cloth. After pasting the foil, be sure to use a stiff brush to pat off the foil dust in the lines. Before attaching the metal foil, check whether the surface of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com