Reverting method of low dielectric materials and porous low-dielectric layer

A low-dielectric material, low-dielectric layer technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as the increase in dielectric constant, prevent the operation speed from being reduced, and solve the problem of increasing the dielectric constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

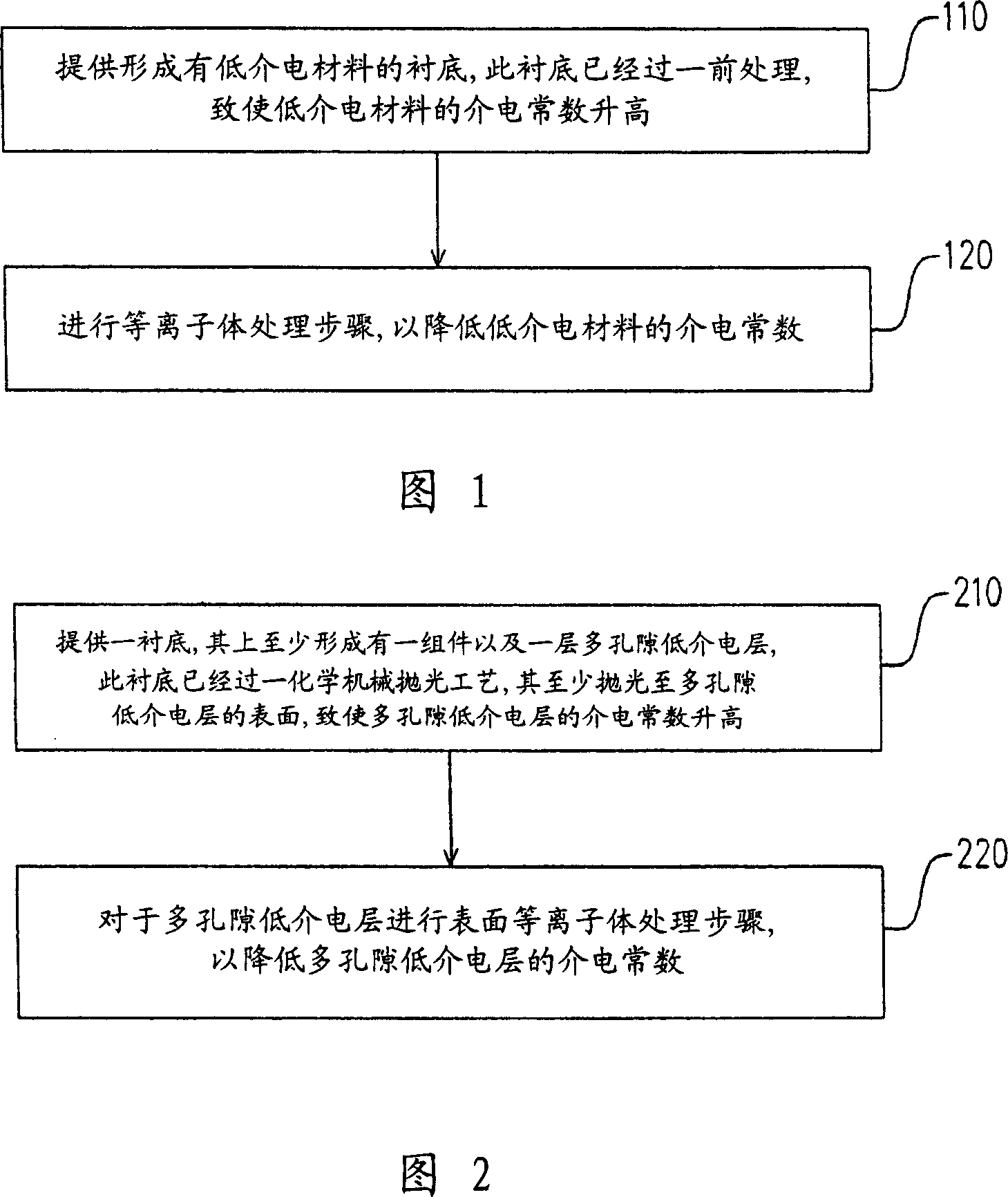

[0030] FIG. 1 is a flowchart illustrating a recovery method for low dielectric materials according to an embodiment of the present invention.

[0031] Referring to FIG. 1 , firstly, a substrate formed with a low-k material is provided, and the substrate has undergone a previous process to increase the dielectric constant of the low-k material (step 110 ). For example, elements such as MOS transistors or memories have been formed in the substrate, and the low dielectric material is, for example, a material constituting an inter-metal dielectric layer (Inter-Metal Dielectric, IMD). The low-dielectric material is, for example, a porous low-dielectric material, such as a pore-forming agent (porogen, whose composition is, for example, C x h y ) carbon doped oxide (Carbon DopedOxide, CDO), fluorinated amorphous carbon, Parylene AF4, PAE or Cyclotene, etc., and its dielectric constant is, for example, between 1.0 and 2.7. The method of forming the low dielectric material is, for ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com