Compressor pump coupling method

A technology of compressor pump and compressor shell, applied in the direction of pump, pump components, mechanical equipment, etc., can solve the problems of reducing the air tightness of compressor shell, affecting the air tightness of welding holes, and leakage of lubricating oil, etc. Eliminate the leakage of lubricating oil, high assembly and processing efficiency, and increase the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now further illustrate specific embodiments of the present invention in conjunction with accompanying drawings.

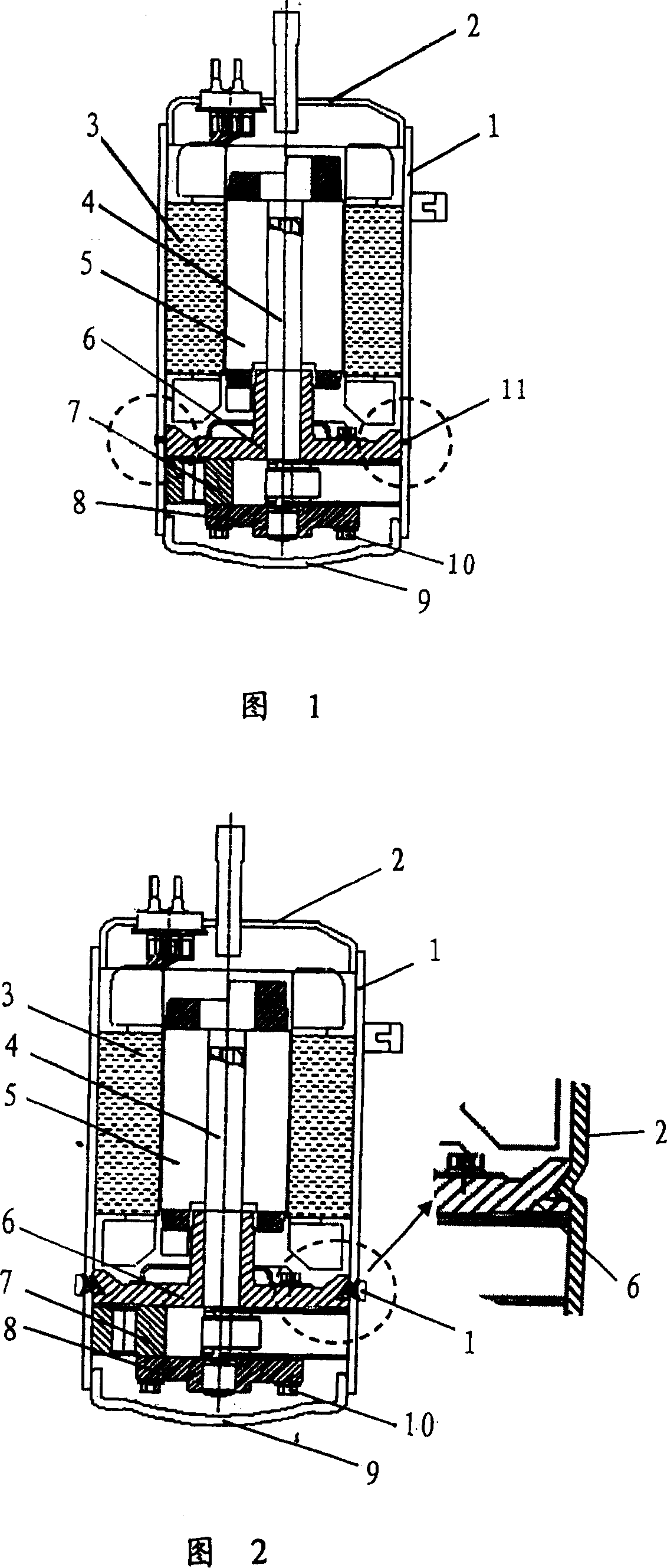

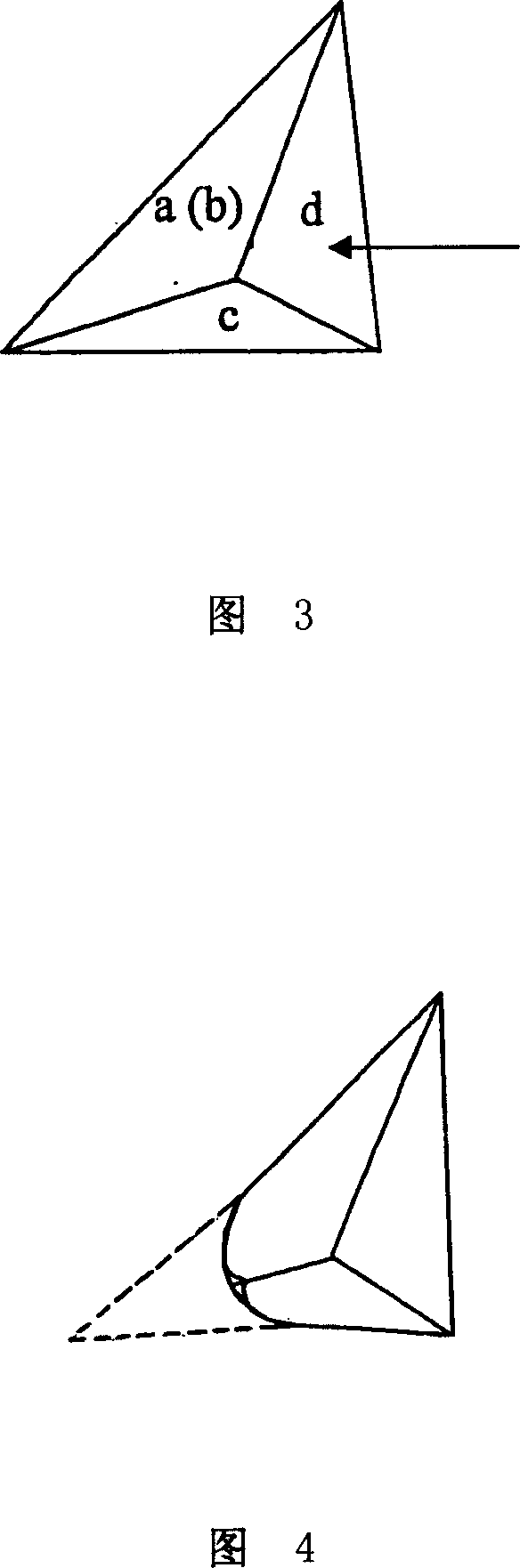

[0028] Fig. 2 shows the structure of the compressor that adopts the present invention to connect the pump body and the casing, Fig. 3 shows the slotted shape of the main bearing of the compressor in the present invention, and Fig. 4 shows the shape of the punch used for stamping the casing according to the present invention.

[0029] The method for connecting the pump body of the compressor involved in the present invention includes two steps of slotting the main bearing and stamping the casing.

[0030] Main bearing slotting: Before the compressor is assembled, four stamping grooves of the shape shown in Figure 3 are processed on the ring-shaped end surface of the main bearing 6 in contact with the housing 1. The four stamping grooves are in orthogonal positions. The inner cavity is tetrahedral in shape. The four triangular faces of the tetrahedron are fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com